Operating Instructions, complete - W. Gantenbein GmbH

Operating Instructions, complete - W. Gantenbein GmbH

Operating Instructions, complete - W. Gantenbein GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

BUFALO RONDOFIX<br />

� 1 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

Index<br />

1. Preface.................................................................................................................................................... 6<br />

1.1. Safety precautions .............................................................................................................................. 7<br />

2. Description of equipment ........................................................................................................................ 8<br />

2.1. Pupose ................................................................................................................................................ 8<br />

2.1.1. General view ................................................................................................................................ 8<br />

2.1.2. Intended purpose ......................................................................................................................... 9<br />

2.1.3. Responsabilities........................................................................................................................... 9<br />

2.2. Technical data................................................................................................................................... 10<br />

2.2.1. Dimensions ................................................................................................................................10<br />

2.2.2. Weight........................................................................................................................................ 11<br />

2.2.3. Electrical data ............................................................................................................................ 11<br />

2.2.4. Oils, lubricants ........................................................................................................................... 11<br />

2.2.5. Noise emission........................................................................................................................... 11<br />

2.2.6. Ambient conditions..................................................................................................................... 11<br />

2.3. Accessories....................................................................................................................................... 12<br />

3. Security ................................................................................................................................................. 13<br />

3.1. Mandatory reading ............................................................................................................................ 13<br />

3.1.1. Responsibilities .......................................................................................................................... 13<br />

3.1.2. Safety references....................................................................................................................... 13<br />

3.1.3.......................................................................................................................................................... 13<br />

3.1.4. References................................................................................................................................. 14<br />

3.1.5. Meaning of the symbols ............................................................................................................. 14<br />

3.2. Personal classification....................................................................................................................... 15<br />

3.2.1. <strong>Operating</strong> personnel (instructed in control)................................................................................ 15<br />

3.2.2. <strong>Operating</strong> personnel (not instructed in control).......................................................................... 15<br />

3.2.3. Maintenance personnel.............................................................................................................. 15<br />

3.2.4. Service personnel ...................................................................................................................... 15<br />

3.3. Danger zones.................................................................................................................................... 16<br />

3.3.1. Danger zone 1: Delivery station................................................................................................. 16<br />

3.3.2. Danger zone 2: Gluing unit ........................................................................................................ 16<br />

3.3.3. Gefahrenzone 3: Electrics cabinet............................................................................................. 17<br />

3.3.4. Danger zone 4: Cutting station .................................................................................................. 17<br />

3.3.5. Danger zone 5: Paper infeed..................................................................................................... 17<br />

3.4. Positions of the emergency stop switches ........................................................................................ 18<br />

3.5. General safety rules .......................................................................................................................... 19<br />

4. Layout and function .............................................................................................................................. 21<br />

4.1. General layout................................................................................................................................... 21<br />

4.2. Functional principle ........................................................................................................................... 21<br />

4.3. Subassemblies.................................................................................................................................. 22<br />

4.3.1. Infeed station ............................................................................................................................. 22<br />

4.3.2. Cutting station ............................................................................................................................ 23<br />

4.3.3. Fixing station.............................................................................................................................. 24<br />

4.3.4. Gluing station ............................................................................................................................. 25<br />

4.3.5. Pressing station ......................................................................................................................... 26<br />

4.3.6. Conveying system...................................................................................................................... 27<br />

4.3.7. Delivery station .......................................................................................................................... 28<br />

4.3.8. Paper gripper ............................................................................................................................. 29<br />

4.3.9. Dust bag..................................................................................................................................... 30<br />

4.3.10. Controls .................................................................................................................................. 31<br />

4.3.11. Control unit ............................................................................................................................. 32<br />

� 2 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

5. Controls and operating modes.............................................................................................................. 33<br />

5.1. Commissioning the control system ................................................................................................... 33<br />

5.1.1. Turning-on the main switch........................................................................................................ 33<br />

5.1.2. Turning-on the main switch ................................................................................................... 34<br />

5.1.3. Switching-on the drives.............................................................................................................. 34<br />

5.2. Control unit........................................................................................................................................ 35<br />

5.3. <strong>Operating</strong> modes............................................................................................................................... 36<br />

5.3.1. Manual operation ....................................................................................................................... 36<br />

5.3.2. Semiautomatic operation ........................................................................................................... 36<br />

5.3.3. Automatic operation................................................................................................................... 36<br />

5.4. Emergency stopping ......................................................................................................................... 37<br />

5.4.1. Linking other equipment............................................................................................................. 37<br />

6. Commissioning ..................................................................................................................................... 38<br />

6.1. Introduction........................................................................................................................................ 38<br />

6.1.1. Personnel, qualification.............................................................................................................. 38<br />

6.1.2. Technical documentation........................................................................................................... 38<br />

6.1.3. Technical documentation........................................................................................................... 38<br />

6.2. Erecting and testing the machine...................................................................................................... 39<br />

6.2.1. Putting the machine into operation ............................................................................................ 39<br />

6.2.2. Testing the function.................................................................................................................... 39<br />

6.2.3. Acceptance certificate................................................................................................................ 39<br />

7. Operation .............................................................................................................................................. 40<br />

7.1. Control Panel Description ................................................................................................................. 40<br />

7.1.1. „Advance Reverse“ button ......................................................................................................... 40<br />

7.1.2. „Advance Forward“ button ......................................................................................................... 40<br />

7.1.3. „Fixer Forward“ button“ .............................................................................................................. 40<br />

7.1.4. „Fixer Reverse“ button ............................................................................................................... 41<br />

7.1.5. „Raise Press“ Button.................................................................................................................. 41<br />

7.1.6. „Lower Press“ Button ................................................................................................................. 41<br />

7.1.7. „Insert Lining or Cover“ Button................................................................................................... 41<br />

7.1.8. „No Lining or Cover“ Button ....................................................................................................... 41<br />

7.1.9. „Pusher“ Button.......................................................................................................................... 41<br />

7.1.10. „Programme Input“ Button...................................................................................................... 41<br />

7.1.11. „Mode Type Select“ Button .................................................................................................... 41<br />

7.1.12. „Start“ Button .......................................................................................................................... 42<br />

7.2. Switching On the Control System ..................................................................................................... 42<br />

7.3. Operational Mode Selection.............................................................................................................. 43<br />

7.3.1. Manual Operation ...................................................................................................................... 43<br />

7.3.2. Semi or Full Automatic Operation.............................................................................................. 44<br />

7.4. Programme Input .............................................................................................................................. 46<br />

7.4.1. System Settings ......................................................................................................................... 46<br />

7.4.2. Operational Parameters for Prod............................................................................................... 48<br />

7.5. Mechanical adjustments.................................................................................................................... 50<br />

7.5.1. Adjusting the book and glue thickness of the side gluing rollers ............................................... 50<br />

7.5.2. Adjusting the press stroke.......................................................................................................... 52<br />

7.5.3. Paper gripper ............................................................................................................................. 53<br />

7.5.4. Magnetic pusher ........................................................................................................................ 53<br />

7.5.5. Fitting the gauzing station.......................................................................................................... 54<br />

7.5.6. Feed adjustment for gauze or folding station............................................................................. 55<br />

7.5.7. Changing plates for cold and hot glue ....................................................................................... 56<br />

7.6. Error Messages and their Correction ................................................................................................ 57<br />

7.6.1. Control Voltage miss.................................................................................................................. 57<br />

7.6.2. Set V-min ................................................................................................................................... 57<br />

7.6.3. Programme Number .................................................................................................................. 58<br />

7.6.4. Hydraulics and Motors ............................................................................................................... 58<br />

� 3 <strong>Operating</strong>s <strong>Instructions</strong><br />

Bufalo Rondofix V3.0<br />

Edition 22. November 2007

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

7.6.5. Advance Front............................................................................................................................ 58<br />

7.6.6. Advance Rear ............................................................................................................................ 59<br />

7.6.7. Fixer Front.................................................................................................................................. 59<br />

7.6.8. Fixer Rear .................................................................................................................................. 59<br />

7.6.9. Press Down................................................................................................................................60<br />

7.6.10. Safety Shear Cutter................................................................................................................ 60<br />

7.6.11. Safety Glue Unit & Press........................................................................................................ 60<br />

7.6.12. Safety Delivery Station ........................................................................................................... 61<br />

7.6.13. Cover Control ......................................................................................................................... 61<br />

7.6.14. Cover Missing......................................................................................................................... 61<br />

7.6.15. Ejection................................................................................................................................... 62<br />

7.6.16. Delivery Station ...................................................................................................................... 62<br />

7.6.17. Light curtain............................................................................................................................ 63<br />

7.6.18. Safety ejection........................................................................................................................ 63<br />

8. Maintenance ......................................................................................................................................... 65<br />

8.1. Introduction........................................................................................................................................ 65<br />

8.2. Oils, lubricants................................................................................................................................... 65<br />

8.2.1. Oils, lubricants ........................................................................................................................... 65<br />

8.3. Maintenance schedule ...................................................................................................................... 66<br />

8.3.1. Cleaning shafts for gluing rollers ............................................................................................... 66<br />

8.3.2. Lubricating the Cardan shaft...................................................................................................... 67<br />

9. Servicing ............................................................................................................................................... 68<br />

9.1. Adjusting cutter clearance................................................................................................................. 68<br />

9.1.1. Clearance from plate.................................................................................................................. 68<br />

9.1.2. Clearance from back rest........................................................................................................... 69<br />

9.2. Cleaning the cooler ........................................................................................................................... 70<br />

9.3. Adjusting limit switches ..................................................................................................................... 71<br />

9.3.1. Right-hand limit switch ............................................................................................................... 71<br />

9.3.2. Left-hand limit switch ................................................................................................................. 72<br />

9.4. Adjusting the chain tensioner............................................................................................................ 73<br />

9.5. Limiting the press plate opening ....................................................................................................... 74<br />

9.6. Plate adjustment ............................................................................................................................... 75<br />

9.7. Adjusting the feed piston................................................................................................................... 76<br />

9.8. Ejector speed .................................................................................................................................... 77<br />

9.9. Brake adjustment .............................................................................................................................. 78<br />

9.10. Height adjustment of the gluing unit.................................................................................................. 79<br />

9.11. Interlocking........................................................................................................................................ 80<br />

10. Decommissioning, storage ................................................................................................................... 81<br />

10.1. Introduction........................................................................................................................................ 81<br />

10.1.1. Personnel, qualification .......................................................................................................... 81<br />

10.1.2. Storage conditions.................................................................................................................. 81<br />

10.2. Storage lasting more than six months............................................................................................... 81<br />

10.2.1. Preparations ........................................................................................................................... 81<br />

10.2.2. Maintenance during storage................................................................................................... 81<br />

11. Packing and transport........................................................................................................................... 82<br />

11.1. Preparations...................................................................................................................................... 82<br />

11.2. Packing.............................................................................................................................................. 82<br />

11.3. Transport........................................................................................................................................... 83<br />

11.3.1. Data for transportation............................................................................................................ 83<br />

11.3.2. Fixing points ........................................................................................................................... 83<br />

11.3.3. Transport by fork-lift ............................................................................................................... 84<br />

� 4 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

12. Disposal ................................................................................................................................................ 85<br />

12.1. Introduction........................................................................................................................................ 85<br />

12.1.1. Personnel, qualification .......................................................................................................... 85<br />

12.2. Preparations for disposal .................................................................................................................. 86<br />

� 5 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

1. Preface<br />

These operating instructions were issued in September 1998<br />

Updating status<br />

Section Title Date<br />

1 Preface 1 st edition 9/1998<br />

2 Description of equipment 1 st edition 9/1998<br />

3 Security 1 st edition 9/1998<br />

4 Layout and function 1 st edition 9/1998<br />

5 Controls and operating modes 2 st edition 3/2001<br />

6 Installation and commissioning 2 st edition 3/2001<br />

7 Operation 2 st edition 3/2001<br />

8 Maintenance 1 st edition 9/1998<br />

9 Servicing 1 st edition 9/1998<br />

10 Storage 1 st edition 9/1998<br />

11 Transport and packing 1 st edition 9/1998<br />

12 Disposal 1 st edition 9/1998<br />

Copyright © W. <strong>Gantenbein</strong> Maschinenbau <strong>GmbH</strong><br />

Subject to technical alterations without notification.<br />

No part of this documentation may be stored electronically, transferred or duplicated in any way<br />

without the prior approval in writing of W. <strong>Gantenbein</strong> Maschinenbau <strong>GmbH</strong>. This applies also to<br />

photocopying, photographing, and recording on magnetic or other data carriers, though it is not<br />

restricted to the aforenamed reproduction methods. Non-compliance will entail liability for damages.<br />

� 6 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

1.1. Safety precautions<br />

The BUFALO RONDOFIX may be operated, maintained and serviced only by instructed<br />

personnel possessing the necessary technical qualifications.<br />

The operator is responsible for all persons involved being appropriately trained.. Further<br />

details is situated in the chapters 2.<br />

The firm of W. <strong>Gantenbein</strong> Maschinenbau <strong>GmbH</strong> declines all liability for any damage resulting<br />

from failure to fulfill these conditions.<br />

Before commissioning the BUFALO-RONDOFIX, Section 3 and the security instructions<br />

contained in it must have been read and understood.<br />

� 7 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

2. Description of equipment<br />

2.1. Pupose<br />

Brief description: This section defines the intended purpose of the equipment and<br />

provides an overview of the performance scope, technical data and accessories of the<br />

BUFALO RONDOFIX.<br />

2.1.1. General view<br />

9<br />

8<br />

Fig. 1 General view<br />

1<br />

2<br />

1. Infeed station<br />

2. Cutting station<br />

3. Fixing station<br />

4. Control unit<br />

5. Gluing station<br />

6. Pressing station (optionally with folding station/gauzing station/cover station)<br />

7. Delivery station<br />

8. Circulating containers<br />

9. Dust bag<br />

� 8 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

3<br />

4<br />

5<br />

6<br />

7

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

2.1.2. Intended purpose<br />

The BUFALO RONDOFIX is intended for casing-in, i.e. folding or gauzing books<br />

brochures, blocks and other pressed, stacked or bound materials.<br />

Indication<br />

If the machine is used for any other than the purpose defined here without the<br />

written approval of the maker, or if it is operated outside its technical limits (see<br />

Technical Data), the maker will accept no liability for any damage or injury resulting<br />

therefrom.<br />

2.1.3. Responsabilities<br />

• Personnel<br />

It is the operator's responsibility that everyone charged with the operation,<br />

maintenance or servicing of the BUFALO RONDOFIX has read and understood<br />

the relevant parts of these operating instructions.<br />

• Instruction and training<br />

The BUFALO RONDOFIX may be operated, maintained and serviced only by<br />

instructed personnel having the necessary technical qualifications. The operator is<br />

responsible for organizing and holding the necessary instruction courses.<br />

• Security<br />

The BUFALO RONDOFIX is equipped with the necessary interlocks and safety<br />

devices in accordance with international regulations. Nevertheless the machine<br />

may present dangers if the safety precautions set out in Section 3 are not followed.<br />

These precautions and the safety-relevant instructions in the individual sections<br />

must be observed meticulously by the operator and the users. In particular the<br />

machine operator is responsible for the protection of persons and the prevention of<br />

material damage.<br />

� 9 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

2.2. Technical data<br />

2.2.1. Dimensions<br />

2020<br />

730<br />

� 10 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

5110<br />

3410<br />

Fig.2 Dimensions of the BUFALO RONDOFIX<br />

650<br />

3000<br />

Fig. 3 Dimensions of the dust bag<br />

770

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

2.2.2. Weight<br />

Machine ca. 2100 kg<br />

Dust bag ca. 25 kg (empty)<br />

2.2.3. Electrical data<br />

Power supply Total 17 KW, 40 A<br />

Voltage 3 x 400 V<br />

Connecting leads L1, L2, L3, N, PE<br />

Frequency 50 Hz<br />

Current (fused by customer) 40 A<br />

Power max. 20 KW<br />

2.2.4. Oils, lubricants<br />

Oil BP Bartran SHF-S 46 / Blaser HVLP 46<br />

2.2.5. Noise emission<br />

The noise level ranges up to 75 dBA<br />

2.2.6. Ambient conditions<br />

Ambient temperature 10 - 40°C<br />

Air humidity 0 - 90 %<br />

� 11 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

2.3. Accessories<br />

>25 kg<br />

Gauzing or folding station<br />

Suction feeder<br />

Accessory parts weighing more than 25 kg or of bulky shape must be fitted<br />

by two persons.<br />

The gauzing and folding station accessories and the suction feeder each<br />

weigh more than 25 kg.<br />

� 12 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

3. Security<br />

Brief description: This section explains the safety concept of the BUFALO<br />

RONDOFIX. It defines the responsibilities of the operator and the security<br />

directives stated in these instructions.<br />

3.1. Mandatory reading<br />

Section 3 must be read by all persons involved in the installation, operation, maintenance and<br />

servicing of thr BUFALO RONDOFIX.<br />

3.1.1. Responsibilities<br />

The operator is responsible that all persons charged with the operation, maintenance<br />

or servicing of the BUFALO RONDOFIX have read and understood the relevant parts<br />

of these operating instructions<br />

The BUFALO RONDOFIX may be operated, maintained and serviced only by<br />

instructed personnel having the necessary technical qualifications. The operator is<br />

responsible for organizing and holding the necessary instruction courses.<br />

The operator is in addition responsible for:<br />

• keeping unauthorized persons away from the BUFALO RONDOFIX;<br />

• instructing the personnel about the potential risks and dangers when installing,<br />

operating, maintaining or servicing the BUFALO RONDOFIX as described in these<br />

instructions;<br />

• the strict observance of the technical specifications and safety instructions set out<br />

in Section 2.2 (Technical Data).<br />

3.1.2. Safety references<br />

3.1.3.<br />

The safety references that follow draw attention to the various danger levels and<br />

important technical requirements in the individual sections.<br />

Dangers possibly causing serious injuries or death.<br />

Dangers likely to cause light to medium injuries, substantial material<br />

damage or environmental offence.<br />

� 13 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

3.1.4. References<br />

References in the form shown below draw attention to technical requirements and tips<br />

in the individual sections.<br />

3.1.5. Meaning of the symbols<br />

Indication<br />

<strong>Instructions</strong> on handling or use. Failure to follow them may lead to<br />

troubles or minor material damage.<br />

The following symbols are used in the operating instructions and on the machine.<br />

They mean:<br />

Warning: dangerous voltage<br />

Warning: hot surface<br />

Warning: injury to hands<br />

Warning: strong noise emission<br />

� 14 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

3.2. Personal classification<br />

Depending on its training and authorization the personnel is classified as operational,<br />

maintenance and servicing. The operating personnel is subdivided into two categories:<br />

3.2.1. <strong>Operating</strong> personnel (instructed in control)<br />

The operating personnel may operate the BUFALO RONDOFIX in the automatic<br />

mode, which involves the following activities:<br />

• feeding the machine with unbound materials and removing the bound materials;<br />

• setting stops;<br />

• using the control system in the operating mode (switching-on, starting, program<br />

selection etc.);<br />

• cleaning<br />

3.2.2. <strong>Operating</strong> personnel (not instructed in control)<br />

The operating personnel may operate the BUFALO RONDOFIX in the automatic<br />

mode, involving the following activities:<br />

• feeding the machine with unbound materials and removing the bound materials;<br />

• cleaning.<br />

3.2.3. Maintenance personnel<br />

The maintenance personnel may operate the BUFALO RONDOFIX in the normal<br />

mode and in addition perform maintenance tasks necessary to ensure trouble-free<br />

operation. Maintenance includes the following tasks among others:<br />

• lubricating chains and Cardan shaft<br />

• checking the oil level.<br />

• all tasks described in the section on maintenance.<br />

To be able to maintain the BUFALO RONDOFIX the maintenance personnel must<br />

have been instructed by a co-worker or an experienced and responsible employee of<br />

the plant operator.<br />

3.2.4. Service personnel<br />

The service personnel may operate the BUFALO RONDOFIX in the normal mode and<br />

perform maintenance and servicing work.<br />

• All activities described in the section on servicing.<br />

The BUFALO RONDOFIX may be serviced only by trained employees of W. <strong>Gantenbein</strong><br />

Maschinenbau <strong>GmbH</strong>, a representative of this firm or trained employees of the<br />

plant operator with equivalent proficiency.<br />

For working on electrical components a training as master electrician or equivalent is<br />

necessary.<br />

� 15 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

3.3. Danger zones<br />

The critical danger zones are shown in the illustration below.<br />

Fig. 4 Danger zones<br />

3.3.1. Danger zone 1: Delivery station<br />

• Danger from moving mechanical parts.<br />

3.3.2. Danger zone 2: Gluing unit<br />

5<br />

� 16 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

4<br />

Danger from moving mechanical parts.<br />

Do not reach under the protective hood.<br />

Danger from glue temperature up to 200°C.<br />

Do not reach into the gluing unit during operation.<br />

3<br />

2<br />

1

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

Danger from possible vapours.<br />

3.3.3. Gefahrenzone 3: Electrics cabinet<br />

Read and note the safety instructions of the glue supplier.<br />

Suctioning or other precautions may be necessary to avoid possible<br />

danger to health.<br />

Warning: Voltage<br />

3.3.4. Danger zone 4: Cutting station<br />

3.3.5. Danger zone 5: Paper infeed<br />

Turn off the main switch before working on the electrical installation.<br />

Considerable noise is set up when cutting and roughening the book<br />

spines.<br />

Always wear hearing protection while working.<br />

Warning: Paper gripper moves down.<br />

Do not reach into the path of the downcoming gripper.<br />

� 17 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

3.4. Positions of the emergency stop switches<br />

The positions of the emergency stop switches are shown in the illustration below.<br />

Fig. 5 Emergency stop switches<br />

1. Emergency stop switch at infeed station<br />

2. Emergency stop switch on control unit<br />

2<br />

� 18 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

1

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

3.5. General safety rules<br />

The following rules must be strictly observed.<br />

• Use as intended<br />

See subsection 2.1.2<br />

• Maker's specifications<br />

The application specifications include also the observance of the regulations for<br />

commissioning, maintaining and servicing the BUFALO RONDOFIX.<br />

• Personnel training<br />

The BUFALO RONDOFIX may be installed, operated (commissioned), maintained and<br />

serviced only by trained personnel. These people must have been instructed about the<br />

dangers associated with the machine.<br />

• Delimitation of responsibility<br />

The responsibilities and competences must be established clearly prior to installation,<br />

operation, maintenance or servicing work, and they must be adhered to under all<br />

Circumstances.<br />

• Misuse<br />

It is absolutely wrong to operate the BUFALO RONDOFIX in such a way that injury to<br />

persons or material damage may ensue.<br />

• Inaccessibility for unauthorized or untrained persons<br />

It is the operator's responsibility that the BUFALO RONDOFIX can be used only by trained<br />

persons.<br />

• Impermissible modifications<br />

Modifications or design alterations detrimental to the security or reliability of the BUFALO<br />

RONDOFIX are not allowed. W. <strong>Gantenbein</strong> Maschinenbau <strong>GmbH</strong> must be contacted<br />

before attempting any modifications.<br />

• Registration of modifications<br />

The operator is under obligation to notify W. <strong>Gantenbein</strong> Maschinenbau <strong>GmbH</strong> at once of<br />

modifications to the BUFALO RONDOFIX, especially if the security or reliability of the<br />

machine might be affected.<br />

• Maintenance obligation<br />

The operator must ensure that the BUFALO RONDOFIX is operated only under admissible<br />

conditions and in perfect state.<br />

• Working area<br />

The operator must ensure that the BUFALO RONDOFIX is freely accessible on all sides for<br />

all necessary work.<br />

� 19 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

• Transport and installation<br />

The BUFALO RONDOFIX may be transported only in its original packing and lifted only by<br />

the points provided. Installation must be performed exclusively by technically qualified<br />

personnel. The relevant installation instructions must be followed strictly.<br />

• Switching-off<br />

The BUFALO RONDOFIX must be switched off <strong>complete</strong>ly for all maintenance and<br />

servicing work, to ensure that all parts of it are dead whilst working.<br />

• Removing safety devices<br />

Safety devices may be removed only when the machine is switched off and its power<br />

supply cut off. The safety devices must be properly fitted again before restoring the power<br />

supply.<br />

• Checks after maintenance or servicing<br />

After any installation, maintenance or servicing work all safety circuits (e.g. interlocks) must<br />

be checked to ensure that they function properly. Above all, after electrical installation or<br />

servicing the safety provisions must be tested (e.g. earthing, insulation resistance etc.). The<br />

BUFALO RONDOFIX may be put back into operation only after successful checking.<br />

• Connections to the BUFALO RONDOFIX<br />

Electrical connecting leads must be protected against all kinds of mechanical damage. The<br />

leads must affect neither the security nor the reliability of the machine, nor working on it.<br />

• Organizational measures<br />

These operating instructions must be kept accessible at all times at a place near to the<br />

BUFALO RONDOFIX.<br />

• Specific safety regulations<br />

Local regulations and specific safety regulations applying to industrial equipment must<br />

likewise be observed when operating the BUFALO RONDOFIX.<br />

� 20 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

4. Layout and function<br />

4.1. General layout<br />

Brief description: This section explains the safety concept of the BUFALO<br />

RONDOFIX. It defines the responsibilities of the operator and the security<br />

directives stated in these instructions.<br />

The BUFALO RONDOFIX consists essentially of two associated subsystems:<br />

• Production machine<br />

• Dust bag<br />

9<br />

8<br />

1<br />

2<br />

Fig. 6 Overall view<br />

1. Infeed station<br />

2. Cutting station<br />

3. Fixing station<br />

4. Control unit<br />

5. Gluing station<br />

6. Pressing station (optionally with folding station/gauzing station/cover station)<br />

7. Delivery station<br />

8. Circulating container<br />

9. Dust bag<br />

4.2. Functional principle<br />

The unbound book block or unbound brochure is led to the gripping jaws, thereby actuating a<br />

contact that triggers in the correct sequence all motions needed for the working operation.<br />

After inserting the first brochure the start key must then be pressed, likewise after the<br />

economy circuit responds.<br />

� 21 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

3<br />

4<br />

5<br />

6<br />

7

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

6<br />

4.3. Subassemblies<br />

4.3.1. Infeed station<br />

At this station the paper to be bound is placed in the paper gripper.<br />

59 57 55 53 51 49 47 45 43 41 39 37 35 33 31 29 27 25 23 21 19 17 15 13 9 7<br />

5<br />

4<br />

Fig. 7 Infeed station<br />

� 22 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

3<br />

1. Start trigger 4. Inclination adjustment<br />

2. Emergency stop switch 5. Cutting depth adjustment<br />

3. Infeed table 6. Fixing lever<br />

6<br />

5<br />

4<br />

Abbildung 8 Cutting depth adjustment<br />

1<br />

Infeed table with sensor-controlled start triggering. At this station the cutting depth is<br />

adjusted from 0 mm to 5.6 mm for stitched book blocks, and the inclination is adjusted<br />

too.<br />

2

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

4.3.2. Cutting station<br />

At this station the book or brochure spines are routed off to the preadjusted height.<br />

4<br />

Fig. 9 Cutting station<br />

1. Adjusting screw<br />

2. Cover plate<br />

3. Grinding wheel<br />

4. Cutter<br />

5. Cutter cover<br />

3<br />

The spine cutter consists of a hard metal cutter blade with overarm. The fold is cut<br />

away and then roughened by the grinding wheel and the fibres felted.<br />

� 23 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

2<br />

5<br />

1

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

4.3.3. Fixing station<br />

The spine and end piece of the book or brochure to be bound are provided with<br />

regular, crosswise dovetail cuts in the fixing unit.<br />

59 57 55 53 51 49 47 45 43 41 39 37 35 33 31 29 27 25 23 21 19 17 15 13 9<br />

Fig 10 Fixing station<br />

1. Cutter<br />

2. Height adjustment<br />

3. Cover plate<br />

3<br />

2<br />

� 24 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

1<br />

The fixing unit cuts crosswise grooves .8 mm wide into the spine, adjustable in depth<br />

up to 1 mm, into which the glue penetrates like a thread. This gives a strengthened<br />

binding.<br />

7

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

4.3.4. Gluing station<br />

The gluing station serves to apply glue onto the spine of the book or brochure.<br />

12<br />

11<br />

1 2 3 4 5 6 7<br />

Fig. 11 Gluing station<br />

1. Glue thickness adjustment for gluing roller 1<br />

2. Gluing roller 1<br />

3. Glue thickness adjustment for gluing roller 2<br />

4. Gluing roller 2<br />

5. Glue wiper adjustment<br />

6. Height adjustment for gluing unit<br />

7. Height adjustment for side gluing<br />

8. Side gluing roller<br />

9. Gluing wheel<br />

10. Heating for hot glue (optional)<br />

11. Lifting device for glue pot<br />

12. Thermostat for glue pot (for hot glue heating)<br />

• Cold gluing<br />

The glue is applied by two rollers for the spine and two side gluing rollers.<br />

• Hot gluing<br />

There is a choice between a one-piece and a two-piece glue pot. With two-piece<br />

glue pots it is possible to use different glues simultaneously for the spine and<br />

sides. The glue is kept at the right temperature by thermostats.<br />

� 25 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

8<br />

9<br />

10

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

4.3.5. Pressing station<br />

The pressing station serves to press the books or brochures being produced<br />

(pressing-on the covers).<br />

3<br />

2<br />

59 57 55 53 51 49 47 45 43 41 39 37 35 33 31 29 27 25 23 21 19 17 15 13 9<br />

Fig. 12 Pressing station<br />

1. Front pressing plate<br />

2. Rear pressing plate<br />

3. Pressing table<br />

1<br />

7<br />

On the standard BUFALO RONDOFIX the covers are fed in manually and pressed on<br />

from below and the side by a hydraulic press. Pressing time may be varied between<br />

0.5 and 5 seconds by the control system. Thanks to the high pressing force of 100 kg,<br />

covers weighing up to 300 g can be handled without scoring.<br />

To press on a cover, first the lower pressing plate moves up and presses the cover<br />

against the spine. Then the front and rear pressing plates move together, pressing the<br />

cover against the side glue.<br />

� 26 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

4.3.6. Conveying system<br />

The conveying system takes the finished books and brochures to the delivery station.<br />

3<br />

Fig. 13 Conveying system<br />

1. Hand wheel<br />

2. Conveying system<br />

3. Conveyor belt<br />

2<br />

59 57 55 53 51 49 47 45 43 41 39 37 35 33 31 29 27 25 23 21 19 17 15 13 9 7<br />

With the hand wheel the spacing of the conveying system is matched to the book<br />

width.<br />

The station has an ejection sensor that stops the machine if there is still a book in the<br />

paper gripper after passing the ejection.<br />

� 27 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

1

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

4.3.7. Delivery station<br />

The delivery station serves to dry the books or brochures.<br />

59 57 55 53 51 49 47 45 43 41 39 37 35 33 31 29 27 25 23 21 19 17 15 13 9 7<br />

4 3<br />

Fig. 14 Delivery station<br />

1. Heatable delivery (for cold glue only)<br />

2. Ejector<br />

3. Valve for heated delivery<br />

4. Counter (optical sensor))<br />

5. Safety hood<br />

On their way to the heated delivery the books are counted eelctronically. They are<br />

then positioned for drying standing on their spines.<br />

Fig. 15 Delivery station<br />

� 28 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

2<br />

1<br />

5<br />

In Fig. 10 the valve [3] is shown in the<br />

heating position for cold glue.

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

4.3.8. Paper gripper<br />

The circulating paper grippers take up the paper to bring it to the working stations.<br />

59 57 55 53 51 49 47 45 43 41 39 37 35 33 31 29 27 25 23 21 19 17 15 13 9<br />

1<br />

4<br />

Fig. 16 Paper gripper<br />

1. Gripper spacing adjustment<br />

2. Support<br />

3. Scale<br />

4. Spine length stop<br />

3<br />

7<br />

2<br />

� 29 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

1

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

4.3.9. Dust bag<br />

The dust bag takes up the suctioned paper wastes (shavings, dust etc.)<br />

3<br />

2<br />

1<br />

Abbildung 17 Suction hose<br />

1. Stand<br />

2. Waste bag<br />

3. Filter bag<br />

4. Suction hose<br />

� 30 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

4

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

4.3.10. Controls<br />

The controls shown below control and regulate all functions of the machine.<br />

1 2 3 4 5 6 7<br />

7 8 9<br />

ALARM<br />

SYST<br />

4 5 6<br />

SYST<br />

1 2 3<br />

Start<br />

ALARM<br />

+/– 0 .<br />

� 31 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

DEL<br />

ESC +1 MENU<br />

MOD<br />

SHIFT -1 ENTER<br />

Fig. 18 Controls<br />

1. Advance speed<br />

2. Main switch<br />

3. Control voltage switch-on/off<br />

4. Control unit<br />

5. Counter<br />

6. Emergency stop switch<br />

7. Thermostat control for hot gluing (optional)<br />

MAGELiS<br />

Stop

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

4.3.11. Control unit<br />

The control unit accommodates the display, operating and controls for the BUFALO<br />

RNDOFIX.<br />

ALARM<br />

ESC<br />

SHIFT<br />

+1<br />

SYST<br />

MOD<br />

-1<br />

� 32 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

MENU<br />

ALARM<br />

ENTER<br />

DEL<br />

7<br />

8 9<br />

4 5 6<br />

1 2 3<br />

+/– 0 .<br />

5 4<br />

3<br />

Fig. 19 Control unit<br />

1. Display<br />

2. Control key<br />

3. Numeric keypad<br />

4. Function keys<br />

5. Manual operation keys<br />

SYST<br />

1<br />

Start<br />

MAGELiS<br />

2<br />

Stop

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

5. Controls and operating modes<br />

Brief description: This section explains the safety concept of the BUFALO<br />

RONDOFIX. It defines the responsibilities of the operator and the security<br />

directives stated in these instructions.<br />

5.1. Commissioning the control system<br />

1 2 3 4 5<br />

DEL<br />

ESC +1 MENU<br />

MOD<br />

SHIFT -1 ENTER<br />

ALARM<br />

SYST<br />

SYST<br />

ALARM<br />

MAGELiS<br />

7 8 9<br />

4 5 6<br />

1 2 3<br />

Start<br />

+/– 0 .<br />

Fig. 20 Control console<br />

1. Main switch<br />

2. Control voltage switch-on/off<br />

3. Control unit<br />

4. Counter<br />

5. Emergency stop switch<br />

The machine has a lockable main switch.<br />

Stop<br />

The main switch can be secured in the OFF position for servicing purposes, using up<br />

to 3 padlocks.<br />

5.1.1. Turning-on the main switch<br />

To put the machine into operation the main switch must be turned on. If it is secured<br />

with more than one padlock, these must be removed by the people who attached<br />

them.<br />

The main switch is turned on by turning it clockwise.<br />

� 33 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

5.1.2. Turning-on the main switch<br />

After turning on the main switch the control voltage can be switched on by pressing<br />

the green button [2], though this is possible only if no emergency stop switch has been<br />

operated and the covering over the cutter is closed. Emergency stop switches once<br />

pressed are released by turning them.<br />

The green button [2] lights when the control voltage is switched on.<br />

5.1.3. Switching-on the drives<br />

Upon switching-on the control voltage the motors driving the various subunits are put<br />

into operation automatically.<br />

These drives are switched off automatically after running more than 5 minutes without<br />

load.<br />

The drives are switched on again automatically by operating a button or switch for<br />

manual or automatic operation on the control unit [3].<br />

� 34 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

5.2. Control unit<br />

ALARM<br />

ESC<br />

SHIFT<br />

+1<br />

SYST<br />

MOD<br />

-1<br />

MENU<br />

ALARM<br />

ENTER<br />

� 35 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

DEL<br />

7<br />

8 9<br />

4 5 6<br />

1 2 3<br />

+/– 0 .<br />

5 4<br />

3<br />

SYST<br />

Fig. 21 Control unit<br />

1. Display<br />

2. Control keys<br />

3. Numeric keys<br />

4. Function keys<br />

5. Manual operation keys<br />

1<br />

Start<br />

MAGELiS<br />

For a full description of the functions see subsection 7.1: Control Unit.<br />

2<br />

Stop

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

5.3. <strong>Operating</strong> modes<br />

5.3.1. Manual operation<br />

In manual operation all subassemblies of the BUFALO RONDOFIX can be operated<br />

singly with the function keys [4] and manual operation keys[5] (for full details see<br />

Section 7).<br />

5.3.2. Semiautomatic operation<br />

In semiautomatic operation each movement of the machine must be triggered by<br />

pressing the starting key. In this way the machine cycle can be run through stepwise<br />

(for more details see Section 7).<br />

5.3.3. Automatic operation<br />

In automatic operation only the first cycle must be started by pressing the starting key<br />

after inserting the book. The next cycle is started automatically by inserting the second<br />

book. Readiness is signalled by the diode lighting in the starting key (for fully<br />

description see Section 7).<br />

� 36 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

5.4. Emergency stopping<br />

Indication<br />

The emergency stop switch is effective in every operating mode. It serves to<br />

shut down the machine in dangerous situations. Every an emergency stop all<br />

subunits are without power.<br />

<strong>Operating</strong> the emergency stop switch cuts out the control voltage. This must be<br />

restored again after releasing the emergency stop switch by pressing the ON key.<br />

Opening the safety covers over the fixing station will also trigger an emergency stop.<br />

After closing the covers the control voltage must be switched on again.<br />

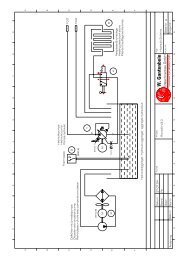

5.4.1. Linking other equipment<br />

If the EMERGENCY STOP circuit of other equipment is to be linked with the safety<br />

circuit of the BUFALO RONDOFIX, terminals have been provided for this. The<br />

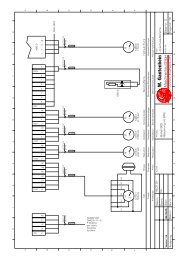

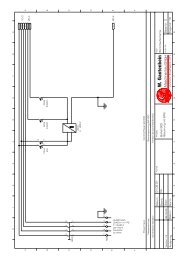

connections are shown in the electrical diagram.<br />

The control system of the BUFALO RONDOFIX gives a pulse signal to other<br />

equipment.<br />

� 37 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

6. Commissioning<br />

6.1. Introduction<br />

Brief description: This section provides information for successfully installing and<br />

commissioning. It deals with the erection, assembly and the first commissioning of the<br />

BUFALO RONDOFIX.<br />

It is the operator's responsibility that everyone involved in the installation of the BUFALO<br />

RONDOFIX has read and understood these operating instructions.<br />

The following personnel and technical qualifications are required for erecting, assembling and<br />

commissioning the machine.<br />

6.1.1. Personnel, qualification<br />

The work described in this section may be carried out only by authorized skilled<br />

personnel who have had appropriate technical training and can draw upon the<br />

necessary experience, or who have been suitably instructed by the operator.<br />

6.1.2. Technical documentation<br />

This equipment may pose dangers if the safety rules are not<br />

followed. See Section 3: Security.<br />

The following technical documentation is needed for erecting, assembling and<br />

commissioning the machine:<br />

• electrical diagram<br />

This may be found in your technical documentation.<br />

6.1.3. Technical documentation<br />

The following technical documentation is needed for erecting, assembling and<br />

commissioning the machine:<br />

• electrical diagram<br />

This may be found in your technical documentation.<br />

� 38 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

6.2. Erecting and testing the machine<br />

Check the following points before commissioning:<br />

• Is the power cable intact and properly connected?<br />

Indication<br />

Check the rotation of the motors. The gluing rollers may be used for this. If<br />

they will not turn, the motor rotation needs reversing.<br />

• Has the power cable been laid covered and secured?<br />

• Are there no foreign materials on or at the machine'?<br />

• Check whether the paper grippers run properly and unobstructed.<br />

• Check whether the infeed station functions faultlessly and unobstructed.<br />

• Check whether the cutting station functions faultlessly and unobstructed.<br />

• Check whether the fixing station functions faultlessly and unobstructed.<br />

• Check whether the gluing station and gluing rollers function faultlessly and unobstructed.<br />

• Check whether the pressing station functions faultlessly and unobstructed.<br />

• Check whether the delivery station functions faultlessly and unobstructed.<br />

• If one of the stations malfunctions, see Section 7.6 Trouble Shooting and rectify the fault as<br />

instructed therein.<br />

6.2.1. Putting the machine into operation<br />

To commission the machine proceed as follows:<br />

• Schalten Sie den Hauptschalter ein.<br />

• Check the emergency stop switches and release them if necessary (see<br />

subsection 3.4).<br />

• Switch the machine on (see Section 5).<br />

• Switch the machine over to manual operation (see Section 7).<br />

• Test the door interlock circuit of the cutter/fixer and gluing station/press by opening<br />

the doors singly and closing them again. When any of these doors is opened the<br />

control must cut out and a fault must be signalled.<br />

6.2.2. Testing the function<br />

Check all functions according to Section 5 before considering the commissioning<br />

<strong>complete</strong>d and handing the machine over for normal operation.<br />

6.2.3. Acceptance certificate<br />

The acceptance certificate must be copied. Do not write on the original. See appendix.<br />

� 39 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

7. Operation<br />

Brief description: This section shows by means of example how the BUFALO<br />

RONDOFIX is operated. All routine steps for production are described in detail..<br />

7.1. Control Panel Description<br />

Fig. 22 Control Panel<br />

ALARM<br />

ESC<br />

SHIFT<br />

+1<br />

SYST<br />

MOD<br />

7.1.1. „Advance Reverse“ button<br />

Button for manual operation.<br />

-1<br />

� 40 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0<br />

SYST<br />

MENU<br />

ALARM<br />

ENTER<br />

DEL<br />

7<br />

8 9<br />

4 5 6<br />

1 2 3<br />

+/– 0 .<br />

Start<br />

MAGELiS<br />

Pressing this key makes the press stroke up as long as the key is pressed. If the cover<br />

is open it will function only if the dual-palm buttons on the press are pressed<br />

simultaneously.<br />

7.1.2. „Advance Forward“ button<br />

Button for manual operation.<br />

Press this button and keep it depressed to run the advance forwards. The<br />

speed selector must be set to minimum, otherwise an error message will<br />

appear.<br />

7.1.3. „Fixer Forward“ button“<br />

Button for manual operation.<br />

Press this button and keep it depressed to run the fixer forwards.<br />

Stop

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

7.1.4. „Fixer Reverse“ button<br />

Button for manual operation<br />

Button for manual operation.<br />

Press this button and keep it depressed to run the fixer in reverse.<br />

7.1.5. „Raise Press“ Button<br />

Button for manual operation.<br />

Press this button and keep it depressed to raise the press. If the glue unit safety cover<br />

is open, this button only functions if the "two-hand button" under this safety cover is<br />

pressed simultaneously.<br />

7.1.6. „Lower Press“ Button<br />

Button for manual operation.<br />

Press this button and keep it depressed to lower the press.<br />

7.1.7. „Insert Lining or Cover“ Button<br />

Button for all operational modes.<br />

Press this button to start the lining advance, or to insert a cover.<br />

7.1.8. „No Lining or Cover“ Button<br />

Button for semi and fully automatic operational modes.<br />

Press this button to stop the next lining advance, or to stop the insert of another cover.<br />

This function is automatically reset.<br />

When the function is active, the built-in diode in the button lights<br />

7.1.9. „Pusher“ Button<br />

Button for all operational modes.<br />

Press this button to actuate the pusher for a cycle. In semi and fully automatic<br />

operational modes, this button only functions when the machine is not operating.<br />

7.1.10. „Programme Input“ Button<br />

Press this button to enter programme input mode. This command is only<br />

accepted while the machine is not in operation. During programming the machine<br />

cannot be operated, neither in manual nor in an automatic mode.<br />

7.1.11. „Mode Type Select“ Button<br />

Press this button to select the operational mode type, between manual,<br />

semi and fully automatic operational modes.<br />

In manual operation mode, the milling cutter, fixer and glue unit can be switched on<br />

and off.<br />

In semi and fully automatic operational modes, only the desired programme number<br />

can be entered.<br />

� 41 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

7.1.12. „Start“ Button<br />

Button for all operational modes<br />

In semi and fully automatic operational modes, pressing this button starts the<br />

automatic cycle, or the semi-automatic cycle will be advanced one step.<br />

7.2. Switching On the Control System<br />

To put the machine into operation, first switch on the main switch on the control panel.<br />

Then actuate the control system by pressing the green luminous button. The control system is<br />

only active provided no emergency cut-off button has been pressed, and the milling cutter<br />

safety cover is closed. The emergency cut-off button can be disengaged by rotating it.<br />

The green luminous button lights when the control system is active.<br />

In cases of danger one of the emergency cut-off buttons must be pressed. After the<br />

malfunction has been eliminated, the pressed emergency cut-off button must be disengaged,<br />

and the open milling cutter cover closed, to allow the control system to be reactivated by<br />

pressing the green luminous button.<br />

When the main switch is engaged and the control system is not actuated, the blinking error<br />

message "No control voltage" appears on the control panel. This error message does not<br />

require any action at this point: it disappears automatically when the control system is<br />

actuated.<br />

Indication<br />

The first machine cycle must be made at minimum speed for operational<br />

reasons. Therefore, set the speed selector to minimum until the machine has<br />

<strong>complete</strong>d its first cycle. If this is forgotten, the machine will not carry out any<br />

forward advance, but instead the message "Set V-min" will be displayed. This<br />

error message does not require any action at this point: it disappears<br />

automatically when the start button, or the button which releases the forward<br />

advance, is released.<br />

If a forward advance is not <strong>complete</strong>d while in manual operation, the speed<br />

selector must be reset to minimum again.<br />

Indication<br />

After switching-on the control voltage the motors driving the various units are<br />

automatically started in staggered sequence.<br />

These drives are switched off automatically after running without load more<br />

than 5 minutes.<br />

The drives are switched on again automatically by operating a key or switch<br />

for manual or automatic operation.<br />

� 42 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

7.3. Operational Mode Selection<br />

After the main switch is engaged, the control system returns to the same operational mode in<br />

which it was before it was switched off.<br />

To change the operational mode, press the "Operational Mode Select" button. The<br />

following is displayed:<br />

Manual Semi Auto<br />

← ↓ →<br />

Select the desired operational mode by pressing the corresponding arrow key.<br />

7.3.1. Manual Operation<br />

After manual operational mode is selected (see above), the following is displayed:<br />

Milling Cutter ON 0<br />

The cutter can now be actuated by pressing the "MOD" button and then inputting 0 or<br />

1 (on or off). The input must be concluded by pressing "Enter", to advance the<br />

programme and the following is displayed:<br />

Fixer ON 0<br />

The fixer can now be switched on or off like the milling cutter.<br />

The display then displays the following:<br />

Glue heater<br />

Off ← On ↓ Auto →<br />

The glue heater can now be switched off in manual operational mode (cold gluing) or<br />

left on continuously, or switched on and off according to the timer programme.<br />

At the same time, the programme advances and displays:<br />

Tip Glue Unit<br />

The glue unit can be held in the desired position by pressing the manual button. If the<br />

manual button is held for more than 1 sec, the glue unit remains in position after the<br />

manual button is released. Pressing the manual button again restarts the glue unit<br />

Indication<br />

To stop the glue unit <strong>complete</strong>ly, use an emergency cut-off button.<br />

To exit this mode, press the "Enter" button. The following is now displayed:<br />

� 43 <strong>Operating</strong>s <strong>Instructions</strong> Edition 22. November 2007<br />

Bufalo Rondofix V3.0

<strong>Operating</strong> <strong>Instructions</strong><br />

BUFALO Rondofix V3.0<br />

Manual Operation<br />

In manual operation, all machine movements can be carried out individually and<br />

independently by pressing the corresponding buttons on the terminal.<br />

I no action is made for 5 minutes, the motors switch off automatically, and the machine<br />

goes into "Sleep mode". The following is displayed:<br />

Date XXXX<br />

Time XX.XX<br />

Before an action can be started, one of the function buttons must be pressed. This<br />

ends the "Sleep mode", and the motors restart automatically.<br />

7.3.2. Semi or Full Automatic Operation<br />

After selection of Semi of Full Automatic Operation (see above), the following is<br />

displayed:<br />

Progr. Number XXXX<br />

To enter the desired programme number, press the "MOD" button, type in the desired<br />

programme number, and confirm with "Enter". This loads the relative programme from<br />

the memory into the work register. Programme numbers must be numbers between 1<br />

and 20. An input of a programme outside this range will result in an error message,<br />

which must be exited by pressing "Enter", and the procedure repeated.<br />

The final step is to exit the "Select Operational Mode" function.<br />