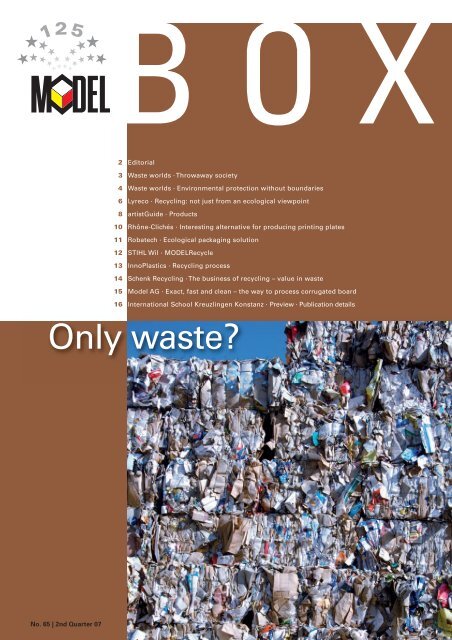

Only waste? - Model Holding AG

Only waste? - Model Holding AG

Only waste? - Model Holding AG

- TAGS

- www.modelgroup.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

No. 65 | 2nd Quarter 07<br />

BOX<br />

2<br />

3<br />

4<br />

6<br />

8<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

Editorial<br />

Waste worlds · Throwaway society<br />

Waste worlds · Environmental protection without boundaries<br />

Lyreco · Recycling: not just from an ecological viewpoint<br />

artistGuide · Products<br />

Rhône-Clichés · Interesting alternative for producing printing plates<br />

Robatech · Ecological packaging solution<br />

STIHL Wil · MODELRecycle<br />

InnoPlastics · Recycling process<br />

Schenk Recycling · The business of recycling – value in <strong>waste</strong><br />

<strong>Model</strong> <strong>AG</strong> · Exact, fast and clean – the way to process corrugated board<br />

International School Kreuzlingen Konstanz · Preview · Publication details<br />

<strong>Only</strong> <strong>waste</strong>?

EDITORIAL<br />

2<br />

Valuable <strong>waste</strong>?<br />

Almost all the goods we consume end up as<br />

<strong>waste</strong>. Precisely for this reason, western consumer<br />

societies with their huge consumption<br />

of goods attach great importance to reliable,<br />

clean <strong>waste</strong> disposal.<br />

In this respect, Switzerland’ has a commendable<br />

record. Whereas in the 1980s and 1990s<br />

<strong>waste</strong> disposal was a major source of environmental<br />

pollution and a nuisance for many of<br />

our country’s inhabitants, since then Switzerland<br />

has made considerable progress. Although<br />

success in cutting consumption of raw<br />

materials by producing more efficient and<br />

longer-lasting goods is still the exception, government<br />

regulations have drastically reduced<br />

the concentration of harmful substances in<br />

many products. All plastics, for instance, now<br />

have to be cadmium-free.<br />

In the past 20 years the increase in the amount<br />

of <strong>waste</strong> produced has been contained by separate<br />

collection of different <strong>waste</strong> fractions.<br />

Alongside <strong>waste</strong> incineration, refuse separation<br />

is the second prong of Swiss <strong>waste</strong> management<br />

policy. Better recycling is another important<br />

measure to reduce environmental pollution;<br />

today considerably more raw materials are<br />

returned to the circular flow of goods and services.<br />

In Switzerland, the proportion of recycled<br />

<strong>waste</strong> from households and small-scale commercial<br />

operations and industry has risen from<br />

approx. 25% in 1988 to some 51% in 2005.<br />

Various factors are behind this success, including<br />

the provisions of the regulation concerning<br />

beverage containers, which threaten the introduction<br />

of a deposit on containers if minimum<br />

recycling quotas are not met. Other important<br />

factors were the introduction of voluntary collection<br />

and funding systems by business, e.g.<br />

for PET drinks bottles, cans and paper; information<br />

provided by communes, <strong>waste</strong> collection<br />

operators and business; and finally polluterbased<br />

financing, i.e. fees charged for collecting<br />

sacks of non-recyclable refuse. In the final<br />

analysis, this success depends on motivating<br />

all inhabitants to cooperate. Neighboring<br />

countries have different legal provisions, with<br />

the result that further fractions are collected<br />

separately. For instance, in contrast to statutes<br />

in neighboring countries, Swiss legislation<br />

does not solely target packaging: Switzerland<br />

does not have a general regulation governing<br />

packaging, nor is one planned. On the other<br />

hand, there are provisions that apply to specific<br />

packaging types and properties.<br />

As the quality of recyclable raw materials is<br />

currently good, they command good prices in<br />

the market for recovered materials. However,<br />

new product developments (e.g. new product<br />

labels with metal-containing semiconductor<br />

chips) can impair the quality of collected material<br />

and, in turn, upset a well-functioning system.<br />

This needs to be addressed. The aim<br />

should be to ensure that a large part of all<br />

<strong>waste</strong> flows back into the economy in the form<br />

of cleaned and sorted secondary raw materials.<br />

All of these recycling systems not only help to<br />

reduce environmental pollution – recycling often<br />

uses fewer resources than disposal and<br />

new production –, but recycling also is often<br />

considerably cheaper than disposing of <strong>waste</strong><br />

in <strong>waste</strong> incineration plants. At the same time,<br />

there is no need to recycle at all cost: «Waste<br />

should be recycled if this causes less environmental<br />

pollution than <strong>waste</strong> disposal and the<br />

corresponding new production. In addition, recycling<br />

needs to have a solid long-term economic<br />

basis.» (Mission statement of the Swiss<br />

Waste Management Industry 1986).<br />

The ban on the direct disposal of non-recoverable<br />

<strong>waste</strong> and the major improvements in<br />

<strong>waste</strong> incineration have significantly reduced<br />

environmental pollution. A modern <strong>waste</strong> incineration<br />

plant can energetically convert <strong>waste</strong><br />

into heat and power that can also be used in industrial<br />

processes in the vicinity. Waste recycling<br />

thus makes a key contribution to the sustainable<br />

use of resources. This is a sensible<br />

use of, in particular, refuse that contains compounds<br />

and contaminated and mixed <strong>waste</strong>.<br />

Furthermore, there are signs that the energetic<br />

potential of other non-recoverable fractions<br />

may soon be put to good use, especially the<br />

processing of green <strong>waste</strong>, garden trimmings<br />

and possibly wood chips to fuel. Now this<br />

would unexpectedly turn <strong>waste</strong> into a valuable<br />

asset.<br />

Dr. Hans-Peter Fahrni<br />

Federal Office for the Environment FOEN

Throwaway society<br />

The throwaway society is a phenomenon<br />

of the western industrialized countries.<br />

In economies of scarcity – as in<br />

the Third World – people re-use things<br />

over and over again out of necessity.<br />

On the other hand, one advantage of<br />

these economic conditions is the low<br />

level of <strong>waste</strong> accumulation.<br />

What do we mean by throwaway mentality?<br />

A non-sustainability-based attitude and the<br />

thoughtless disposal of litter (e.g. bottles, paper,<br />

beverage cans, etc.) in the environment, in<br />

the street or in green spaces immediately after<br />

completion of consumption.<br />

The throwaway mentality or throwaway society<br />

is underpinned by the production and consumption<br />

of increasing quantities of unnecessary,<br />

short-dated goods. Today, many high-quality<br />

and correspondingly expensive products<br />

(electronic devices being a case in point) are<br />

often also so designed that even minor defects<br />

cannot be repaired or at a cost out of all proportion<br />

to the price. Critical voices argue that the<br />

only purpose of this is to force the consumer<br />

to buy new equipment, which, in turn, produces<br />

unnecessary <strong>waste</strong>.<br />

In industrialized countries the term «refuse<br />

emergency» has entered the vocabulary. This<br />

does not describe a state of too much refuse,<br />

but the lack of places to dispose of some or all<br />

of it. It applies in particular to commercial<br />

<strong>waste</strong>. Meanwhile, in other parts of the world<br />

people are dealing with emergencies of a very<br />

different nature.<br />

Living from and with refuse<br />

For thousands of people rubbish tips such as<br />

Smoky Mountain in Manila in the Philippines<br />

are both home and a source of work and income.<br />

The inhabitants of Smoky Mountain, for<br />

instance, have in effect created functioning recycling<br />

programmes. They convert the «unwanted»<br />

<strong>waste</strong> into valuable income-generating<br />

materials. So why are the inhabitants being<br />

evacuated? In tropical countries, heavy rains<br />

regularly cause devastating landslides in rubbish<br />

tips. The rainwater also carries noxious<br />

and unsanitary substances. Moreover, the<br />

stench and fumes are injurious to the inhabitants’<br />

health. They suffer from respiratory problems,<br />

nausea, headaches and other complaints.<br />

National and international organizations<br />

are helping to draw up and implement cost-effective<br />

programmes. The goal is not only to<br />

produce less <strong>waste</strong>, but also to recycle it properly.<br />

However, the emphasis is on measures to<br />

help the inhabitants. Resettlement has deprived<br />

many of them of their source of income.<br />

Hence, they are being trained in the professional<br />

recovery of materials from <strong>waste</strong> as well<br />

as new possibilities of processing it. More than<br />

100 housewives process old newspapers and<br />

telephone books into tissues and accessories<br />

for sale in the Australian market. A line of fashionable<br />

clothing has also been established to<br />

generate additional jobs.<br />

WASTE WORLDS<br />

Even though older Smoky Mountains have<br />

been grassed over, the dangers associated<br />

with them have not yet been banished. New<br />

rubbish tips are being created. Better organization<br />

has attracted new «inhabitants». The human<br />

race continues to produce increasing<br />

quantities of <strong>waste</strong>. So, while mothers cultivate<br />

their vegetable patches on what are now<br />

«green mountains», their children play in the<br />

rainwater run-off – completely disregarding the<br />

dangers of waterborne diseases. (Source and<br />

illustrations: Asian Development Bank, Manila,<br />

Rita Festin)<br />

3

WASTE WORLDS<br />

4<br />

Environmental protection<br />

Environmental protection is a topic of<br />

discussion everywhere. However, it is<br />

not managed in the same way in all<br />

countries. The <strong>Model</strong> Group operates in<br />

various European countries and among<br />

even these there are differences. The<br />

current issue of <strong>Model</strong> Box highlights<br />

various perspectives. A short description<br />

of the situation in the Philippines<br />

will be found on Page 3. Rules and regulations<br />

are somewhat stricter in<br />

Switzerland. Particular attention is given<br />

to the refuse incineration plant in<br />

the Canton of Thurgau, as this is where<br />

the headquarters of the <strong>Model</strong> Group<br />

are located. The situation in Poland,<br />

where the problems are different again,<br />

offers another comparison.<br />

Thurgau <strong>waste</strong> incineration plant KVA<br />

Thurgau – the organization<br />

Environmental protection is a key element in<br />

the corporate culture of the KVA Thurgau Association.<br />

KVA Thurgau operates a business that<br />

is compliant with environmental legislation and<br />

regards itself as a competent, self-critical service<br />

provider in the field of environmental protection.<br />

KVA Thurgau has adopted selective<br />

measures to promote environmental aware-<br />

ness and reduce <strong>waste</strong> both within its catchment<br />

area and beyond. It employs a safe and<br />

environmentally compatible technology to dispose<br />

of residual materials. KVA Thurgau practises<br />

open dialogue to reinforce the trust of its<br />

member communes, the population, its employees<br />

and its partners.<br />

KVA Thurgau uses a quality and environmental<br />

management system to ensure that its operations<br />

are transparent at all times.<br />

The KVA Thurgau Association actively provides<br />

information and consulting to promote the<br />

avoidance, reduction and recycling of <strong>waste</strong> on<br />

the part of residential developments, commerce<br />

and industry. Unavoidable <strong>waste</strong> is collected<br />

and sorted professionally and recycled<br />

using an environmentally compatible technology<br />

and thermally disposed of and/or deposited<br />

in landfills. KVA Thurgau gives support<br />

to the member communes in all questions related<br />

to <strong>waste</strong> and coordinates the different activities<br />

among the communes and beyond the<br />

canton’s borders.<br />

Instrumental in achieving clean <strong>waste</strong> management,<br />

fifty employees work at the <strong>waste</strong> incinerator<br />

plant in Weinfelden, the RAZ Hefenhofen<br />

regional collection center and the landfills<br />

in Pfyn and Kehlhof.<br />

The Thurgau <strong>waste</strong> incineration plant entered<br />

into operation in 1997. In the good ten years<br />

since then it has provided a clean, thermal<br />

means of disposing of well over a million<br />

tonnes of <strong>waste</strong>.<br />

KVA Thurgau values Thurpapier’s<br />

competence in cardboard disposal<br />

For a number of years the KVA Thurgau Association<br />

has collaborated with Thurpapier, a <strong>Model</strong><br />

Group company, which recycles a large part of<br />

the recovered paper and cardboard <strong>waste</strong>.<br />

Dieter Nägeli, divisional head of KVA Thurgau is<br />

very satisfied: «Our cooperation functions perfectly.<br />

We are involved primarily in negotiating<br />

contracts and prices; operational matters are<br />

decided directly between the collecting partners<br />

and recyclers.»<br />

Outsourcing of recoverable paper<br />

collection<br />

In particular, local societies and schools top up<br />

their club or classroom funds by collecting<br />

<strong>waste</strong> paper and cardboard. Collection is coordinated<br />

directly with Texta <strong>AG</strong>, St. Gallen and<br />

deliveries are taken to Thurpapier. The residents<br />

of Thurgau collect some 3,600 tonnes of<br />

cardboard a year, equal to 19 kg per inhabitant.<br />

This requires well thought-out logistics. Thanks<br />

to years of cooperation, everything functions<br />

smoothly.<br />

KVA Thurgau also supplies Thurpapier fully with<br />

process steam in order to reduce the combustion<br />

of oil and gas. This results in an excellent<br />

CO2 balance.<br />

Collecting alone is not enough<br />

As Dieter Nägeli points out: «Previously, everything<br />

was <strong>waste</strong>; today it is clear that besides<br />

<strong>waste</strong> there are also recyclable materials and<br />

raw materials. As raw materials are used up,<br />

the importance of recycling is growing». As a<br />

producer of recycling articles, Thurpapier plays<br />

a big part in ensuring that the products obtained<br />

from <strong>waste</strong> are recycled for consumption.<br />

However, consumers also have to shoulder<br />

responsibility: «The cycle only functions if<br />

end users consciously buy and use as many recycled<br />

products as possible.» In other words,<br />

every one of us is called upon to make a personal<br />

contribution to environmental protection.

without boundaries<br />

Waste management in Poland<br />

Waste management policy in Poland is regulated<br />

by Polish and EU law. In other words,<br />

all EU regulations have legal force in Poland.<br />

Of the many guidelines and statutes, those<br />

relating to the following areas are the most<br />

important:<br />

1. The country’s <strong>waste</strong> management industry<br />

2. Recycling of used cars that have been dis -<br />

posed of<br />

3. Electronic goods and household appliances<br />

4. Packaging and recoverable packaging<br />

5. Waste management law<br />

6. Manufacturer’s obligation (including, among<br />

other things, product and landfill charges)<br />

7. Environmental protection<br />

8. Cleanliness in communes (the smallest,<br />

most immediate level of self-government)<br />

From 2009 onwards, in all countries (with the<br />

exception of Poland, Cyprus and Malta) the<br />

content of recycled material in packaging must<br />

be at least 55%.<br />

A selection of regulations in Poland<br />

In most cases, Poland has adapted its national<br />

ordinances to those of the EU. However,<br />

Poland has, for instance, been given a grace<br />

period until 2014 to introduce stricter regulations<br />

governing the recycling of packaging.<br />

At present, packaging has about 25% recycled<br />

content; this is forecast to rise to 36.6% in<br />

2007.<br />

Poles have to separate <strong>waste</strong>. Residents of the<br />

country are obliged to dispose of glass, metal,<br />

plastic, paper (all in segregated bags) and biological<br />

<strong>waste</strong> separately. Furthermore, all citizens<br />

have to take used consumer-goods batteries<br />

to collection points or return them to<br />

dealers or manufacturers. In certain sectors different<br />

principles of <strong>waste</strong> management apply,<br />

e.g. medicine, electronic appliances, hazardous<br />

materials, excrement, chemicals, etc.<br />

Used cars are an enormous problem. What<br />

should be done with cars that are no longer<br />

roadworthy? To date Poland has imported<br />

some two million very old cars. To impose<br />

some order, all outlets that sell more than 1000<br />

cars a year are obliged to scrap the used cars.<br />

Otherwise they have to pay a fee of about 130<br />

euros per car. The scrapping facility may not be<br />

more than 50 km from the car owner’s registered<br />

address. Facilities responsible for scrapping<br />

or breaking up cars have to recycle 85%<br />

of the car by weight, otherwise they, too, have<br />

to pay fees.<br />

Quantities of <strong>waste</strong> in Poland in 2004<br />

(in million tonnes)<br />

Total 11.802<br />

Biological <strong>waste</strong> 2.486<br />

Paper and cardboard 2.114<br />

Plastic 1.529<br />

Glass 0.889<br />

Metal 1.521<br />

Forecast quantities of <strong>waste</strong> (in million t):<br />

2014: 12.290<br />

2018: 12.962<br />

Forecast for recycling in 2007:<br />

paper and cardboard 48% (highest level)<br />

glass 40%<br />

plastic 25%<br />

Quantities of recycling in Poland in 2006<br />

compared to the EU (in million tonnes)<br />

Actual Minimum quantities<br />

quantities for recycling according<br />

2006 to the EU (in 2008)<br />

Plastic 0.070 0.1627<br />

Paper and cardboard 0.825 0.9763<br />

Glass 0.400 0.6686<br />

Based on the national regulation on <strong>waste</strong><br />

treatment<br />

5 million tonnes<br />

4<br />

3<br />

2<br />

1<br />

0<br />

1985 1990 1995 2000 2005<br />

WASTE WORLDS<br />

Quantities of <strong>waste</strong> in Switzerland in 2005<br />

(in million tonnes)<br />

Total 15.671<br />

Building <strong>waste</strong> 11.9<br />

Residential <strong>waste</strong> 4.99<br />

of which recycled: 2.41<br />

<strong>waste</strong> paper 1.24<br />

glass 0.3<br />

electrical and electronic<br />

appliances 0.0825<br />

PET bottles 0.0316<br />

Incinerated <strong>waste</strong> 3.14<br />

Incineration capacity of <strong>waste</strong> incineration<br />

plants 2005: 3.377<br />

Situation in Switzerland<br />

Recycling quotas:<br />

Glass: 96%<br />

Paper and cardboard: about 77%<br />

PET beverage bottles > 75%<br />

Total residential <strong>waste</strong> in Switzerland in 2005: 4.94 million tonnes<br />

Development in collection of separated <strong>waste</strong> and of residential <strong>waste</strong> (source: BAFU 2007)<br />

Sep. coll. 51%<br />

2.5 m t<br />

335 kg/inhab.<br />

■ Div. recycling<br />

■ Glass<br />

■ Paper<br />

■ Compost<br />

■ Residential <strong>waste</strong><br />

(2.44 m t, 327 kg/inhab.)<br />

5

LYRECO<br />

6<br />

Recycling: not just from<br />

Interview with Erwin Fries, Logistics<br />

Director, Lyreco Switzerland<br />

Founded in 1926, Lyreco <strong>AG</strong> is a B2B<br />

office supplies company with 11,000<br />

employees worldwide. The former<br />

Büro-Fürrer <strong>AG</strong> company has been part<br />

of the Lyreco Group since 2005. Its 400<br />

employees in Switzerland generate annual<br />

sales of more than CHF 162 million.<br />

Lyreco is principally concerned<br />

with bundling the flow of goods so as<br />

to simplify the purchasing of corporate<br />

office supply materials.<br />

In Switzerland, Lyreco <strong>AG</strong> operates under two<br />

brands: for office and coffee supplies under<br />

the Lyreco label, and office furniture under the<br />

Büro-Fürrer label. The company’s clientele is<br />

drawn from across the business spectrum in<br />

Switzerland. Both small firms and large companies<br />

such as UBS order goods from Lyreco. Today,<br />

online orders account for 70% of Lyreco’s<br />

sales. This corresponds to a volume of about<br />

4000 packages a day that are sent all over<br />

Switzerland. To ensure a smooth delivery service,<br />

Lyreco has to have reliable partners and<br />

suppliers – in respect not only of delivery<br />

times, but also of quality and price. Although<br />

certification still plays a subordinate role in our<br />

industry, it is becoming an increasingly prominent<br />

factor.<br />

Customers that place their orders by 5 pm will<br />

have their goods delivered personally by a<br />

driver on the next business day. To make this<br />

happen, more than 110 employees work different<br />

function-based shifts in logistics between<br />

5 am and, as a rule, about 7 pm. The logistics<br />

department divides the day into two shifts:<br />

the blue shift and the red shift.<br />

Blue shift (inbound process)<br />

In the morning the conveyor belt is used to<br />

move new supplies of goods to the storage<br />

area. Merchandise is delivered, controlled and<br />

recorded at an early hour. Then it is placed in<br />

blue-labelled reusable packaging and transported<br />

by conveyor belt to the appropriate<br />

warehousing zones for storage. This simple<br />

procedure ensures that the potential of the<br />

packaging line is optimally exploited and the<br />

«traffic volumes» of the forklift drivers are kept<br />

to a minimum.<br />

Red shift (outbound process)<br />

This afternoon shift deals with customer orders.<br />

Orders are either recorded in the central<br />

SAP ERP system or automatically integrated<br />

from the online shop and then forwarded to<br />

distribution centre control. The first step is to<br />

calculate the volume of the order and assign<br />

the correct packaging to it, which is marked<br />

red. The empty packaging in different sizes is<br />

automatically delivered by conveyor belt to the<br />

various packing stations where the corresponding<br />

articles have been sent by a paperless<br />

procedure. The final step in the packaging line<br />

is quality control. After that, the deliveries are<br />

loaded onto SBB rail wagons, which transport<br />

them to the four hubs in Switzerland (Geneva,<br />

Berne, Ticino and St.Gallen) or directly to the<br />

drivers for local distribution in the region<br />

Zurich, Aargau, Basel and Lucerne. The packages<br />

arrive at their destinations early in the<br />

morning, where they are sorted and delivered<br />

directly to customers by a fleet of trucks.<br />

Empty Lyreco packaging put out by customers<br />

is picked up by the drivers and taken back to<br />

the distribution centres. This combined railand-road<br />

concept has proved to be an optimal<br />

solution, and one that also makes a valuable<br />

contribution to environmental protection.<br />

Where did the idea of using reusable<br />

packaging come from?<br />

Lyreco has always proactively tried to translate<br />

customer needs into performance. In recent<br />

years it has become apparent that customers<br />

have grown more aware of ecological issues.<br />

Customers would also like to cut down on superfluous<br />

material. The choice of five packaging<br />

sizes meets this need. Reusable cartons<br />

also obviate the need for additional packaging<br />

for return and sample consignments. The customer<br />

simply places the returns in the reusable<br />

packaging. Approx. 50% of all dispatch packaging<br />

is sent back with our drivers and more than<br />

30% can be reused in the packaging process.

Cardboard pre-cuts<br />

produced<br />

an ecological viewpoint<br />

Raw materials<br />

procured<br />

Pre-cuts<br />

stored<br />

Waste cardboard<br />

recycled<br />

Materials required<br />

delivered to Lyreco<br />

Reusable box<br />

fed back into<br />

recycling process<br />

<strong>Model</strong>/Lyreco reusable boxes: ecological cycles<br />

Lyreco’s environmental commitment<br />

In addition to reusable packaging and the general<br />

distribution using SBB (Cargo), Lyreco took<br />

other steps to protect the environment. For instance,<br />

empty toner and inkjet cartridges, batteries,<br />

etc. can be returned free of charge for<br />

proper disposal. All <strong>waste</strong> that is collected or<br />

produced is sorted and then professionally disposed<br />

of. The product catalogue of more than<br />

480 pages is printed on 100% recycled paper.<br />

Partners as well as employees are encouraged<br />

to actively participate in this kind of environmental<br />

protection. Lyreco in Switzerland is<br />

currently working towards certification to<br />

ISO 14001.<br />

Reusable boxes<br />

returned<br />

Reusable box<br />

produced/assembled<br />

Order delivered<br />

to Lyreco’s<br />

end customer<br />

Customer order<br />

picked &<br />

prepared<br />

What about your employees? What can<br />

they expect from you?<br />

Lyreco has signed on to the Global Compact.<br />

This lays down clear principles in respect of<br />

human rights, social labour standards, environmental<br />

protection and combating corruption.<br />

These principles are regularly reiterated to<br />

employees and actively practised.<br />

Will the company need the services of a<br />

distribution centre in the future as well?<br />

Owing to the spread of globalization, internationally<br />

active customers have a growing interest<br />

in negotiating single buyer contracts for<br />

their worldwide operations. The better in-<br />

LYRECO<br />

formed we are about our customers’ needs,<br />

the better we can advise them and harmonize<br />

volumes and prices on a global basis. Certification<br />

to ISO 9001 and 14001 will further increase<br />

demands on suppliers and logistics.<br />

It remains an exciting market that is bound to<br />

offer a lot in the way of new challenges that<br />

call for new solutions.<br />

7

ARTISTGUIDE<br />

Hengstenberg Bio Display<br />

The Hengstenberg range of organic products<br />

was launched last year. Whether in bags, jars<br />

or displays, the items have a unifying, instantly<br />

recognizable label. This display presents the<br />

entire 12-product Biolinie range in a clear, wellstructured<br />

arrangement in supermarkets and<br />

department stores.<br />

Frucht-Tiger<br />

This Frucht-Tiger (fruit tiger) offers children a<br />

way to quench their thirst. The tiger surrounded<br />

by fruit is an important element of this<br />

packaging. The tiger is flexo printed on the exterior<br />

of the packaging.<br />

The thirst quencher comes in three different<br />

flavors. After opening the package, the consumer<br />

has no problem selecting his choice of<br />

flavor. This solution also has distinct advantages<br />

for dealers. It can, for instance, be transported<br />

without difficulty. At the same time, it<br />

functions as a counter display.<br />

8<br />

Products<br />

Modifast<br />

Slim is the message of<br />

this flexible solution for<br />

Modifast bottles. The<br />

laminated offset<br />

printed display has a<br />

modular construction consisting<br />

of individual trays, a base and a<br />

crowner.<br />

The individual trays are placed directly on the<br />

counter in pharmacies and drugstores. Or the<br />

base can be placed on the floor and the trays<br />

mounted on top to create an attractive, freestanding<br />

display.<br />

Wine boxes for Martel<br />

Martel, a client, required an exclusive-looking,<br />

yet robust wine packaging. A uniform design<br />

has been created for the colorful boxes with inserts<br />

for 6, 3, 2 or 1 bottle. The exterior surface<br />

is printed in two-colored offset design and subsequently<br />

laminated. The interior has a flexoprinted<br />

surface. Delivered as flat packs, the<br />

packaging is quickly converted into practical<br />

boxes that are simple to open and shut.<br />

Marlboro Travelbox<br />

Working in close cooperation with <strong>Model</strong>,<br />

Philip Morris created this distinguished packaging<br />

for «Marlboro», the most popular cigarette<br />

brand in the world. Each Travelbox is printed in<br />

red, green and gold and holds ten packets of<br />

cigarettes. Travelboxes are produced exclusively<br />

for sale in duty-free shops.<br />

The outer box is specially glued. On opening<br />

this covered packaging you discover an ingenious<br />

insert and a partition strip that ensure optimal<br />

presentation of the product. Embossing<br />

and UV gloss elegantly highlights the Marlboro<br />

logo. Hot-foil printing is used to tastefully<br />

heighten the contrast with the UV matt finish<br />

of the printed outer box.<br />

Put an end to insects<br />

In many places insects are a<br />

real pest. This counter-top display<br />

has been specially developed<br />

for the German market.<br />

Thanks to the dispenser base,<br />

the display is easy to set up. A<br />

cover placed over the display<br />

protects the «Clean Kill» set<br />

so that it can be easily transported.<br />

An eye-grabbing<br />

crowner catches shoppers’<br />

attention at the point of sale.<br />

Spritzer<br />

Still looking for a light, superior quality,<br />

palatable, low-alcohol drink for that special<br />

occasion? Each of these<br />

small bottles is filled with<br />

27.5 cl of Rimuss to satisfy<br />

the taste of the discriminating<br />

individual.<br />

The distinctive gold-andsilver<br />

design of the fivecolor<br />

flexoprinted pack<br />

containing 12 bottles<br />

has an eye-catching appeal.<br />

The printing is fully lacquered for protection.<br />

In addition to the bottles, Rimuss has introduced<br />

drinks in cans. To attract the attention of<br />

the beverage trade to this new product, the<br />

manufacturer has distributed an amusing<br />

gift pack that contains not only a can of<br />

beverage, but also a glass and a straw.<br />

Thanks to its form, content and offset<br />

laminated printing, this very elegant<br />

packaging has triggered a positive market<br />

reaction.

sia soft<br />

The packaging is intended<br />

to mirror the high-quality finish<br />

of this high-end abrasive<br />

from sia. The once<br />

brown outer wrapping has<br />

been enhanced technically as well as<br />

qualitatively. The emotional element of the design<br />

is consciously heightened. Since sia soft<br />

is used primarily in the automotive industry, the<br />

aim is to transfer people’s emotional bond with<br />

cars to this product. The clear varnish finishings<br />

show a beautiful packaging to superb<br />

advantage.<br />

The Association of Lucerne Carpenters<br />

and Joiners<br />

The Association of Lucerne Carpenters and<br />

Joiners intends to present something special at<br />

the Lucerne Trade Fair. Usually visitors stick<br />

their prospectuses in their rucksacks; this year<br />

the Association wanted an alternative means<br />

of carriage. One condition is that the<br />

customers should spend more time<br />

at the Association's stand. In addition,<br />

the giveaway article should be<br />

durable and attract attention. At the<br />

same time, the visitors should come<br />

into contact with the principal material<br />

of carpentry: wood.<br />

The result is the trolleybox, a combination<br />

of corrugated board<br />

and wood. It is not so<br />

easy to leave with a<br />

trolley as one might<br />

think; it first has to be<br />

assembled. Curiosity<br />

and the positive response<br />

of visitors have even led to<br />

waiting times at the stand.<br />

Afterwards, the trolley<br />

makes a useful container<br />

for a variety of things, for<br />

instance around the house or in a<br />

child’s room, or to distribute mail.<br />

Music stool<br />

Gifts for musicians. Music lovers will find<br />

socks, cups, erasers and other ideas for gifts at<br />

the Kübler music boutique. But there is one<br />

thing they won’t find: musical instruments.<br />

Designed especially for Kübler, the music stool<br />

can be used for decorative purposes by music<br />

stores, or to provide seating at<br />

trade fairs. And of course it can<br />

also be used as a practice stool.<br />

Thanks to its prominent motif,<br />

this idea has high advertising<br />

appeal and strikes a chord with<br />

the defined target group.<br />

HotWheels<br />

Children’s eyes light up<br />

when they catch sight of this<br />

fast racetrack. This attractive display,<br />

which <strong>Model</strong> designed is an extremely<br />

short space of time, was produced for an<br />

Easter sales campaign. The display was placed<br />

at the POS in Carrefour and Coop stores all<br />

over Switzerland. Various <strong>Model</strong> businesses<br />

were closely involved in this project. The exterior<br />

sections are litholaminated offset printed.<br />

The display was constructed in Weinfelden<br />

and assembled and stocked with the supplied<br />

products in-house.<br />

Haco Mirador display<br />

You don’t only need spices in<br />

the barbecue season. This<br />

multi-section display presents<br />

Mirador spices in luminous<br />

yellow. <strong>Model</strong> assembles<br />

and fills the ready-touse<br />

display and delivers it<br />

direct to the regional Migros<br />

warehouse. A litholaminated<br />

offset printed crowner is an<br />

additional eye-catcher.<br />

Haco Subito rice<br />

display<br />

Consumers need to be able<br />

to get these tasty<br />

rice dishes<br />

off the<br />

shelves just as<br />

fast as they can prepare<br />

them. The open display<br />

solution meets this requirement.<br />

And the additional<br />

support construction<br />

also allows for problem-free<br />

transportation.<br />

ARTISTGUIDE<br />

Toblerone display –<br />

winner of the 2006<br />

WORLDSTAR<br />

After receiving a Swiss<br />

Star last year, the Toblerone<br />

display has now<br />

capped this performance<br />

with a WorldStar.<br />

For its display Kraft Foods<br />

was looking for a solution<br />

that would allow<br />

the existing shelf trays<br />

to function as display<br />

shelves as well. In the solution<br />

developed the trays are suspended in<br />

a column at an angle so that they slant forwards.<br />

Thanks to the tilt, customers have a<br />

clear view of the entire contents and can<br />

easily extract the Toblerone triangles. The<br />

well-designed arrangement provides space<br />

for 60 400g Toblerone bars. Being on a slant,<br />

the contents automatically slide forward<br />

each time a Toblerone is removed.<br />

Every customer immediately associates the<br />

triangular display column with the famous<br />

Toblerone shape.<br />

The <strong>Model</strong> designers of the display were<br />

proud to accept the WorldStar award in May.<br />

9

RHÔNE-CLICHÉS<br />

Interesting alternative for<br />

producing printing plates<br />

10<br />

Talking to<br />

Frédéric Valz-Blin<br />

Rhône-Clichés has analyzed<br />

all of its customer<br />

orders for the corrugated<br />

board industry<br />

for a year. This study<br />

determined the percent<br />

fraction of <strong>waste</strong> for<br />

printing plates of solid<br />

photopolymer plastics.<br />

The manufacturer has<br />

searched for new methods<br />

for further development<br />

of the production<br />

process in order to<br />

shorten their production<br />

times.<br />

In parallel with this study,<br />

Rhône-Clichés requested<br />

their customers from the<br />

corrugated board processing<br />

sector to rethink and redefine<br />

their requirements for<br />

plates and their production.<br />

As a result, corrugated board<br />

processing has demanded<br />

an especially cost-effective<br />

plate which should be<br />

specifically adapted to the<br />

individual orders.<br />

Quality should satisfy the<br />

special requirements for<br />

printing corrugated board.<br />

The fact that qualitative<br />

losses in print will not be<br />

accepted in the various<br />

processes (in-line, die-cutting,<br />

off-line presses) goes without saying.<br />

The study demonstrated that those responsible<br />

for printing in the corrugated board industry<br />

expect the following of the printing plates:<br />

Plates should also enable optimum color<br />

transfer to a print substrate consisting primarily<br />

of recycled material.<br />

The plate material must be compressible<br />

enough to also smooth out or lessen the unevenness<br />

and the washboard effect in the<br />

corrugated board.<br />

Plates must be easy to mount and easy to<br />

handle.<br />

The plate material should ideally be workable<br />

in various Shore hardnesses for halftone and<br />

large-format printing on a plate.<br />

In specific cases, printing plates without adhesive<br />

films or sealing of the plate material<br />

on both sides are requested. In compact<br />

assembly, the liquid photopolymer is poured<br />

directly on the Mylar film.<br />

Goals: removal of the photopolymer material<br />

from the Mylar film and prevention of water<br />

penetrating between the film and plate<br />

material.<br />

Possibility of high-quality printing of the corrugated<br />

board without crushing its height due<br />

to the printing pressure and support pressure.<br />

An express production process, in case of<br />

misprints on the printing press.<br />

High stability.<br />

We have performed studies together with our<br />

customers, also including <strong>Model</strong> Emballages,<br />

and have decided on the production of plates<br />

from the newest generation of liquid photopolymer.<br />

We will then equip these plates<br />

with all of the technical refinements.<br />

What are the technical advantages of liquid<br />

photopolymer?<br />

The most important quality advantages of the<br />

liquid photopolymer are reasonable costs, flexible<br />

production, good print quality and high environmental<br />

compatibility.<br />

Why have you decided on this possibility?<br />

We are firmly convinced that this is an interesting<br />

alternative which can optimally fulfill the<br />

needs of the corrugated board market.<br />

Economic advantages:<br />

Plates are already available after 60 minutes<br />

instead of 180 minutes.<br />

98% of the unexposed liquid photopolymer<br />

can be recycled.<br />

Ecological advantages:<br />

The liquid solvents which were used in prod -<br />

ucing the conventional plates from solid printing<br />

plates are replaced here with a simple<br />

soap solution. This is thus a long-term investment<br />

in environmental protection, ensuring<br />

compliance with the ISO-14000 standard.<br />

Why don't all plate manufacturers resort to<br />

this technology?<br />

Because it requires considerable finances,<br />

90% of which are eliminated in the corrugated<br />

board sector and which have no benefit for<br />

printing soft polyethylene packaging (plastic<br />

bags, films, etc.) – this is thus a realignment in<br />

development strategy. For us, this liquid<br />

process only supplements the engraving lines<br />

which work with solid photopolymer plates<br />

(traditional and digital method). In addition, it<br />

has not yet been possible to run high-definition<br />

four-color print jobs in Masterflex with this procedure,<br />

although tests with somewhat more<br />

viscous materials are currently running in this<br />

area.<br />

How does the printing plate manufacturing<br />

process work with liquid photopolymers?<br />

A Distribution module: phase 1<br />

1. Preparation: the negative film is placed on a<br />

glass plate and is protected with a light dis -<br />

posable film. Now a layer of the liquid photopolymer<br />

can be applied – simultaneously<br />

with the «film substrate».<br />

2. Exposure: rear and front exposure. In liquid<br />

photopolymers technology, the UV light<br />

sources from above provide for rear exposure,<br />

and the light sources from below provide<br />

for front exposure. All of the transparent<br />

negative parts transmit the UV light and<br />

cure the exposed polymers. The unexposed<br />

areas remain liquid and can be recycled.<br />

B Engraving module: phase 2<br />

Following exposure, all processing proceeds in<br />

the engraving module. The procedure can be<br />

subdivided in 3 steps:<br />

1. Recovery of unexposed polymers: the protective<br />

film is removed and the uncured liquid<br />

polymers are removed with hot compressed<br />

air. This enables recycling of up to<br />

98% of the unused material. Using solid<br />

printing plates, the material in the uncured<br />

areas would have been lost. The liquid<br />

photopolymer recovered in this way is returned<br />

to the «main tank» and can be recycled<br />

up to 100%.<br />

2. Washing out: the last residual liquid is<br />

washed out with soap water (concentration:<br />

approx. 2%).<br />

3. Surface treatment: irradiation with UVC and<br />

UVA completely eliminates the «tacky» surface.<br />

The plate can now be further processed.<br />

Production time: 60 minutes.<br />

Tests and development are ongoing. The continuing<br />

development of new technologies is<br />

highly important to meet both ecological as<br />

well as economic and technical requirements.

Ecological<br />

packaging solution<br />

Interview with Loan Kutter, Marketing<br />

Assistant, and Ruedi Brun, Marketing<br />

Head.<br />

Robatech, a Swiss family-owned enterprise,<br />

is one of the world’s largest<br />

manufacturers of gluing application<br />

equipment and systems. The Robatech<br />

Group operates in more than 38 countries<br />

and has vast experience in the<br />

application of adhesives and sealants.<br />

What is so special about Robatech<br />

equipment?<br />

The machines we produce in our own factories<br />

are always tailored to the customer’s needs.<br />

They all produce an excellent performance. Regardless<br />

of the manufacturing date and the unit<br />

model, the components of the individual machines<br />

are mutually compatible. Customers are<br />

trained to use new machines. Once a customer<br />

knows how to use our units, very little<br />

training is needed for other machines, as the<br />

programming and maintenance is very similar<br />

for all our equipment.<br />

At the start of the process, we make a point of<br />

consulting intensively with our customers in<br />

our experimental laboratory. This enables us to<br />

evaluate the customer’s requirements and, together<br />

with the customer, test different approaches<br />

to solutions on the spot.<br />

How important is packaging for your<br />

machines?<br />

The common characteristic of all our products<br />

is high quality. Thanks to our global network,<br />

these are sent all over the world, which is why<br />

it is of fundamental importance that we can<br />

rely on the equipment reaching the recipient in<br />

perfect condition. In addition, we also have to<br />

be cost-efficient in our use of packaging.<br />

Tell us about your packaging system?<br />

Instead of using environmentally harmful filling<br />

material, our packaging solutions are made exclusively<br />

of corrugated board. It took a lot of<br />

time and effort on the part of <strong>Model</strong> to develop<br />

the current – very satisfactory – solution. The<br />

core element of the packaging is its ingenious<br />

base. It locks the machines in position on the<br />

floor and guarantees that the machines arrive<br />

in perfect condition. Empty spaces are filled<br />

with small boxes that also serve as packaging<br />

for auxiliary material. The stable base and lid<br />

sections are sized to fit europallets, which enables<br />

us to stack several boxes of machinery<br />

on top of one another for transport. The packages<br />

are so stable that our partners can re-use<br />

them without any difficulty to forward items to<br />

the end-user.<br />

It simplifies matters that we sat down with<br />

<strong>Model</strong> and standardized packaging sizes. Thus,<br />

although we need different base inserts for the<br />

various machines and components, it is only<br />

one base and one top section for each packaging.<br />

<strong>Model</strong> helped us to optimize our warehouse.<br />

What do you look for in your partners?<br />

Our partners have to be recognized within their<br />

own industry and customer-oriented. We attach<br />

importance to cost-effectiveness in the industrial<br />

process. To achieve the targets we<br />

have set ourselves we depend on our partners,<br />

because our machines only function if the raw<br />

materials are absolutely free of defects.<br />

Another not insignificant factor is the ratio between<br />

price and performance. In addition, we<br />

have to keep the logistics of integrating the<br />

raw materials delivered to us simple. To<br />

achieve this, we use the so-called Kanban system<br />

in our dealings with our suppliers.<br />

(Editor’s remark: see<br />

<strong>Model</strong> Box 61)<br />

What contribution<br />

can you make in a<br />

time of scarce raw<br />

materials?<br />

The Robatech company<br />

develops entire<br />

systems for the application<br />

of adhesives.<br />

ROBATECH<br />

Of course, we are an interesting partner for our<br />

customers only inasmuch as we develop units<br />

and application nozzles that use less glue to<br />

achieve the same adhesive strength. For this,<br />

however, we depend on the research and development<br />

of adhesive manufacturers. And in<br />

the final instance, our customers will prefer our<br />

systems only if they give them an extra advantage.<br />

Unfortunately, even ecological solutions have<br />

to be cost-effective, otherwise they cannot be<br />

implemented without strict state control. Increased<br />

substitution of closed nozzle systems<br />

for rollers can reduce adhesive application<br />

weights, which also saves energy and space<br />

when the machine is not in use.<br />

Your products are used in packaging,<br />

printing and graphics, woodworking, car<br />

manufacturing and the textile and hygiene<br />

industries. What do you have to watch out<br />

for in particular with each specific appli -<br />

cation of adhesives?<br />

Materials, the properties of the adhesive, and<br />

the process speeds differ from industry to industry<br />

and application to application. Thanks to<br />

the extensive practical experience of our application<br />

technicians, we can adapt standard solutions<br />

to individual situations.<br />

How do you see the future development in<br />

your market?<br />

Innovation is the key to Robatech’s ambitions<br />

to become a market leader and new products<br />

are the key to active growth in new niches. On<br />

the other hand, we are also steadily gaining<br />

market share in our traditional markets such as<br />

packaging. The Swiss market in particular is<br />

very aware of «total cost of ownership (TCO)»,<br />

i.e. overall cost effectiveness. Thanks to highquality<br />

reliable products, we have a reputation<br />

for operational safety and low maintenance<br />

costs. We believe that in the medium term<br />

these factors will also play a more significant<br />

role in low-wage countries.<br />

11

Recycling process<br />

As a consequence of the <strong>Model</strong><br />

Group’s decision to hive off its plastics<br />

recycling business, Martin <strong>Model</strong>’s<br />

Inno <strong>Holding</strong> <strong>AG</strong> and the Texta Group<br />

in Eschlikon together founded Inno -<br />

Recycling <strong>AG</strong> and InnoPlastics <strong>AG</strong> to<br />

acquire the plastics recycling operations<br />

of Poly Recycling <strong>AG</strong>.<br />

InnoRecycling collects<br />

and separates <strong>waste</strong><br />

and forwards the fractions<br />

to the appropriate<br />

recycling companies.<br />

Thurpapier receives<br />

recoverable<br />

paper and cardboard<br />

and InnoPlastics, an<br />

affiliated company,<br />

the soiled polyethylene.<br />

This company<br />

processes the plastic<br />

to granulates, which are used to manufacture<br />

new products. Plastics recycling is a young industry<br />

with huge potential, and as the price of<br />

oil needed to make plastics continues to rise,<br />

recycling makes increasing economic and ecological<br />

sense. Not surprisingly, the two companies<br />

have developed splendidly.<br />

Martin <strong>Model</strong> himself runs InnoPlastics with<br />

enormous personal commitment and pioneering<br />

spirit. We wanted to learn from him how<br />

the plastics recycling market functions and to<br />

what extent there are similarities with the recoverable<br />

paper processing operations of Thurpapier,<br />

a <strong>Model</strong> Group company. As one might<br />

guess from his name, Martin <strong>Model</strong> is well<br />

acquainted with both procedures.<br />

Are there any obvious similarities between<br />

the <strong>Model</strong> Group and InnoPlastics?<br />

Both companies offer solutions that make ecological<br />

sense: products made from <strong>waste</strong> materials,<br />

which conserves resources. InnoPlastics<br />

produces plastic granulates and the <strong>Model</strong><br />

Group papers that are subsequently processed<br />

into corrugated board. Supplies of raw materials<br />

are guaranteed, as these are<br />

produced from local <strong>waste</strong> ma-<br />

➊<br />

terials and not imported<br />

from or transported<br />

➏<br />

through areas of political<br />

conflict. This groundbreaking<br />

local closed<br />

loop led major customers<br />

such as Denner<br />

to outsource its ➎<br />

entire <strong>waste</strong> disposal<br />

to InnoRecycling.<br />

➍<br />

Do the collection and recycling processes<br />

at Thurpapier function like those at<br />

InnoPlastics?<br />

Both InnoPlastics and Thurpapier close the<br />

recycling loop, thus offering their clients an<br />

ingenious solution that will become more<br />

important in the future.<br />

The sources of recovered plastics and cardboard<br />

<strong>waste</strong> are often the same – for example,<br />

distribution centres.<br />

However, there are considerable differences in<br />

processing, although the technical challenges<br />

are similar, whether it be fluctuations in raw<br />

material quality, high wastage on account of<br />

the contaminated raw materials, or the enormous<br />

costs in the field of <strong>waste</strong> water.<br />

Typically, both companies are also subject to<br />

hefty market volatility, in recent years most<br />

particularly in the huge increases in the costs<br />

of raw materials and rising prices.<br />

Thanks to its higher collection quota and welldeveloped<br />

market for recoverable materials,<br />

Thurpapier has a greater range of raw materials<br />

to choose from. The collection quotas for plastics<br />

are still too small, although the potential is<br />

huge. The possibilities of employing recovered<br />

plastics are far from exhausted. Recycled<br />

plastics can, for instance, also be used as an<br />

alternative fuel.<br />

Both recyclers offer their customers important<br />

advantages, logistical as well as ecological:<br />

supplies on the outward journey, <strong>waste</strong> disposal<br />

on the return – their raw material can always<br />

be transported on the return journey, the<br />

so-called empty run. This reduces transport<br />

costs.<br />

Is the market situation for recycling processes<br />

in Switzerland similar to that abroad?<br />

Switzerland promotes <strong>waste</strong> incineration.<br />

Other countries favor recycling. However, high<br />

➋<br />

➌<br />

How the plastic recycling process<br />

works<br />

➊ Deliveries<br />

➋ Cut up<br />

➌ Wash<br />

➍ Separate<br />

➎ Granulate<br />

➏ Use<br />

INNOPLASTICS<br />

commodity prices have helped to improve the<br />

market situation. At present, <strong>waste</strong> incineration<br />

plants obtain sufficient refuse from abroad, and<br />

collecting recoverable materials pays because<br />

of high commodity prices.<br />

Trends in the recycling business<br />

Rising raw material prices and scarce resources<br />

in conjunction with environmental<br />

policy are bound to translate into increases in<br />

collection quotas and demand for recycling.<br />

There are signs of a growing investment boom<br />

which will make its mark in the market.<br />

Precisely because plastics recycling is a young<br />

industry, reliability – not only in delivery times,<br />

but also in quality – is a significant factor in<br />

guaranteeing the firms’ survival. The same<br />

optimized technology, deep experience and<br />

processing know-how have triggered greater<br />

demand for InnoPlastics’ granulates from<br />

abroad as well. Today, InnoPlastics exports<br />

around 40% of its production volume to neighboring<br />

countries. Italy is one of the most<br />

important markets.<br />

The plastics recycling market remains exciting<br />

since there are as yet no «off-the-peg» machines<br />

and today you still have to lend a<br />

hand and tinker with every single processing<br />

machine.<br />

13

SCHENK RECYCLING<br />

The business of recycling –<br />

value in <strong>waste</strong><br />

Karl Schenk founded his company in<br />

Albstadt Laufen (State of Baden Württemberg)<br />

some 50 years ago. It started<br />

off by recycling recovered paper using<br />

a single mechanical baling press. By<br />

1980, the firm had grown so big that it<br />

had to move into new premises. Still a<br />

family business, Schenk Recycling is<br />

now headed by Ute Schenk. The company<br />

specializes in collecting, transporting<br />

and sorting materials.<br />

Schenk Recycling accepts various recyclable<br />

materials, including paper, film, loose polystyrene,<br />

wood and certain related products<br />

such as belts, canisters and edge protection<br />

made of paper. The materials are collected in<br />

different ways in containers of varying sizes.<br />

A number of large companies collect recoverable<br />

material in containers and press containers<br />

located on their premises. Schenk sends its<br />

own trucks to pick these up as soon as they<br />

are full. Smaller containers have been set up in<br />

a number of different places (in particular<br />

schools and other public buildings) and are<br />

picked up on a regular timetable. Some of the<br />

<strong>waste</strong> material is delivered directly to the gates<br />

of Schenk Recycling. Regardless of how the<br />

goods are delivered, on arrival in Balingen they<br />

are checked by the receiving office. Pre-sorted<br />

materials are placed directly on the conveyor<br />

belt and pressed into bales in the channel baling<br />

press; most of the <strong>waste</strong> materials, however,<br />

need to be sorted. This is done in two<br />

sorting plants, in which the employees sort the<br />

14<br />

material by hand in accordance with specific<br />

criteria. Then these materials are also pressed<br />

or loaded as loose material into containers. The<br />

bales are stored separately by quality and material<br />

and sold. <strong>Only</strong> sorted material is valuable.<br />

People who think that recycling is an easy business<br />

are very much mistaken. A study of the<br />

stringent statutory specifications for the industry<br />

is enough to open people's eyes. Although<br />

the regulations deal primarily with <strong>waste</strong> products,<br />

the entire process is subject to strict legal<br />

provisions. Schenk works exclusively with nonhazardous<br />

materials, as hazardous materials<br />

are subject to even stricter regulations. Besides<br />

the obvious material-related provisions,<br />

there are also a number of statutory regulations<br />

governing in-house operations. In many<br />

cases, skills and licenses apply to people and<br />

not the firm, so that these frequently have to<br />

be renewed when the personnel changes.<br />

The recycling process turns the «<strong>waste</strong><br />

product» into a valuable commodity<br />

This is Ute Schenk’s starting point. She has<br />

had herself certified as a <strong>waste</strong> disposal specialist<br />

and has adapted the company’s<br />

processes accordingly. The trend towards using<br />

recycling materials is growing. The market<br />

for recoverable paper has grown 40-fold in the<br />

past 50 years. Although environmental awareness<br />

suffered a brief setback, it is on the rise<br />

again. Demand for recycled materials is huge,<br />

with the result that prices in the industry are<br />

very volatile. Schenk’s size gives it a crucial<br />

market advantage. The company is now a constant<br />

in the recycling landscape. It is in a posi-<br />

tion to react flexibly and quickly to its customers’<br />

needs, be they paper factories, <strong>waste</strong><br />

material merchants, recyclers, or service<br />

providers. The prices are based on the price<br />

level calculated by the business information<br />

service EUWID Recycling and Waste Management.<br />

Trends<br />

As a consequence of the sustained high consumption<br />

of recoverable paper by the European<br />

paper and cardboard industry, there are<br />

signs of growing competition for supplies of<br />

the secondary raw material, recoverable paper.<br />

The marginal increase in quantities of recoverable<br />

paper in some European states is unlikely<br />

to substantially alter this situation.<br />

(Source: Recy Aktuell, No. 3)

Exact, fast and clean<br />

Exact, fast and clean – the way to<br />

process corrugated board<br />

Thanks to just-in-time deliveries and putting<br />

production directly on rail or road instead of<br />

warehousing it, the size of orders is falling<br />

steadily. In particular the food industry, one of<br />

the largest consumers of corrugated board<br />

packaging, demands a large number of different,<br />

often very small, top-grade printed, highprecision<br />

processed forms of packaging.<br />

To ensure that people, machines and material<br />

work together better and so enhance productivity,<br />

<strong>Model</strong> also invests in in-house logistics,<br />

including solutions to collect and recycle diecutting<br />

<strong>waste</strong> as economically and ecologically<br />

as possible.<br />

A case in point is the Weinfelden site, which<br />

this year installed a new corrugated board disposal<br />

system incorporating state-of-the-art<br />

technology. Recoverable corrugated board was<br />

previously shredded by hand, now it is tossed<br />

directly onto a conveyor belt by a machine. It is<br />

then pressed into bales and forwarded directly<br />

into the in-house recycling loop (Thurpapier)<br />

(see also the InnoPlastics interview on Page 13<br />

of this issue of <strong>Model</strong> Box).<br />

The recycling of this material, whether corrugated<br />

board or paper, creates a lot of dust. Until<br />

recently, this was sucked out through an exhaust<br />

ventilation system. Now it is collected in<br />

a piping system, pressed into briquettes and<br />

removed. This protects not only the employees’<br />

respiratory tracts, but also reduces wear<br />

and tear of the control system and mechanics<br />

of the converters. Less dust also has a positive<br />

effect on the printing quality of the packaging<br />

involved.<br />

The adapted dust extraction plant and the new<br />

<strong>waste</strong> disposal system have resulted not only<br />

in «cleaner» jobs, but also a «smooth» conversion.<br />

The removal of the shredder and the ventilator<br />

has also noticeably reduced dust and<br />

noise emissions. Of course, this is also a response<br />

to the company’s successful BRC/IoP<br />

hygiene certification in summer 2005.<br />

Corrugated board continued to be manufactured<br />

and processed throughout the remodeling<br />

phase. This required an enormous logistical<br />

effort. It was necessary to suspend production<br />

for five days to install the last components and<br />

complete the project. The transition from the<br />

old to the new in-house recycling system<br />

demonstrates how good communication can<br />

smooth the process of remodeling.<br />

MODEL <strong>AG</strong><br />

15

PREVIEW<br />

16<br />

International School Kreuzlingen Konstanz<br />

The International School at Kreuzlingen, Konstanz (ISKK) opened its doors in August 2004.<br />

The ISKK is open to children and young people in the 3 to 11 age group from all over the world. The<br />

splendid learning environment of the Villa Doldenhof, a family atmosphere with a day-school structure,<br />

an English-language environment in which children easily develop fluency, an environment<br />

that permits and encourages independent learning, a respectful attitude towards one another and<br />

the theme-oriented preparation of the subject matter, internationalism and much more besides are<br />

just a few of the attributes that apply to the school.<br />

The school is based on the principle of the «Haus des Lernens». One of the things we mean by this<br />

is the opportunity for everybody to take responsibility to the full extent of his possibilities. Depending<br />

on the age group, children undertake more profound, more far-reaching projects. The day-school<br />

system encourages the child to take responsibility in the personal sense, as well as for his school<br />

work. Solutions to conflicts, whether personal or school-related, are worked out jointly with the<br />

children. This is an active contribution to the children’s development.<br />

The ISKK is open to children who do not yet have a command of English. The qualifications<br />

awarded are recognized nationally and internationally, so that children can transfer from the stateschool<br />

system to the ISKK and vice versa without difficulty.<br />

The ISKK International School at Kreuzlingen, Konstanz is run by a charitable foundation. The<br />

operating company is SBW «Haus des Lernens», a private school in Romanshorn.<br />

Most of the ISKK’s funding comes from school fees and business. Children whose parents lack the<br />

necessary financial resources should also be given a chance to enrol. To this end, places are<br />

sponsored by companies.<br />

The <strong>Model</strong> company promotes and supports projects that foster a sense of responsibility in children<br />

and young people. This is why it has decided to make a financial contribution to the ISKK.<br />

Both towns – Konstanz and Kreuzlingen – supported the project because it would appeal to further<br />

international circles and contribute to the attractions of the location.<br />

Many thanks to our interview partners:<br />

Federal Office for the Environment FOEN, Dr. Hans-Peter Fahrni, www.umwelt-schweiz.ch<br />

KVA Thurgau, Dieter Nägeli, www.kvatg.ch<br />

Lyreco <strong>AG</strong>, Erwin Fries, www.lyreco.ch<br />

Rhône-Clichés, Médialliance Groupe, Frédéric Valz-Blin, www.medialliance.org<br />

Robatech <strong>AG</strong>, Loan Kutter and Ruedi Brun, www.robatech.ch<br />

STIHL & Co., Peter Weibel, Antoine D'Aversa and Stefan Benz, www.stihl-co.ch<br />

InnoPlastics, Martin <strong>Model</strong>, www.innoplastics.ch<br />

Schenk Recycling, Ute Schenk<br />

Asian Development Bank, Rita Festin, www.adb.org/phco<br />

ISKK, Stefan Preisig, www.iskk.ch<br />

<strong>Model</strong> Box<br />

The <strong>Model</strong> Group customer magazine<br />

Volume 18, published quarterly<br />

© <strong>Model</strong> Management <strong>AG</strong>, 2007<br />

www.modelgroup.com<br />

Circulation<br />

3900 copies German, 1800 copies French, 400 copies English<br />

Editors<br />

Luis Flores, Editor-in-Chief, luis.flores@modelgroup.com<br />

Karin Bächer, karin.baecher@modelgroup.com<br />

Ruth Wiesmann, Editorial Assistant, ruth.wiesmann@modelgroup.com<br />

<strong>Model</strong> Management <strong>AG</strong>, T +41 (0) 71 626 76 21<br />

Layout<br />

dfp Kommunikation <strong>AG</strong>, Weinfelden<br />

Printing<br />

heer druck ag, Sulgen<br />

The cover of the current issue was printed on Thurpapier Testliner III 130 g/m 2 , the contents on Sihl Eika RecyStar 100 g/m 2