GASPARDO Seminatrici SpA - Opico

GASPARDO Seminatrici SpA - Opico

GASPARDO Seminatrici SpA - Opico

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

52<br />

ENGLISH<br />

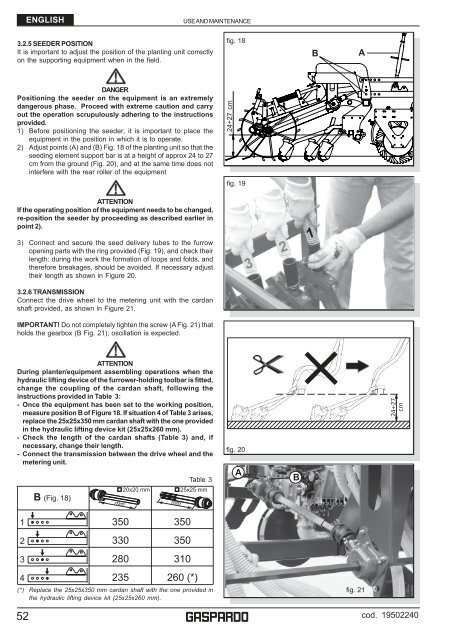

3.2.5 SEEDER POSITION<br />

It is important to adjust the position of the planting unit correctly<br />

on the supporting equipment when in the field.<br />

DANGER<br />

Positioning the seeder on the equipment is an extremely<br />

dangerous phase. Proceed with extreme caution and carry<br />

out the operation scrupulously adhering to the instructions<br />

provided.<br />

1) Before positioning the seeder, it is important to place the<br />

equipment in the position in which it is to operate.<br />

2) Adjust points (A) and (B) Fig. 18 of the planting unit so that the<br />

seeding element support bar is at a height of approx 24 to 27<br />

cm from the ground (Fig. 20), and at the same time does not<br />

interfere with the rear roller of the equipment<br />

ATTENTION<br />

If the operating position of the equipment needs to be changed,<br />

re-position the seeder by proceeding as described earlier in<br />

point 2).<br />

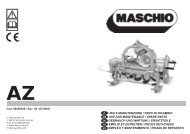

3) Connect and secure the seed delivery tubes to the furrow<br />

opening parts with the ring provided (Fig. 19), and check their<br />

length: during the work the formation of loops and folds, and<br />

therefore breakages, should be avoided. If necessary adjust<br />

their length as shown in Figure 20.<br />

3.2.6 TRANSMISSION<br />

Connect the drive wheel to the metering unit with the cardan<br />

shaft provided, as shown in Figure 21.<br />

IMPORTANT! Do not completely tighten the screw (A Fig. 21) that<br />

holds the gearbox (B Fig. 21); oscillation is expected.<br />

ATTENTION<br />

During planter/equipment assembling operations when the<br />

hydraulic lifting device of the furrower-holding toolbar is fitted,<br />

change the coupling of the cardan shaft, following the<br />

instructions provided in Table 3:<br />

- Once the equipment has been set to the working position,<br />

measure position B of Figure 18. If situation 4 of Table 3 arises,<br />

replace the 25x25x350 mm cardan shaft with the one provided<br />

in the hydraulic lifting device kit (25x25x260 mm).<br />

- Check the length of the cardan shafts (Table 3) and, if<br />

necessary, change their length.<br />

- Connect the transmission between the drive wheel and the<br />

metering unit.<br />

1<br />

2<br />

3<br />

4<br />

B (Fig. 18)<br />

350<br />

330<br />

280<br />

235<br />

Table 3<br />

20x20 mm 25x25 mm<br />

USE AND MAINTENANCE<br />

350<br />

350<br />

310<br />

260 (*)<br />

(*) Replace the 25x25x350 mm cardan shaft with the one provided in<br />

the hydraulic lifting device kit (25x25x260 mm).<br />

fig. 18<br />

24÷27 cm<br />

fig. 19<br />

fig. 20<br />

g<br />

B<br />

12345678901234567890123456789012123456789012345<br />

12345678901234567890123456789012123456789012345<br />

12345678901234567890123456789012123456789012345<br />

A<br />

B<br />

A<br />

fig. 21<br />

24÷27<br />

cm<br />

cod. 19502240