GASPARDO Seminatrici SpA - Opico

GASPARDO Seminatrici SpA - Opico

GASPARDO Seminatrici SpA - Opico

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

56<br />

ENGLISH<br />

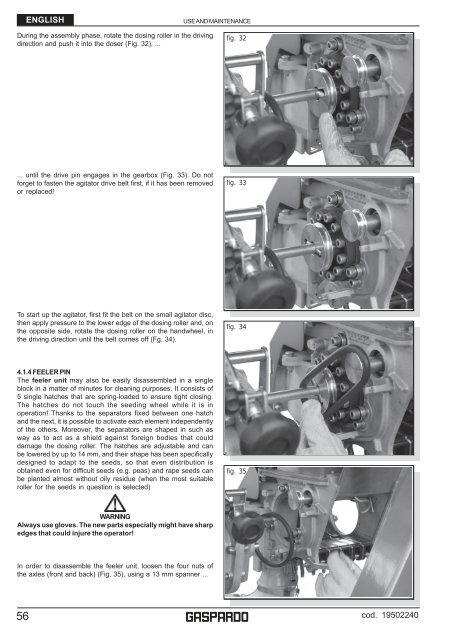

During the assembly phase, rotate the dosing roller in the driving<br />

direction and push it into the doser (Fig. 32), ...<br />

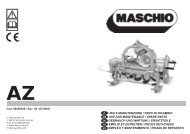

... until the drive pin engages in the gearbox (Fig. 33). Do not<br />

forget to fasten the agitator drive belt first, if it has been removed<br />

or replaced!<br />

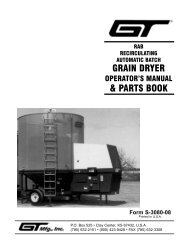

To start up the agitator, first fit the belt on the small agitator disc,<br />

then apply pressure to the lower edge of the dosing roller and, on<br />

the opposite side, rotate the dosing roller on the handwheel, in<br />

the driving direction until the belt comes off (Fg. 34).<br />

4.1.4 FEELER PIN<br />

The feeler unit may also be easily disassembled in a single<br />

block in a matter of minutes for cleaning purposes. It consists of<br />

5 single hatches that are spring-loaded to ensure tight closing.<br />

The hatches do not touch the seeding wheel while it is in<br />

operation! Thanks to the separators fixed between one hatch<br />

and the next, it is possible to activate each element independently<br />

of the others. Moreover, the separators are shaped in such as<br />

way as to act as a shield against foreign bodies that could<br />

damage the dosing roller. The hatches are adjustable and can<br />

be lowered by up to 14 mm, and their shape has been specifically<br />

designed to adapt to the seeds, so that even distribution is<br />

obtained even for difficult seeds (e.g. peas) and rape seeds can<br />

be planted almost without oily residue (when the most suitable<br />

roller for the seeds in question is selected)<br />

WARNING<br />

Always use gloves. The new parts especially might have sharp<br />

edges that could injure the operator!<br />

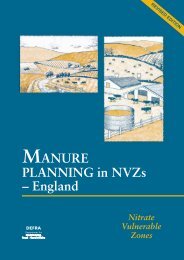

In order to disassemble the feeler unit, loosen the four nuts of<br />

the axles (front and back) (Fig. 35), using a 13 mm spanner ...<br />

USE AND MAINTENANCE<br />

fig. 32<br />

fig. 33<br />

fig. 34<br />

fig. 35<br />

g<br />

cod. 19502240