GASPARDO Seminatrici SpA - Opico

GASPARDO Seminatrici SpA - Opico

GASPARDO Seminatrici SpA - Opico

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

62<br />

ENGLISH<br />

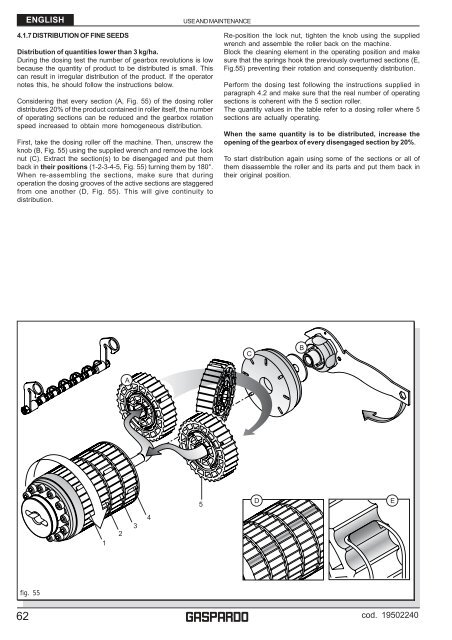

4.1.7 DISTRIBUTION OF FINE SEEDS<br />

Distribution of quantities lower than 3 kg/ha.<br />

During the dosing test the number of gearbox revolutions is low<br />

because the quantity of product to be distributed is small. This<br />

can result in irregular distribution of the product. If the operator<br />

notes this, he should follow the instructions below.<br />

Considering that every section (A, Fig. 55) of the dosing roller<br />

distributes 20% of the product contained in roller itself, the number<br />

of operating sections can be reduced and the gearbox rotation<br />

speed increased to obtain more homogeneous distribution.<br />

First, take the dosing roller off the machine. Then, unscrew the<br />

knob (B, Fig. 55) using the supplied wrench and remove the lock<br />

nut (C). Extract the section(s) to be disengaged and put them<br />

back in their positions (1-2-3-4-5, Fig. 55) turning them by 180°.<br />

When re-assembling the sections, make sure that during<br />

operation the dosing grooves of the active sections are staggered<br />

from one another (D, Fig. 55). This will give continuity to<br />

distribution.<br />

fig. 55<br />

1<br />

2<br />

A<br />

3<br />

4<br />

USE AND MAINTENANCE<br />

5<br />

g<br />

Re-position the lock nut, tighten the knob using the supplied<br />

wrench and assemble the roller back on the machine.<br />

Block the cleaning element in the operating position and make<br />

sure that the springs hook the previously overturned sections (E,<br />

Fig.55) preventing their rotation and consequently distribution.<br />

Perform the dosing test following the instructions supplied in<br />

paragraph 4.2 and make sure that the real number of operating<br />

sections is coherent with the 5 section roller.<br />

The quantity values in the table refer to a dosing roller where 5<br />

sections are actually operating.<br />

When the same quantity is to be distributed, increase the<br />

opening of the gearbox of every disengaged section by 20%.<br />

To start distribution again using some of the sections or all of<br />

them disassemble the roller and its parts and put them back in<br />

their original position.<br />

C<br />

D<br />

B<br />

E<br />

cod. 19502240