Beverage & Packaging Division - Sacmi

Beverage & Packaging Division - Sacmi

Beverage & Packaging Division - Sacmi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

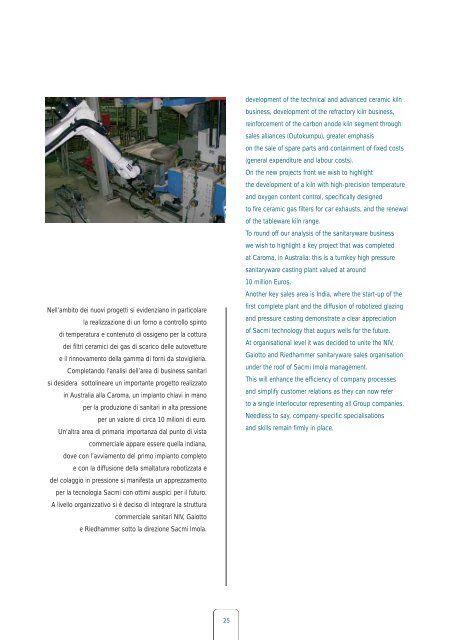

Nell’ambito dei nuovi progetti si evidenziano in particolare<br />

la realizzazione di un forno a controllo spinto<br />

di temperatura e contenuto di ossigeno per la cottura<br />

dei filtri ceramici dei gas di scarico delle autovetture<br />

e il rinnovamento della gamma di forni da stoviglieria.<br />

Completando l’analisi dell’area di business sanitari<br />

si desidera sottolineare un importante progetto realizzato<br />

in Australia alla Caroma, un impianto chiavi in mano<br />

per la produzione di sanitari in alta pressione<br />

per un valore di circa 10 milioni di euro.<br />

Un’altra area di primaria importanza dal punto di vista<br />

commerciale appare essere quella indiana,<br />

dove con l’avviamento del primo impianto completo<br />

e con la diffusione della smaltatura robotizzata e<br />

del colaggio in pressione si manifesta un apprezzamento<br />

per la tecnologia <strong>Sacmi</strong> con ottimi auspici per il futuro.<br />

A livello organizzativo si è deciso di integrare la struttura<br />

commerciale sanitari NIV, Gaiotto<br />

e Riedhammer sotto la direzione <strong>Sacmi</strong> Imola.<br />

25<br />

development of the technical and advanced ceramic kiln<br />

business, development of the refractory kiln business,<br />

reinforcement of the carbon anode kiln segment through<br />

sales alliances (Outokumpu), greater emphasis<br />

on the sale of spare parts and containment of fixed costs<br />

(general expenditure and labour costs).<br />

On the new projects front we wish to highlight<br />

the development of a kiln with high-precision temperature<br />

and oxygen content control, specifically designed<br />

to fire ceramic gas filters for car exhausts, and the renewal<br />

of the tableware kiln range.<br />

To round off our analysis of the sanitaryware business<br />

we wish to highlight a key project that was completed<br />

at Caroma, in Australia: this is a turnkey high pressure<br />

sanitaryware casting plant valued at around<br />

10 million Euros.<br />

Another key sales area is India, where the start-up of the<br />

first complete plant and the diffusion of robotized glazing<br />

and pressure casting demonstrate a clear appreciation<br />

of <strong>Sacmi</strong> technology that augurs wells for the future.<br />

At organisational level it was decided to unite the NIV,<br />

Gaiotto and Riedhammer sanitaryware sales organisation<br />

under the roof of <strong>Sacmi</strong> Imola management.<br />

This will enhance the efficiency of company processes<br />

and simplify customer relations as they can now refer<br />

to a single interlocutor representing all Group companies.<br />

Needless to say, company-specific specialisations<br />

and skills remain firmly in place.