Beverage & Packaging Division - Sacmi

Beverage & Packaging Division - Sacmi

Beverage & Packaging Division - Sacmi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

27<br />

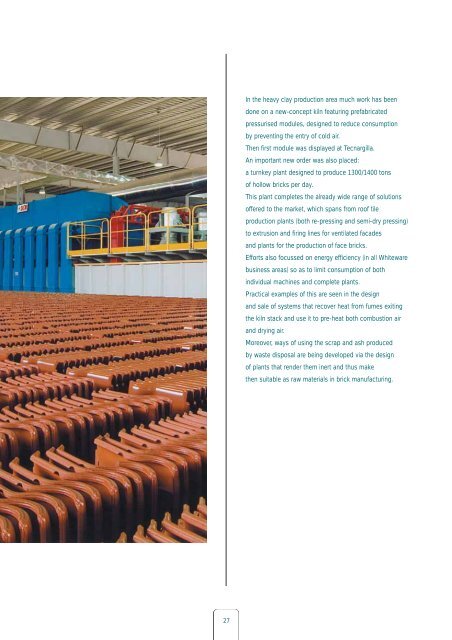

In the heavy clay production area much work has been<br />

done on a new-concept kiln featuring prefabricated<br />

pressurised modules, designed to reduce consumption<br />

by preventing the entry of cold air.<br />

Then first module was displayed at Tecnargilla.<br />

An important new order was also placed:<br />

a turnkey plant designed to produce 1300/1400 tons<br />

of hollow bricks per day.<br />

This plant completes the already wide range of solutions<br />

offered to the market, which spans from roof tile<br />

production plants (both re-pressing and semi-dry pressing)<br />

to extrusion and firing lines for ventilated facades<br />

and plants for the production of face bricks.<br />

Efforts also focussed on energy efficiency (in all Whiteware<br />

business areas) so as to limit consumption of both<br />

individual machines and complete plants.<br />

Practical examples of this are seen in the design<br />

and sale of systems that recover heat from fumes exiting<br />

the kiln stack and use it to pre-heat both combustion air<br />

and drying air.<br />

Moreover, ways of using the scrap and ash produced<br />

by waste disposal are being developed via the design<br />

of plants that render them inert and thus make<br />

then suitable as raw materials in brick manufacturing.