istruzioni di installazione e uso calandre mcm use and ... - IMESA SpA

istruzioni di installazione e uso calandre mcm use and ... - IMESA SpA

istruzioni di installazione e uso calandre mcm use and ... - IMESA SpA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

E071001X 12/10/07<br />

The surface where the machine is position must bear at least 500 kg/m 2 : the machine load can be<br />

considered static. The machine must be positioned in a good aired room (as per the normative in force) <strong>and</strong><br />

the room temperature must be between +10°C <strong>and</strong> +35°C.<br />

In the room must be granted an air recycle proportional to the air <strong>use</strong>d by the machine.<br />

The ironer must be vented <strong>di</strong>rectly from outside in an environment free from pollution. The ventilation must<br />

be guaranteed by permanent opening on the room walls, which are looking on outside. The net free total<br />

section must comply with local rules on matter.<br />

7. EXHAUST AND HUMID AIR CONDUCTION<br />

The exhaust conduction (for gas heated ironer) must comply with the rule on matter in force. In case of gas<br />

heated ironer the chimney must be adequately far from easily inflammable or combustible materials (at least<br />

500 mm). Contact with this material must be avoided using air space or insulators. In case the <strong>di</strong>stance<br />

cannot be respected, please <strong>use</strong> an adequate protection against heat.<br />

The exhaust conduction can be 15 mt long (<strong>di</strong>ameter 100 mm) <strong>and</strong> must be insulated or pre<strong>di</strong>sposed in a<br />

way to collect the eventual condenses. In case the length need to be more than 15 mt the installer must<br />

contact the manufacturer.<br />

The exhaust conduction, the connection to the chimney flue <strong>and</strong> the chimney flue must be realized<br />

complying with national <strong>and</strong> local rules in force. Use of rigid ducts is compulsory; connections between<br />

elements must be tight <strong>and</strong> all the elements must be resistant to heat, condenses <strong>and</strong> mechanical<br />

solicitation.<br />

Chimney flue not adequately <strong>di</strong>mensioned or not correctly shaped amplifies burning noises <strong>and</strong> gives<br />

condenses problems; they may alter burning parameter making easier soot <strong>and</strong> scales. In order to avoid<br />

burned gas exit <strong>and</strong> noise, connections must be tight; <strong>use</strong> material (filler, rubber solution, silicones) heat<br />

resistant.<br />

The <strong>use</strong>r must be well aware <strong>and</strong> trained about the dangerousness connected with the<br />

tumping with conductions <strong>and</strong>/or mo<strong>di</strong>fication, obstructions or ructions about the installation<br />

room ventilation openings.<br />

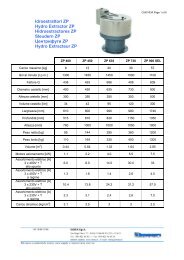

Refer to the here attached technical data sheet for <strong>di</strong>mensions <strong>and</strong> quote about gas <strong>and</strong> humid air exhaust.<br />

8. ELECTRIC CONNECTION<br />

Electric connection must be carried out by qualified technicians <strong>and</strong> must comply with local <strong>and</strong> national<br />

rules in force.<br />

Check the supply tension, it must comply with the label data on the ironer back. To connect the machine,<br />

please <strong>use</strong> a cable H05 VV – F or more. The cable must be <strong>di</strong>mensioned following the here below section<br />

chart:<br />

2500 2800 3200<br />

Electric heating 5x25mm 2 5x25mm 2 5x25mm 2<br />

Steam/gas heating 3x2,5mm 2 3x2,5mm 2 3x2,5mm 2<br />

Before the ironer power supply line install a device for <strong>di</strong>sconnection (i.e.: magnetothermal <strong>di</strong>fferential unit)<br />

with a contact opening which allows the complete <strong>di</strong>sconnection in case of the con<strong>di</strong>tions of III category over<br />

tension are verified, complying with the rules in force.<br />

Be sure the main switch is in position “0”.<br />

Open the side door using the key given with the ironer documents.<br />

Take off the door.<br />

Pass the cable through the cable holder on the ironer left side.<br />

Electric supply must be done connecting the cable to the terminals mounted on the ironer:<br />

Ξ: ground<br />

L1, L2, L3: phase<br />

N: neutral<br />

36