istruzioni di installazione e uso calandre mcm use and ... - IMESA SpA

istruzioni di installazione e uso calandre mcm use and ... - IMESA SpA

istruzioni di installazione e uso calandre mcm use and ... - IMESA SpA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

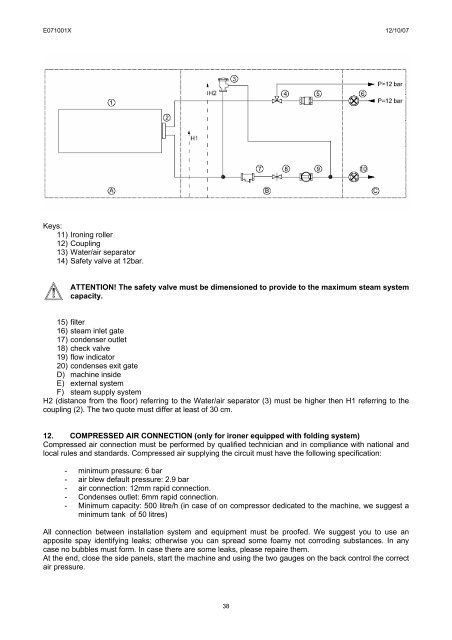

E071001X 12/10/07<br />

Keys:<br />

11) Ironing roller<br />

12) Coupling<br />

13) Water/air separator<br />

14) Safety valve at 12bar.<br />

ATTENTION! The safety valve must be <strong>di</strong>mensioned to provide to the maximum steam system<br />

capacity.<br />

15) filter<br />

16) steam inlet gate<br />

17) condenser outlet<br />

18) check valve<br />

19) flow in<strong>di</strong>cator<br />

20) condenses exit gate<br />

D) machine inside<br />

E) external system<br />

F) steam supply system<br />

H2 (<strong>di</strong>stance from the floor) referring to the Water/air separator (3) must be higher then H1 referring to the<br />

coupling (2). The two quote must <strong>di</strong>ffer at least of 30 cm.<br />

12. COMPRESSED AIR CONNECTION (only for ironer equipped with fol<strong>di</strong>ng system)<br />

Compressed air connection must be performed by qualified technician <strong>and</strong> in compliance with national <strong>and</strong><br />

local rules <strong>and</strong> st<strong>and</strong>ards. Compressed air supplying the circuit must have the following specification:<br />

- minimum pressure: 6 bar<br />

- air blew default pressure: 2.9 bar<br />

- air connection: 12mm rapid connection.<br />

- Condenses outlet: 6mm rapid connection.<br />

- Minimum capacity: 500 litre/h (in case of on compressor de<strong>di</strong>cated to the machine, we suggest a<br />

minimum tank of 50 litres)<br />

All connection between installation system <strong>and</strong> equipment must be proofed. We suggest you to <strong>use</strong> an<br />

apposite spay identifying leaks; otherwise you can spread some foamy not corro<strong>di</strong>ng substances. In any<br />

case no bubbles must form. In case there are some leaks, please repaire them.<br />

At the end, close the side panels, start the machine <strong>and</strong> using the two gauges on the back control the correct<br />

air pressure.<br />

38