2023-09 SUSTAINABLE BUS

A new issue of Sustainable Bus is out today. In this upcoming edition, we’ve curated a diverse and comprehensive range of topics that spotlight the latest developments in the world of sustainable mobility. From cutting-edge technological advancements to market insights and industry transformations, this issue promises to be a captivating exploration of the future of public transportation. What you could fine inside? Well, a market insight will offer you a detailed look at the European e-bus market, providing you with a comprehensive understanding of the mid-2023 results. The leading e-bus market in Europe is still UK: therefore, we focused our attention on that specific market with a report that sums up strategies, focus, goals of the most prominent industry players. A technology spotlight on the delicate topic of batteries, authored by Claudius Jehle, look at battery management and strategies to ensure the smooth and cost-effective operation of electric buses (with a focus on a case study from BVG). Among the pillars of our upcoming issue you’ll find a detailed journey around the European industrial bus&coach landscape. Goal? Providing our readers insights into the changing dynamics among key OEMs in the region. We’ll be then taking you behind the scenes at the Yutong factory in Zhengzhou, that we had the pleasure of visiting in June. Let’s then delve into Iveco Bus’s growing efforts in the zero-emission bus field. Finally, last but not least, a nearly-20-pages comparison between seven 12-meter battery-electric buses, gathered together in Bonn also this year by the German magazine Omnibusspiegel. You’ll find both established players and newcomers side by side: Ebusco 3.0, Hess lighTram 12m, Ikarus 120e, Iveco E-Way, Mercedes eCitaro with new batteries, Otokar e-Kent C, Quantron Cizaris 12 Ev.

A new issue of Sustainable Bus is out today. In this upcoming edition, we’ve curated a diverse and comprehensive range of topics that spotlight the latest developments in the world of sustainable mobility. From cutting-edge technological advancements to market insights and industry transformations, this issue promises to be a captivating exploration of the future of public transportation.

What you could fine inside? Well, a market insight will offer you a detailed look at the European e-bus market, providing you with a comprehensive understanding of the mid-2023 results. The leading e-bus market in Europe is still UK: therefore, we focused our attention on that specific market with a report that sums up strategies, focus, goals of the most prominent industry players.

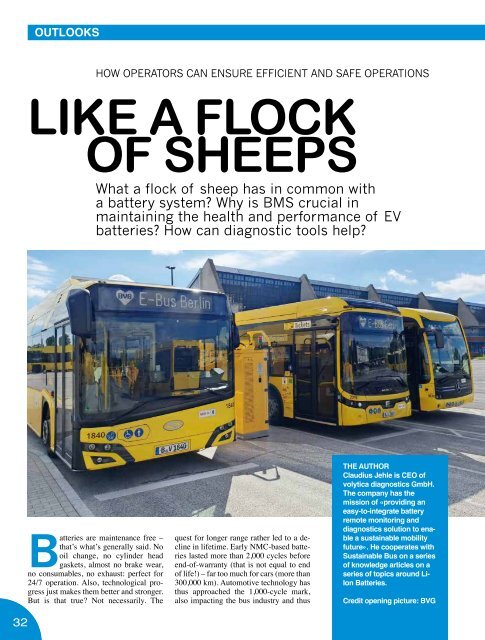

A technology spotlight on the delicate topic of batteries, authored by Claudius Jehle, look at battery management and strategies to ensure the smooth and cost-effective operation of electric buses (with a focus on a case study from BVG).

Among the pillars of our upcoming issue you’ll find a detailed journey around the European industrial bus&coach landscape. Goal? Providing our readers insights into the changing dynamics among key OEMs in the region.

We’ll be then taking you behind the scenes at the Yutong factory in Zhengzhou, that we had the pleasure of visiting in June. Let’s then delve into Iveco Bus’s growing efforts in the zero-emission bus field.

Finally, last but not least, a nearly-20-pages comparison between seven 12-meter battery-electric buses, gathered together in Bonn also this year by the German magazine Omnibusspiegel. You’ll find both established players and newcomers side by side: Ebusco 3.0, Hess lighTram 12m, Ikarus 120e, Iveco E-Way, Mercedes eCitaro with new batteries, Otokar e-Kent C, Quantron Cizaris 12 Ev.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

OUTLOOKS<br />

32<br />

HOW OPERATORS CAN ENSURE EFFICIENT AND SAFE OPERATIONS<br />

LIKE A FLOCK<br />

OF SHEEPS<br />

What a flock of sheep has in common with<br />

a battery system? Why is BMS crucial in<br />

maintaining the health and performance of EV<br />

batteries? How can diagnostic tools help?<br />

Batteries are maintenance free –<br />

that’s what’s generally said. No<br />

oil change, no cylinder head<br />

gaskets, almost no brake wear,<br />

no consumables, no exhaust: perfect for<br />

24/7 operation. Also, technological progress<br />

just makes them better and stronger.<br />

But is that true? Not necessarily. The<br />

quest for longer range rather led to a decline<br />

in lifetime. Early NMC-based batteries<br />

lasted more than 2,000 cycles before<br />

end-of-warranty (that is not equal to end<br />

of life!) – far too much for cars (more than<br />

300,000 km). Automotive technology has<br />

thus approached the 1,000-cycle mark,<br />

also impacting the bus industry and thus<br />

THE AUTHOR<br />

Claudius Jehle is CEO of<br />

volytica diagnostics GmbH.<br />

The company has the<br />

mission of «providing an<br />

easy-to-integrate battery<br />

remote monitoring and<br />

diagnostics solution to enable<br />

a sustainable mobility<br />

future». He cooperates with<br />

Sustainable Bus on a series<br />

of knowledge articles on a<br />

series of topics around Li-<br />

Ion Batteries.<br />

Credit opening picture: BVG<br />

raising the importance of lifetime management<br />

and careful operation.<br />

Are batteries ‘maintenance free’?<br />

But even more important in daily business<br />

is availability and safety. A battery<br />

is like a flock of hundreds of single cells,<br />

with delicate cables, electronics and<br />

sensors tying them together. We know<br />

from diesel engines how vulnerable such<br />

clockworks are to component issues – but<br />

here, something is peculiarly different:<br />

the cells themselves.<br />

Does the weakest sheep determine the behaviour<br />

of the entire flock?<br />

Any difference in quality or property<br />

among the flock of cells will impact the<br />

performance of the entire<br />

herd. The battery management<br />

system (BMS)<br />

is there to handle such<br />

deviations: asymmetries<br />

in voltage/state of charge<br />

are ‘balanced’ out to<br />

some degree, e.g. during<br />

idling after charging. But<br />

if the asymmetry has become<br />

too pronounced, or<br />

if the BMS is unable to<br />

sense it (a huge problem<br />

of LFP), a battery can<br />

just shut down or show unexpected behaviour,<br />

such as sudden standstill, erratic<br />

jumps in State of Charge or significantly<br />

reduced range.<br />

But why do such ‘evil’ asymmetries arise<br />

in the first place?<br />

On balancing, BMS, diagnostics<br />

Balancing works best during rest, so heavy<br />

use reduces balancing efficiency,<br />

especially for LFP. Also, small quality<br />

differences will intensify due to imperfect<br />

cooling. Standard BMS can handle<br />

normal spreads, but outliers always exist.<br />

Also, the electronics can only detect an<br />

existing problem and are limited in predicting<br />

them. All of that is amplified by<br />

strong usage conditions like fast charging<br />

or low temperatures that make it even<br />

worse, raising the likelihood of safety critical,<br />

cell-internal damages.<br />

Fine precursors for these bad things can<br />

be sensed in the interplay of voltages,<br />

currents and temperatures (but: temperature<br />

is the last to react!), but they are<br />

often too subtle and gradual for any BMS<br />

to spot unambiguously and without being<br />

too squeamish. Online diagnostic tools<br />

can give early indications on things that<br />

BVG’S WAY IN DEALING WITH BATTERY TECHNOLOGY<br />

BVG aims to decarbonize its entire bus As a transport company, we want to<br />

fleet with approx. 1,750 electrically deal with this ourselves in order to build<br />

powered buses by 2030. As early as up internal expertise. In doing so, we are<br />

<strong>2023</strong>, 228 e-buses will be on the roads of looking for supportive and experienced<br />

Berlin. A vehicle tender for a framework partners».<br />

contract for new electrically powered<br />

What tangible results have you already<br />

articulated buses is currently underway.<br />

been able to achieve with battery diagnostics?<br />

Kevin Doãn, battery technologist at<br />

BVG, outlines the challenges of the battery<br />

technology for electric buses.<br />

Besides charging infrastructure, what<br />

worries you the most?<br />

Doãn: «The battery technology<br />

of buses is subject to very<br />

dynamic development and is<br />

therefore a key component<br />

of new vehicles. In addition<br />

to passenger safety concerns<br />

and compliance with the extensive<br />

warranty conditions,<br />

we are confronted with a<br />

complex electromobility system.<br />

At present, volatile general<br />

conditions are a constant companion<br />

and make future planning difficult.<br />

Electromobility is currently associated<br />

with high costs, as there is currently no<br />

1:1 replacement of vehicles».<br />

Regarding the battery, which responsibilities<br />

do you see for the manufacturer<br />

and which for the PTOs respectively<br />

owners?<br />

«The vehicle manufacturers are rarely<br />

the battery manufacturers themselves.<br />

So, the high-voltage battery is a subsystem<br />

that the vehicle manufacturers<br />

integrate into their vehicle concepts,<br />

and the responsibility must lie with the<br />

battery manufacturers to monitor the<br />

production process accordingly. As the<br />

operator of the vehicles, I see the responsibility<br />

to ensure the safe operation<br />

of all components, whether through<br />

maintenance intervals or battery diagnostics.<br />

A ‘defective’ battery cell can be<br />

detected much earlier than when it fails.<br />

«Although for the time being only a<br />

small part of our electrically powered<br />

vehicle fleet is being monitored by external<br />

partners, we have already had our<br />

first taste of success. A few months ago,<br />

an anomaly was detected that indicated<br />

a problem with individual cells, with the<br />

potential for vehicle failure. The anomaly<br />

detection allowed the vehicle to be<br />

taken out of service and the battery system<br />

to be repaired by the vehicle manufacturer<br />

within the warranty period».<br />

What does this mean for day-to-day<br />

operations?<br />

«Not only can we convey safety to our<br />

passengers, but we can also prove and<br />

ensure it. By detecting deviations at an<br />

early stage, a technical defect could be<br />

detected, checked, and remedied. This<br />

indirectly increases vehicle availability<br />

in daily operation. Another important<br />

aspect of decarbonisation for us is the<br />

sustainability factor: with battery diagnostics,<br />

the charging management can<br />

be analysed and adjusted to extend the<br />

life of the battery».<br />

Does this incident have any influence<br />

on future decisions?<br />

«Yes. From this case study we have seen<br />

the possibilities that battery diagnostics<br />

/ battery monitoring offer. As BVG, we<br />

must continue to work intensively on<br />

the topic of battery diagnostics, which<br />

means both building up internal knowhow<br />

and working continuously with<br />

partners in the areas of battery, charging<br />

and drive technology».<br />

33