Optimal integrering av energianvändningen vid ... - Gasefuels AB

Optimal integrering av energianvändningen vid ... - Gasefuels AB

Optimal integrering av energianvändningen vid ... - Gasefuels AB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Executive Summary<br />

vii<br />

VÄRMEFORSK<br />

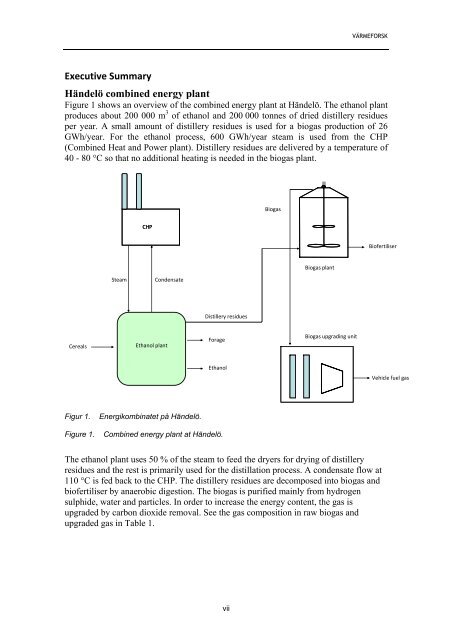

Händelö combined energy plant<br />

Figure 1 shows an overview of the combined energy plant at Händelö. The ethanol plant<br />

produces about 200 000 m 3 of ethanol and 200 000 tonnes of dried distillery residues<br />

per year. A small amount of distillery residues is used for a biogas production of 26<br />

GWh/year. For the ethanol process, 600 GWh/year steam is used from the CHP<br />

(Combined Heat and Power plant). Distillery residues are delivered by a temperature of<br />

40 - 80 °C so that no additional heating is needed in the biogas plant.<br />

Cereals<br />

Steam<br />

CHP<br />

Ethanol plant<br />

Condensate<br />

Figur 1. Energikombinatet på Händelö.<br />

Distillery residues<br />

Forage<br />

Ethanol<br />

Figure 1. Combined energy plant at Händelö.<br />

Biogas<br />

Biogas plant<br />

Biogas upgrading unit<br />

The ethanol plant uses 50 % of the steam to feed the dryers for drying of distillery<br />

residues and the rest is primarily used for the distillation process. A condensate flow at<br />

110 °C is fed back to the CHP. The distillery residues are decomposed into biogas and<br />

biofertiliser by anaerobic digestion. The biogas is purified mainly from hydrogen<br />

sulphide, water and particles. In order to increase the energy content, the gas is<br />

upgraded by carbon dioxide removal. See the gas composition in raw biogas and<br />

upgraded gas in Table 1.<br />

Biofertiliser<br />

Vehicle fuel gas