Optimal integrering av energianvändningen vid ... - Gasefuels AB

Optimal integrering av energianvändningen vid ... - Gasefuels AB

Optimal integrering av energianvändningen vid ... - Gasefuels AB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

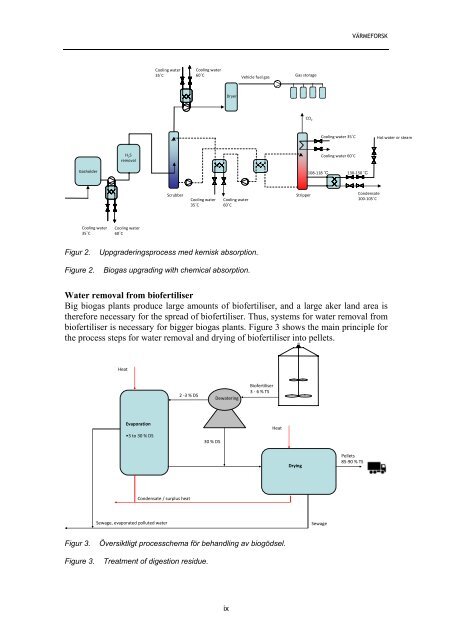

Gasholder<br />

Cooling water<br />

35˚C<br />

H 2S<br />

removal<br />

Cooling water<br />

60˚C<br />

Cooling water<br />

35˚C<br />

Scrubber<br />

Cooling water<br />

60˚C<br />

Cooling water<br />

35˚C<br />

Cooling water<br />

60˚C<br />

ix<br />

Dryer<br />

Vehicle fuel gas<br />

Figur 2. Uppgraderingsprocess med kemisk absorption.<br />

Figure 2. Biogas upgrading with chemical absorption.<br />

Gas storage<br />

CO 2<br />

Stripper<br />

108‐118 ˚C<br />

Cooling water 35˚C<br />

Cooling water 60˚C<br />

VÄRMEFORSK<br />

130‐150 ˚C<br />

Condensate<br />

100‐105˚C<br />

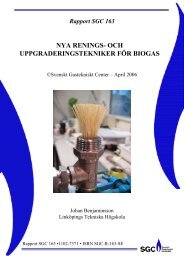

Water removal from biofertiliser<br />

Big biogas plants produce large amounts of biofertiliser, and a large aker land area is<br />

therefore necessary for the spread of biofertiliser. Thus, systems for water removal from<br />

biofertiliser is necessary for bigger biogas plants. Figure 3 shows the main principle for<br />

the process steps for water removal and drying of biofertiliser into pellets.<br />

Heat<br />

Evaporation<br />

•3 to 30 % DS<br />

2 ‐3 % DS<br />

Condensate / surplus heat<br />

Sewage, evaporated polluted water<br />

30 % DS<br />

Dewatering<br />

Biofertiliser<br />

3 ‐ 6 % TS<br />

Figur 3. Översiktligt processchema för behandling <strong>av</strong> biogödsel.<br />

Figure 3. Treatment of digestion residue.<br />

Heat<br />

Drying<br />

Sewage<br />

Pellets<br />

85‐90 % TS<br />

Hot water or steam