MD-500

MD-500

MD-500

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

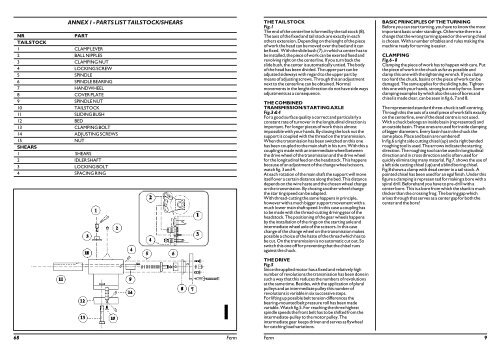

NR PART<br />

TAILSTOCK<br />

1 CLAMP LEVER<br />

2BALL NIPPLES<br />

3 CLAMPING NUT<br />

4 LOCKING SCREW<br />

5 SPINDLE<br />

6 SPINDLE BEARING<br />

7 HANDWHEEL<br />

8 COVER PLATE<br />

9 SPINDLE NUT<br />

10 TAILSTOCK<br />

11 SLIDING BUSH<br />

12BED<br />

13 CLAMPING BOLT<br />

14 ADJUSTING SCREWS<br />

15 NUT<br />

SHEARS<br />

1 SHEARS<br />

2IDLER SHAFT<br />

3 LOCKING BOLT<br />

4 SPACING RING<br />

ANNEX 1 - PARTS LIST TAILSTOCK/SHEARS<br />

1<br />

68 Ferm<br />

THE TAIL STOCK<br />

Fig.1<br />

The end of the centerline is formed by the tail stock (8).<br />

The axis of the fixed and tail stock are exactly in each<br />

others extension. Depending on the lenght of the piece<br />

of work the head can be moved over the bed and it can<br />

be fixed. With the slide bush (7), in which a center has to<br />

be installed, the piece of work can be exerted fixed and<br />

revolving right on the centerline. If you turn back the<br />

slide bush, the center is automatically untied. The body<br />

of the head has been divided. The upper part can be<br />

adjusted sideways with regard to the upper part by<br />

means of adjusting screws. Through this an adjustment<br />

next to the centerline can be obtained. Normal<br />

movements in the lenght direction do not have side ways<br />

adjustments as a consequence.<br />

THE COMBINED<br />

TRANSMISSION/STARTING AXLE<br />

Fig.3 & 4<br />

For a good surface quality a correct and particularly a<br />

constant rate of turnover in the longitudinal direction is<br />

important. For longer pieces of work this is almost<br />

impossible with your hands. By closing the lock nut the<br />

support is coupled with the thread on the transmission.<br />

When the transmission has been switched on this one<br />

has been coupled to the main shaft in his turn. With this a<br />

coupling is made with an intermediate wheel between<br />

the drive wheel of the transmission and the drive wheel<br />

for the longitudinal feed on the headstock. This happens<br />

because of an adjustment of the change wheel scissors,<br />

watch fig. 3 and 4.<br />

At each rotation of the main shaft the support will move<br />

itself over a certain distance along the bed. This distance<br />

depends on the wire haste and the chosen wheel change<br />

on the transmission. By chosing another wheel change<br />

the star ting speed can be adapted.<br />

With thread-cutting the same happens in principle,<br />

however with a much bigger support movement with a<br />

much lower main shaft speed. In this case a coupling has<br />

to be made with the thread-cutting driving gear of the<br />

headstock. The positioning of the gear wheels happens<br />

by the installation of the rings on the starting axle and<br />

intermediate wheel axle of the scissors. In this case<br />

change of the change wheel on the transmission makes<br />

possible a choice of the haste of the thread which has to<br />

be cut. On the transmission is no automatic cut out. So<br />

switch this one off for preventing that the chisel runs<br />

against the chuck.<br />

THE DRIVE<br />

Fig.5<br />

Since the applied motor has a fixed and relatively high<br />

number of revolutions the transmission has been done in<br />

such a way that this reduces the numbers of revolutions<br />

at the same time. Besides, with the application of plural<br />

pulleys and an intermediate pulley this number of<br />

revolutions is variable in six successive steps.<br />

For lifting up possible belt tension differences the<br />

bearing-mounted belt pressure roll has been made<br />

variable. Watch fig.5. For reaching the three highest<br />

spindle speeds the front belt has to be shifted from the<br />

intermediate-pulley to the motor pulley. The<br />

intermediate gear keeps driven and serves as flywheel<br />

for catching load variations.<br />

BASIC PRINCIPLES OF THE TURNING<br />

Before you can start turning, you have to know the most<br />

important basic under standings. Otherwise there is a<br />

change that the wrong turning speed or the wrong chisel<br />

is chosen. With a number of tables and rules making the<br />

machine ready for turning is easier.<br />

CLAMPING<br />

Fig.6 - 8<br />

Clamping the piece of work has to happen with care. Put<br />

the piece of work in the chuck as far as possible and<br />

clamp this one with the tightening wrench. If you clamp<br />

too hard the chuck, basins or the piece of work can be<br />

damaged. The same applies for the sliding tube. Tighten<br />

this one with your hands, strong but not by force. Some<br />

clamping examples by which also the use of bores and<br />

chisel is made clear, can be seen in fig.6, 7 and 8.<br />

The represented standard three-chuck is self-centring.<br />

Through this the axis of a small piece of work falls exactly<br />

on the centerline, even if the dead centre is not used.<br />

With a chuck belongs an inside basin (represented) and<br />

an outside basin. These ones are used for inside clamping<br />

of bigger diameters. Every basin has in the chuck the<br />

same place. Place and basin are numbered!<br />

In fig.6 a right side cutting chisel (up) and a right bended<br />

roughing tool is used. The arrows indicate the starting<br />

direction. The roughing tool can be used in longitudinal<br />

direction and in cross direction and is often used for<br />

quickly elimina ting many material. Fig 7. shows the use of<br />

a left side cutting chisel (up) and a blind boring chisel.<br />

Fig.8 shows a clamp with dead center in a tail stock. A<br />

pointed chisel has been used for an egal finish. Under this<br />

figure a clamping is represen ted for making a bore with a<br />

spiral drill. Beforehand you have to pre-drill with a<br />

center bore. This is a bore from which the shank is much<br />

thicker than the crossing frog. The boring gap which<br />

arises through that serves as a center gap for both the<br />

center and the bore!<br />

Ferm 9