TUNNEL ENGINEERING

TUNNEL ENGINEERING

TUNNEL ENGINEERING

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

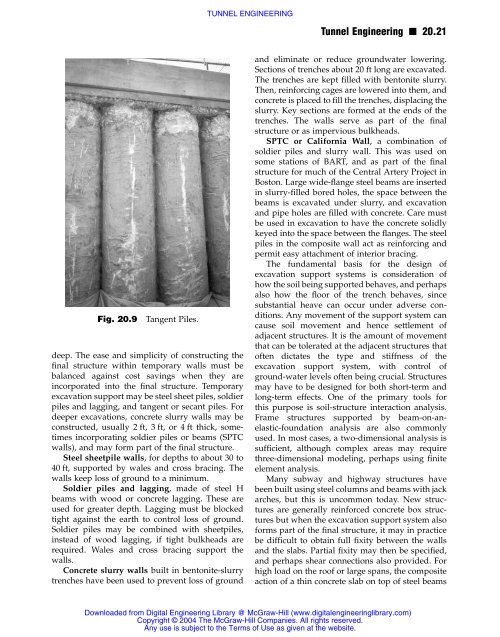

Fig. 20.9 Tangent Piles.<br />

deep. The ease and simplicity of constructing the<br />

final structure within temporary walls must be<br />

balanced against cost savings when they are<br />

incorporated into the final structure. Temporary<br />

excavation support may be steel sheet piles, soldier<br />

piles and lagging, and tangent or secant piles. For<br />

deeper excavations, concrete slurry walls may be<br />

constructed, usually 2 ft, 3 ft, or 4 ft thick, sometimes<br />

incorporating soldier piles or beams (SPTC<br />

walls), and may form part of the final structure.<br />

Steel sheetpile walls, for depths to about 30 to<br />

40 ft, supported by wales and cross bracing. The<br />

walls keep loss of ground to a minimum.<br />

Soldier piles and lagging, made of steel H<br />

beams with wood or concrete lagging. These are<br />

used for greater depth. Lagging must be blocked<br />

tight against the earth to control loss of ground.<br />

Soldier piles may be combined with sheetpiles,<br />

instead of wood lagging, if tight bulkheads are<br />

required. Wales and cross bracing support the<br />

walls.<br />

Concrete slurry walls built in bentonite-slurry<br />

trenches have been used to prevent loss of ground<br />

<strong>TUNNEL</strong> <strong>ENGINEERING</strong><br />

Tunnel Engineering n 20.21<br />

and eliminate or reduce groundwater lowering.<br />

Sections of trenches about 20 ft long are excavated.<br />

The trenches are kept filled with bentonite slurry.<br />

Then, reinforcing cages are lowered into them, and<br />

concrete is placed to fill the trenches, displacing the<br />

slurry. Key sections are formed at the ends of the<br />

trenches. The walls serve as part of the final<br />

structure or as impervious bulkheads.<br />

SPTC or California Wall, a combination of<br />

soldier piles and slurry wall. This was used on<br />

some stations of BART, and as part of the final<br />

structure for much of the Central Artery Project in<br />

Boston. Large wide-flange steel beams are inserted<br />

in slurry-filled bored holes, the space between the<br />

beams is excavated under slurry, and excavation<br />

and pipe holes are filled with concrete. Care must<br />

be used in excavation to have the concrete solidly<br />

keyed into the space between the flanges. The steel<br />

piles in the composite wall act as reinforcing and<br />

permit easy attachment of interior bracing.<br />

The fundamental basis for the design of<br />

excavation support systems is consideration of<br />

how the soil being supported behaves, and perhaps<br />

also how the floor of the trench behaves, since<br />

substantial heave can occur under adverse conditions.<br />

Any movement of the support system can<br />

cause soil movement and hence settlement of<br />

adjacent structures. It is the amount of movement<br />

that can be tolerated at the adjacent structures that<br />

often dictates the type and stiffness of the<br />

excavation support system, with control of<br />

ground-water levels often being crucial. Structures<br />

may have to be designed for both short-term and<br />

long-term effects. One of the primary tools for<br />

this purpose is soil-structure interaction analysis.<br />

Frame structures supported by beam-on-anelastic-foundation<br />

analysis are also commonly<br />

used. In most cases, a two-dimensional analysis is<br />

sufficient, although complex areas may require<br />

three-dimensional modeling, perhaps using finite<br />

element analysis.<br />

Many subway and highway structures have<br />

been built using steel columns and beams with jack<br />

arches, but this is uncommon today. New structures<br />

are generally reinforced concrete box structures<br />

but when the excavation support system also<br />

forms part of the final structure, it may in practice<br />

be difficult to obtain full fixity between the walls<br />

and the slabs. Partial fixity may then be specified,<br />

and perhaps shear connections also provided. For<br />

high load on the roof or large spans, the composite<br />

action of a thin concrete slab on top of steel beams<br />

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)<br />

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.<br />

Any use is subject to the Terms of Use as given at the website.