TUNNEL ENGINEERING

TUNNEL ENGINEERING

TUNNEL ENGINEERING

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The ventilation system also must be capable of<br />

controlling smoke and hot gases in case of fire (see<br />

Ventilation Systems for Road Tunnels following).<br />

The Federal government or health authorities of<br />

states place restrictions on permissible carbon<br />

monoxide (CO) content. With new standards<br />

limiting contaminants in vehicle exhaust gases,<br />

however, it may eventually be possible to meet the<br />

CO limitations without extensive increase in<br />

ventilation. Engineers should check current rules<br />

at time of design.<br />

Haze from vehicle exhaust gases, particularly<br />

from Diesel engined vehicles, does reduce visibility<br />

in the tunnel. In practice, when the CO level within<br />

the tunnel is maintained at levels as proposed in<br />

Table 20.1, adequate dilution of the irritating parts<br />

of exhaust gases and adequate visibility is assured.<br />

New road tunnels built in the United States<br />

must comply with the time-weighted limits for<br />

concentration of CO established by the U.S.<br />

Environmental Protection Agency and the Federal<br />

Highway Administration. These limits are listed in<br />

Table 20.1.<br />

Other countries may set other standards for<br />

carbon monoxide (CO) concentrations within their<br />

tunnels. The World Road Association (PIARC)<br />

publications provide documentation on the<br />

subject.<br />

For tunnels in which traffic may incorporate a<br />

high percentage (10% or more) of diesel vehicles,<br />

the ventilation requirements for dilution of NO x<br />

particles of nitrogen and particulates (smoke)<br />

become significant. The NOx emitted by vehicles<br />

consists mainly of nitric oxide (NO), which<br />

oxidizes in the atmosphere to form nitrogen<br />

dioxide (NO 2). Based on exposure limits recommended<br />

by the American Conference of<br />

Governmental Industrial Hygienists and a typical<br />

4-to-1 ratio for NO to NO2, the maximum<br />

permissible concentration of NO x is about 10 ppm.<br />

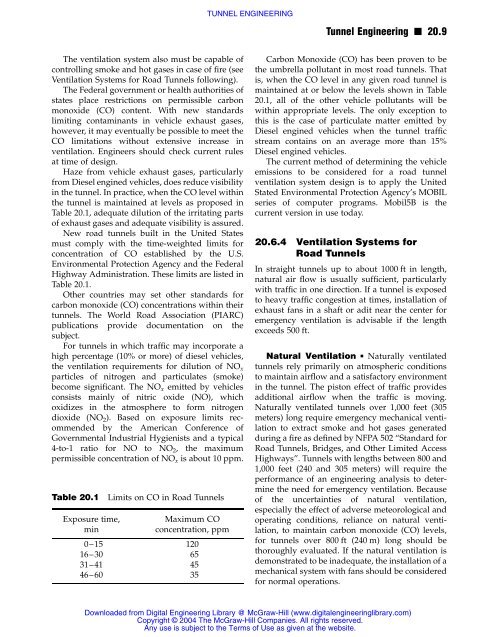

Table 20.1 Limits on CO in Road Tunnels<br />

Exposure time,<br />

min<br />

Maximum CO<br />

concentration, ppm<br />

0–15 120<br />

16–30 65<br />

31–41 45<br />

46–60 35<br />

<strong>TUNNEL</strong> <strong>ENGINEERING</strong><br />

Tunnel Engineering n 20.9<br />

Carbon Monoxide (CO) has been proven to be<br />

the umbrella pollutant in most road tunnels. That<br />

is, when the CO level in any given road tunnel is<br />

maintained at or below the levels shown in Table<br />

20.1, all of the other vehicle pollutants will be<br />

within appropriate levels. The only exception to<br />

this is the case of particulate matter emitted by<br />

Diesel engined vehicles when the tunnel traffic<br />

stream contains on an average more than 15%<br />

Diesel engined vehicles.<br />

The current method of determining the vehicle<br />

emissions to be considered for a road tunnel<br />

ventilation system design is to apply the United<br />

Stated Environmental Protection Agency’s MOBIL<br />

series of computer programs. Mobil5B is the<br />

current version in use today.<br />

20.6.4 Ventilation Systems for<br />

Road Tunnels<br />

In straight tunnels up to about 1000 ft in length,<br />

natural air flow is usually sufficient, particularly<br />

with traffic in one direction. If a tunnel is exposed<br />

to heavy traffic congestion at times, installation of<br />

exhaust fans in a shaft or adit near the center for<br />

emergency ventilation is advisable if the length<br />

exceeds 500 ft.<br />

Natural Ventilation n Naturally ventilated<br />

tunnels rely primarily on atmospheric conditions<br />

to maintain airflow and a satisfactory environment<br />

in the tunnel. The piston effect of traffic provides<br />

additional airflow when the traffic is moving.<br />

Naturally ventilated tunnels over 1,000 feet (305<br />

meters) long require emergency mechanical ventilation<br />

to extract smoke and hot gases generated<br />

during a fire as defined by NFPA 502 “Standard for<br />

Road Tunnels, Bridges, and Other Limited Access<br />

Highways”. Tunnels with lengths between 800 and<br />

1,000 feet (240 and 305 meters) will require the<br />

performance of an engineering analysis to determine<br />

the need for emergency ventilation. Because<br />

of the uncertainties of natural ventilation,<br />

especially the effect of adverse meteorological and<br />

operating conditions, reliance on natural ventilation,<br />

to maintain carbon monoxide (CO) levels,<br />

for tunnels over 800 ft (240 m) long should be<br />

thoroughly evaluated. If the natural ventilation is<br />

demonstrated to be inadequate, the installation of a<br />

mechanical system with fans should be considered<br />

for normal operations.<br />

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)<br />

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.<br />

Any use is subject to the Terms of Use as given at the website.