TUNNEL ENGINEERING

TUNNEL ENGINEERING

TUNNEL ENGINEERING

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

unless the rock is highly abrasive, causing<br />

excessive wear of drills.<br />

Too much information can never be provided<br />

for the engineer, to produce a realistic design, and<br />

for the contractors, to prepare sound bids. Even at<br />

best, unforeseen difficulties must be expected.<br />

In addition to geological surveys and borings<br />

(Art. 20.5), engineers may use electric-resistivity<br />

measurements and gamma-ray absorption for<br />

information on depth and characteristics of rock<br />

formations. Information also may be obtained from<br />

the U.S. Geological Survey, which has extended its<br />

scope and geophysical studies beyond the mining<br />

field. Where geological conditions are particularly<br />

hard to evaluate or are especially severe, exploratory<br />

pilot tunnels, about 10 10 ft, may be driven<br />

part way from each end or for the entire length of a<br />

tunnel, prior to final design and advertising of<br />

construction. TBMs may be used for pilot tunnels<br />

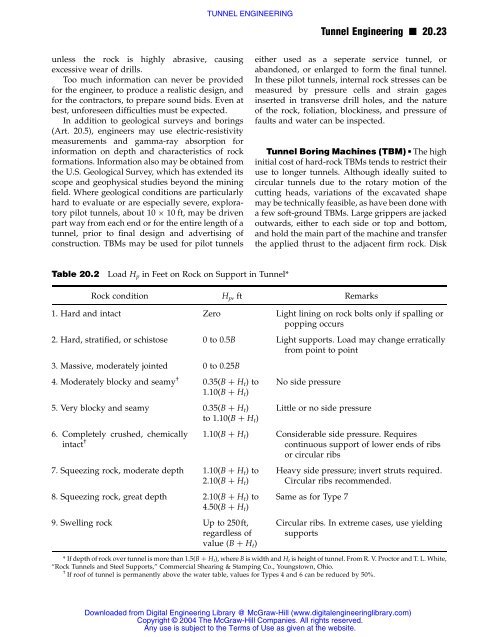

Table 20.2 Load Hp in Feet on Rock on Support in Tunnel*<br />

either used as a seperate service tunnel, or<br />

abandoned, or enlarged to form the final tunnel.<br />

In these pilot tunnels, internal rock stresses can be<br />

measured by pressure cells and strain gages<br />

inserted in transverse drill holes, and the nature<br />

of the rock, foliation, blockiness, and pressure of<br />

faults and water can be inspected.<br />

Tunnel Boring Machines (TBM) n The high<br />

initial cost of hard-rock TBMs tends to restrict their<br />

use to longer tunnels. Although ideally suited to<br />

circular tunnels due to the rotary motion of the<br />

cutting heads, variations of the excavated shape<br />

may be technically feasible, as have been done with<br />

a few soft-ground TBMs. Large grippers are jacked<br />

outwards, either to each side or top and bottom,<br />

and hold the main part of the machine and transfer<br />

the applied thrust to the adjacent firm rock. Disk<br />

Rock condition Hp, ft Remarks<br />

1. Hard and intact Zero Light lining on rock bolts only if spalling or<br />

popping occurs<br />

2. Hard, stratified, or schistose 0 to 0.5B Light supports. Load may change erratically<br />

from point to point<br />

3. Massive, moderately jointed 0 to 0.25B<br />

4. Moderately blocky and seamy †<br />

0.35(B þ Ht)to 1.10(B þ Ht)<br />

No side pressure<br />

5. Very blocky and seamy 0.35(B þ H t)<br />

to 1.10(B þ Ht)<br />

6. Completely crushed, chemically<br />

intact †<br />

<strong>TUNNEL</strong> <strong>ENGINEERING</strong><br />

7. Squeezing rock, moderate depth 1.10(B þ Ht) to<br />

2.10(B þ Ht)<br />

8. Squeezing rock, great depth 2.10(B þ Ht) to<br />

4.50(B þ Ht)<br />

9. Swelling rock Up to 250ft,<br />

regardless of<br />

value (B þ Ht)<br />

Little or no side pressure<br />

1.10(B þ H t) Considerable side pressure. Requires<br />

continuous support of lower ends of ribs<br />

or circular ribs<br />

Heavy side pressure; invert struts required.<br />

Circular ribs recommended.<br />

Same as for Type 7<br />

Tunnel Engineering n 20.23<br />

Circular ribs. In extreme cases, use yielding<br />

supports<br />

* If depth of rock over tunnel is more than 1.5(B þ Ht), where B is width and Ht is height of tunnel. From R. V. Proctor and T. L. White,<br />

“Rock Tunnels and Steel Supports,” Commercial Shearing & Stamping Co., Youngstown, Ohio.<br />

† If roof of tunnel is permanently above the water table, values for Types 4 and 6 can be reduced by 50%.<br />

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)<br />

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.<br />

Any use is subject to the Terms of Use as given at the website.