TUNNEL ENGINEERING

TUNNEL ENGINEERING

TUNNEL ENGINEERING

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

effective. Bolts are tightened with hydraulic or<br />

pneumatic wrenches where possible otherwise<br />

with hand wrenches.<br />

Welded steel segments, similar in shape to castiron<br />

segments, have been used for economic<br />

reasons in some subaqueous tunnels. They were<br />

welded in jigs to tolerances as close as practicable,<br />

but flanges were not machined and no calking<br />

grooves were provided. Difficulties were experienced<br />

in making them watertight with gaskets.<br />

An improved design includes calking grooves<br />

and fabrication tolerances similar to those for<br />

cast iron.<br />

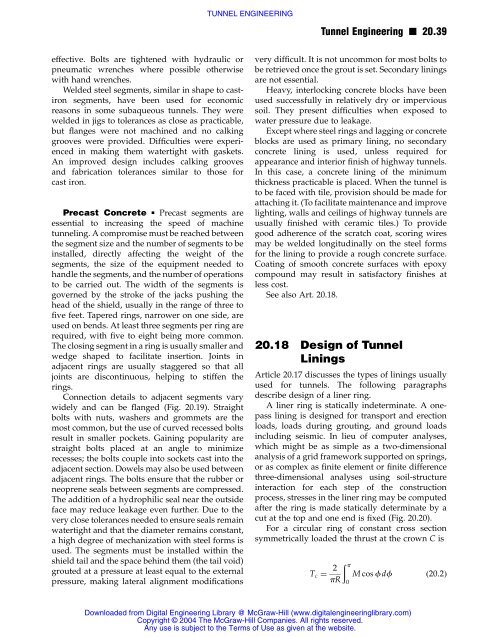

Precast Concrete n Precast segments are<br />

essential to increasing the speed of machine<br />

tunneling. A compromise must be reached between<br />

the segment size and the number of segments to be<br />

installed, directly affecting the weight of the<br />

segments, the size of the equipment needed to<br />

handle the segments, and the number of operations<br />

to be carried out. The width of the segments is<br />

governed by the stroke of the jacks pushing the<br />

head of the shield, usually in the range of three to<br />

five feet. Tapered rings, narrower on one side, are<br />

used on bends. At least three segments per ring are<br />

required, with five to eight being more common.<br />

The closing segment in a ring is usually smaller and<br />

wedge shaped to facilitate insertion. Joints in<br />

adjacent rings are usually staggered so that all<br />

joints are discontinuous, helping to stiffen the<br />

rings.<br />

Connection details to adjacent segments vary<br />

widely and can be flanged (Fig. 20.19). Straight<br />

bolts with nuts, washers and grommets are the<br />

most common, but the use of curved recessed bolts<br />

result in smaller pockets. Gaining popularity are<br />

straight bolts placed at an angle to minimize<br />

recesses; the bolts couple into sockets cast into the<br />

adjacent section. Dowels may also be used between<br />

adjacent rings. The bolts ensure that the rubber or<br />

neoprene seals between segments are compressed.<br />

The addition of a hydrophilic seal near the outside<br />

face may reduce leakage even further. Due to the<br />

very close tolerances needed to ensure seals remain<br />

watertight and that the diameter remains constant,<br />

a high degree of mechanization with steel forms is<br />

used. The segments must be installed within the<br />

shield tail and the space behind them (the tail void)<br />

grouted at a pressure at least equal to the external<br />

pressure, making lateral alignment modifications<br />

<strong>TUNNEL</strong> <strong>ENGINEERING</strong><br />

Tunnel Engineering n 20.39<br />

very difficult. It is not uncommon for most bolts to<br />

be retrieved once the grout is set. Secondary linings<br />

are not essential.<br />

Heavy, interlocking concrete blocks have been<br />

used successfully in relatively dry or impervious<br />

soil. They present difficulties when exposed to<br />

water pressure due to leakage.<br />

Except where steel rings and lagging or concrete<br />

blocks are used as primary lining, no secondary<br />

concrete lining is used, unless required for<br />

appearance and interior finish of highway tunnels.<br />

In this case, a concrete lining of the minimum<br />

thickness practicable is placed. When the tunnel is<br />

to be faced with tile, provision should be made for<br />

attaching it. (To facilitate maintenance and improve<br />

lighting, walls and ceilings of highway tunnels are<br />

usually finished with ceramic tiles.) To provide<br />

good adherence of the scratch coat, scoring wires<br />

may be welded longitudinally on the steel forms<br />

for the lining to provide a rough concrete surface.<br />

Coating of smooth concrete surfaces with epoxy<br />

compound may result in satisfactory finishes at<br />

less cost.<br />

See also Art. 20.18.<br />

20.18 Design of Tunnel<br />

Linings<br />

Article 20.17 discusses the types of linings usually<br />

used for tunnels. The following paragraphs<br />

describe design of a liner ring.<br />

A liner ring is statically indeterminate. A onepass<br />

lining is designed for transport and erection<br />

loads, loads during grouting, and ground loads<br />

including seismic. In lieu of computer analyses,<br />

which might be as simple as a two-dimensional<br />

analysis of a grid framework supported on springs,<br />

or as complex as finite element or finite difference<br />

three-dimensional analyses using soil-structure<br />

interaction for each step of the construction<br />

process, stresses in the liner ring may be computed<br />

after the ring is made statically determinate by a<br />

cut at the top and one end is fixed (Fig. 20.20).<br />

For a circular ring of constant cross section<br />

symmetrically loaded the thrust at the crown C is<br />

Tc ¼ 2<br />

pR<br />

ð p<br />

0<br />

M cos f df (20:2)<br />

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)<br />

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.<br />

Any use is subject to the Terms of Use as given at the website.