TUNNEL ENGINEERING

TUNNEL ENGINEERING

TUNNEL ENGINEERING

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

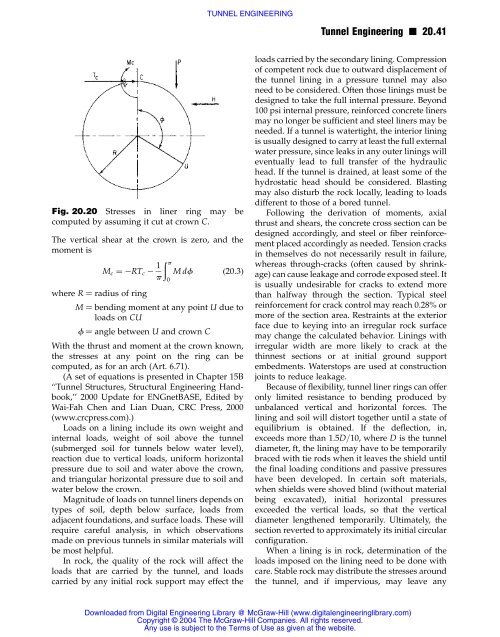

Fig. 20.20 Stresses in liner ring may be<br />

computed by assuming it cut at crown C.<br />

The vertical shear at the crown is zero, and the<br />

moment is<br />

ðp 1<br />

Mc ¼ RTc Mdf (20:3)<br />

p 0<br />

where R ¼ radius of ring<br />

M ¼ bending moment at any point U due to<br />

loads on CU<br />

f ¼ angle between U and crown C<br />

With the thrust and moment at the crown known,<br />

the stresses at any point on the ring can be<br />

computed, as for an arch (Art. 6.71).<br />

(A set of equations is presented in Chapter 15B<br />

‘‘Tunnel Structures, Structural Engineering Handbook,’’<br />

2000 Update for ENGnetBASE, Edited by<br />

Wai-Fah Chen and Lian Duan, CRC Press, 2000<br />

(www.crcpress.com).)<br />

Loads on a lining include its own weight and<br />

internal loads, weight of soil above the tunnel<br />

(submerged soil for tunnels below water level),<br />

reaction due to vertical loads, uniform horizontal<br />

pressure due to soil and water above the crown,<br />

and triangular horizontal pressure due to soil and<br />

water below the crown.<br />

Magnitude of loads on tunnel liners depends on<br />

types of soil, depth below surface, loads from<br />

adjacent foundations, and surface loads. These will<br />

require careful analysis, in which observations<br />

made on previous tunnels in similar materials will<br />

be most helpful.<br />

In rock, the quality of the rock will affect the<br />

loads that are carried by the tunnel, and loads<br />

carried by any initial rock support may effect the<br />

<strong>TUNNEL</strong> <strong>ENGINEERING</strong><br />

Tunnel Engineering n 20.41<br />

loads carried by the secondary lining. Compression<br />

of competent rock due to outward displacement of<br />

the tunnel lining in a pressure tunnel may also<br />

need to be considered. Often those linings must be<br />

designed to take the full internal pressure. Beyond<br />

100 psi internal pressure, reinforced concrete liners<br />

may no longer be sufficient and steel liners may be<br />

needed. If a tunnel is watertight, the interior lining<br />

is usually designed to carry at least the full external<br />

water pressure, since leaks in any outer linings will<br />

eventually lead to full transfer of the hydraulic<br />

head. If the tunnel is drained, at least some of the<br />

hydrostatic head should be considered. Blasting<br />

may also disturb the rock locally, leading to loads<br />

different to those of a bored tunnel.<br />

Following the derivation of moments, axial<br />

thrust and shears, the concrete cross section can be<br />

designed accordingly, and steel or fiber reinforcement<br />

placed accordingly as needed. Tension cracks<br />

in themselves do not necessarily result in failure,<br />

whereas through-cracks (often caused by shrinkage)<br />

can cause leakage and corrode exposed steel. It<br />

is usually undesirable for cracks to extend more<br />

than halfway through the section. Typical steel<br />

reinforcement for crack control may reach 0.28% or<br />

more of the section area. Restraints at the exterior<br />

face due to keying into an irregular rock surface<br />

may change the calculated behavior. Linings with<br />

irregular width are more likely to crack at the<br />

thinnest sections or at initial ground support<br />

embedments. Waterstops are used at construction<br />

joints to reduce leakage.<br />

Because of flexibility, tunnel liner rings can offer<br />

only limited resistance to bending produced by<br />

unbalanced vertical and horizontal forces. The<br />

lining and soil will distort together until a state of<br />

equilibrium is obtained. If the deflection, in,<br />

exceeds more than 1.5D/10, where D is the tunnel<br />

diameter, ft, the lining may have to be temporarily<br />

braced with tie rods when it leaves the shield until<br />

the final loading conditions and passive pressures<br />

have been developed. In certain soft materials,<br />

when shields were shoved blind (without material<br />

being excavated), initial horizontal pressures<br />

exceeded the vertical loads, so that the vertical<br />

diameter lengthened temporarily. Ultimately, the<br />

section reverted to approximately its initial circular<br />

configuration.<br />

When a lining is in rock, determination of the<br />

loads imposed on the lining need to be done with<br />

care. Stable rock may distribute the stresses around<br />

the tunnel, and if impervious, may leave any<br />

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)<br />

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.<br />

Any use is subject to the Terms of Use as given at the website.