TUNNEL ENGINEERING

TUNNEL ENGINEERING

TUNNEL ENGINEERING

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

hoe is used to loosen the soil and scoop it onto the<br />

conveyor. From there, it is discharged on a loading<br />

conveyor mounted on a movable carriage behind<br />

the shield. The loading conveyor dumps it into<br />

mine cars, usually of about 4-yd 3 capacity in large<br />

tunnels. The muck trains are rolled back through<br />

the tunnels to an access shaft. The individual cars<br />

are hoisted up the access shaft and dumped into<br />

hoppers for discharging into trucks.<br />

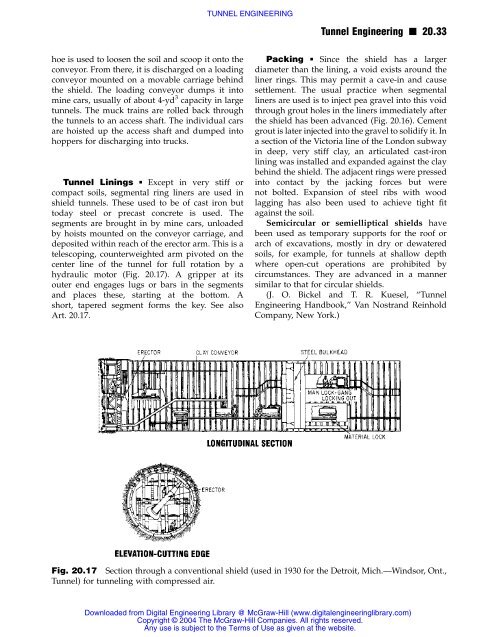

Tunnel Linings n Except in very stiff or<br />

compact soils, segmental ring liners are used in<br />

shield tunnels. These used to be of cast iron but<br />

today steel or precast concrete is used. The<br />

segments are brought in by mine cars, unloaded<br />

by hoists mounted on the conveyor carriage, and<br />

deposited within reach of the erector arm. This is a<br />

telescoping, counterweighted arm pivoted on the<br />

center line of the tunnel for full rotation by a<br />

hydraulic motor (Fig. 20.17). A gripper at its<br />

outer end engages lugs or bars in the segments<br />

and places these, starting at the bottom. A<br />

short, tapered segment forms the key. See also<br />

Art. 20.17.<br />

<strong>TUNNEL</strong> <strong>ENGINEERING</strong><br />

Tunnel Engineering n 20.33<br />

Packing n Since the shield has a larger<br />

diameter than the lining, a void exists around the<br />

liner rings. This may permit a cave-in and cause<br />

settlement. The usual practice when segmental<br />

liners are used is to inject pea gravel into this void<br />

through grout holes in the liners immediately after<br />

the shield has been advanced (Fig. 20.16). Cement<br />

grout is later injected into the gravel to solidify it. In<br />

a section of the Victoria line of the London subway<br />

in deep, very stiff clay, an articulated cast-iron<br />

lining was installed and expanded against the clay<br />

behind the shield. The adjacent rings were pressed<br />

into contact by the jacking forces but were<br />

not bolted. Expansion of steel ribs with wood<br />

lagging has also been used to achieve tight fit<br />

against the soil.<br />

Semicircular or semielliptical shields have<br />

been used as temporary supports for the roof or<br />

arch of excavations, mostly in dry or dewatered<br />

soils, for example, for tunnels at shallow depth<br />

where open-cut operations are prohibited by<br />

circumstances. They are advanced in a manner<br />

similar to that for circular shields.<br />

(J. O. Bickel and T. R. Kuesel, “Tunnel<br />

Engineering Handbook,” Van Nostrand Reinhold<br />

Company, New York.)<br />

Fig. 20.17 Section through a conventional shield (used in 1930 for the Detroit, Mich.—Windsor, Ont.,<br />

Tunnel) for tunneling with compressed air.<br />

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)<br />

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.<br />

Any use is subject to the Terms of Use as given at the website.