You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

side of the vehicle to the other, while fore-aft<br />

(or longitudinal) load shift brings about a change<br />

in load distribution between axle groups, which<br />

can affect roll stability and braking performance.<br />

A commonly accepted threshold for safe lateral<br />

load shift is 100mm. Research conducted by<br />

Roaduser Systems Ltd and funded by RIRDC,<br />

showed that the maximum lateral movement for<br />

all of the properly restrained loads tested is less<br />

than 100mm. The load shift at the centre-ofgravity<br />

is less than 50mm, which represents a<br />

movement of around 3% of the axle track width.<br />

Longitudinally, this equates to an effective<br />

centre-of-gravity shift of around 300mm based<br />

on trailer wheelbase.<br />

This research also found that there are small<br />

but worthwhile benefits gained by using more<br />

effective load restraint methods such as<br />

double-strapping or “double-dogging” of<br />

single straps (one load binder on each side of<br />

the load for a single strap).<br />

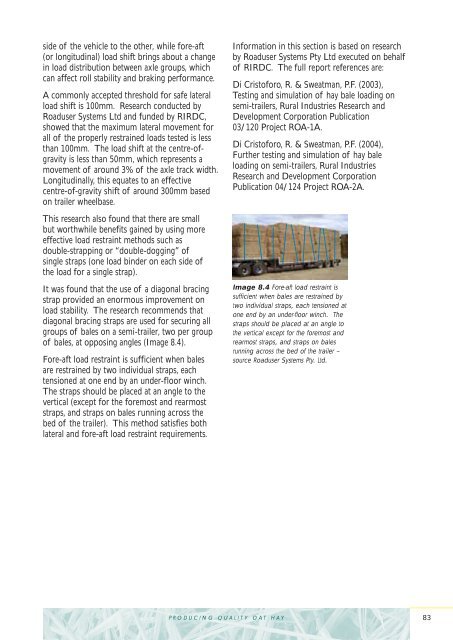

It was found that the use of a diagonal bracing<br />

strap provided an enormous improvement on<br />

load stability. The research recommends that<br />

diagonal bracing straps are used for securing all<br />

groups of bales on a semi-trailer, two per group<br />

of bales, at opposing angles (Image 8.4).<br />

Fore-aft load restraint is sufficient when bales<br />

are restrained by two individual straps, each<br />

tensioned at one end by an under-floor winch.<br />

The straps should be placed at an angle to the<br />

vertical (except for the foremost and rearmost<br />

straps, and straps on bales running across the<br />

bed of the trailer). This method satisfies both<br />

lateral and fore-aft load restraint requirements.<br />

PRODUCING QUALITY OAT HAY<br />

Information in this section is based on research<br />

by Roaduser Systems Pty Ltd executed on behalf<br />

of RIRDC. The full report references are:<br />

Di Cristoforo, R. & Sweatman, P.F. (2003),<br />

Testing and simulation of hay bale loading on<br />

semi-trailers, Rural Industries Research and<br />

Development Corporation Publication<br />

03/120 Project ROA-1A.<br />

Di Cristoforo, R. & Sweatman, P.F. (2004),<br />

Further testing and simulation of hay bale<br />

loading on semi-trailers, Rural Industries<br />

Research and Development Corporation<br />

Publication 04/124 Project ROA-2A.<br />

Image 8.4 Fore-aft load restraint is<br />

sufficient when bales are restrained by<br />

two individual straps, each tensioned at<br />

one end by an under-floor winch. The<br />

straps should be placed at an angle to<br />

the vertical except for the foremost and<br />

rearmost straps, and straps on bales<br />

running across the bed of the trailer –<br />

source Roaduser Systems Pty. Ltd.<br />

83