Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PRINCIPLES OF DRILL JIGS<br />

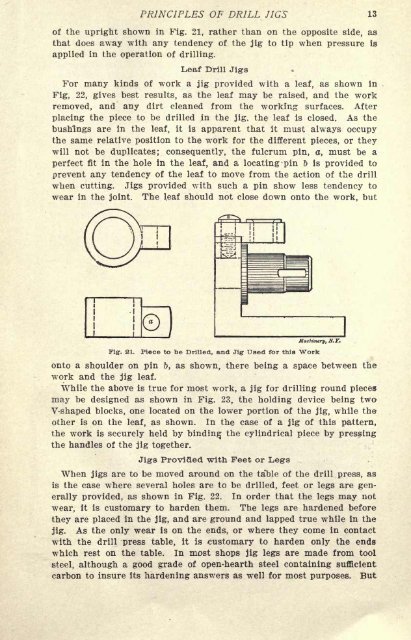

<strong>of</strong> the upright shown in Fig. 21, rather than on the opposite side, as<br />

that does away with any tendency <strong>of</strong> the jig to tip when pressure is<br />

applied in the operation <strong>of</strong> drilling.<br />

Leaf <strong>Drill</strong> <strong>Jigs</strong><br />

For many kinds <strong>of</strong> work a jig provided with a leaf, as shown in<br />

Fig, 22, gives best results, as the leaf may be raised, and the work<br />

removed, and any dirt cleaned from the working surfaces. After<br />

placing the piece to be drilled in the jig, the leaf is closed. As the<br />

bushings are in the leaf, it is apparent that it must always occupy<br />

the same relative position to the work for the different pieces, or they<br />

will not be duplicates; consequently, the fulcrum pin, a, must be a<br />

perfect fit in the hole in the leaf, and a locating -pin & is provided to<br />

prevent any tendency <strong>of</strong> the leaf to move from the action <strong>of</strong> the drill<br />

when cutting. <strong>Jigs</strong> provided with such a pin show less tendency to<br />

wear in the joint. The leaf should not close down onto the work, but<br />

i I<br />

t 1<br />

13