Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

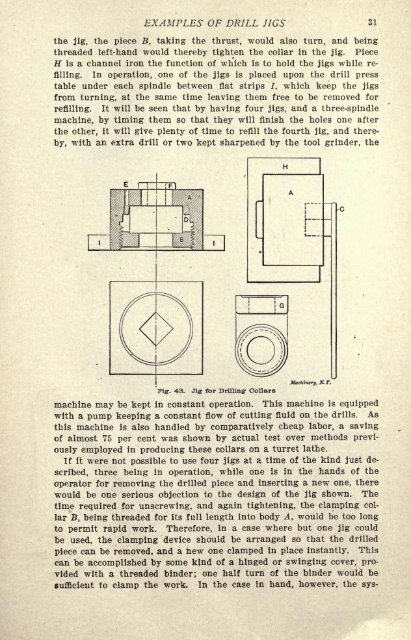

EXAMPLES OF DRILL JIGS<br />

the jig, the piece B, taking the thrust, would also turn, and being<br />

threaded left-hand would thereby tighten the collar in the jig. Piece<br />

H is a channel iron the function <strong>of</strong> which is to hold the jigs while re-<br />

one <strong>of</strong> the jigs is placed upon the drill press<br />

filling. In operation, .<br />

table under each spindle between flat strips 7, which keep the jigs<br />

from turning, at the same time leaving them free to be removed for<br />

refilling. It will be seen that by having four jigs, and a three-spindle<br />

machine, by timing them so that they will finish the holes one after<br />

the other, it will give plenty <strong>of</strong> time to refill the fourth jig, and there-<br />

by, with an extra drill or two kept sharpened by the tool grinder, the<br />

Fig. 43. Jig for <strong>Drill</strong>ing Collars<br />

<strong>Machinery</strong>, N.r.<br />

machine may be kept in constant operation. This machine is equipped<br />

with a pump keeping a constant flow <strong>of</strong> cutting fluid on the drills. As<br />

this machine is also handled by comparatively cheap labor, a saving<br />

<strong>of</strong> almost 75 per cent was shown by actual test over methods previ-<br />

ously employed in producing these collars on a turret lathe.<br />

If ft were not possible to use four jigs at a time <strong>of</strong> the kind just de-<br />

scribed, three being in operation, while one is in the hands <strong>of</strong> the<br />

operator for removing the drilled piece and inserting a new one, there<br />

would be one serious objection to the design <strong>of</strong> the jig shown. The<br />

time required for unscrewing, and again tightening, the clamping col-<br />

lar B, being threaded for its full length into body A, would be too long<br />

to permit rapid work. Therefore, in a case where but one jig could<br />

be used, the clamping device should be arranged so that the drilled<br />

piece can be removed, and a new one clamped in place instantly. This<br />

can be accomplished by some kind <strong>of</strong> a hinged or swinging cover, provided<br />

with a threaded binder; one half turn <strong>of</strong> the binder would be<br />

sufficient to clamp the work. In the case in hand, however, the sys-<br />

31