Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8 No. 3 DRILL JIGS<br />

more holes are drilled, and before all are drilled, it would cause a<br />

variation that would in all probability spoil the piece <strong>of</strong> work. When<br />

but a few pieces are to be drilled with a jig it is not generally con-<br />

sidered advisable to make jigs with fastening devices, the wor^ being<br />

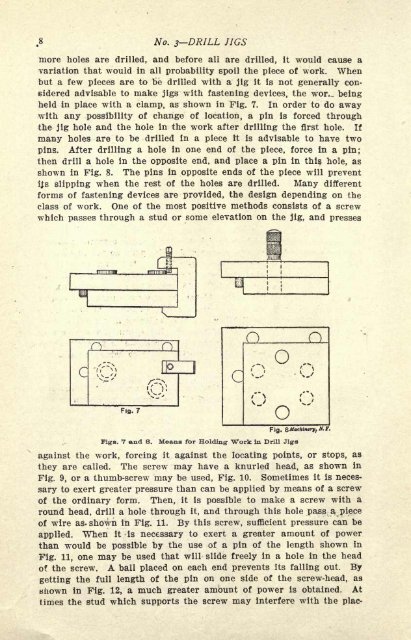

held in place with a clamp, as shown in Fig. 7. In order to do away<br />

with any possibility <strong>of</strong> change <strong>of</strong> location, a pin is forced through<br />

the jig hole and the hole in the work after drilling the first hole. If<br />

many holes are to be drilled in a piece it is advisable to have two<br />

pins. After drilling a hole in one end <strong>of</strong> the piece, force in a pin;<br />

then drill a hole in the opposite end, and place a pin in this hole, as<br />

shown in Fig. 8. The pins in opposite ends <strong>of</strong> the piece will prevent<br />

ijs slipping when the rest <strong>of</strong> the holes are drilled. Many different<br />

forms <strong>of</strong> fastening devices are provided, the design depending on the<br />

class <strong>of</strong> work. One <strong>of</strong> the most positive methods consists <strong>of</strong> a screw<br />

which passes through a stud or some elevation on the jig, and presses<br />

C<br />

Fig. 7<br />

c