Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

14 No. 3 DRILL JIGS<br />

as few shops carry such steel in stock, crucible tool steel is generally<br />

used. The ends <strong>of</strong> the legs should be ground true with the seating<br />

surface that is, where the work rests <strong>of</strong> the jig. To accomplish this<br />

a surface grinder hould be used. As the operation <strong>of</strong> grinding leaves<br />

a number <strong>of</strong> projections on the surface ground, and as these ridges<br />

or projections would wear away as the legs were moved back and forth<br />

t<br />

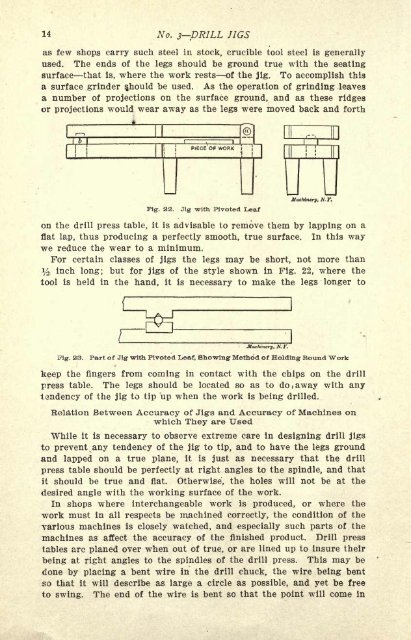

PIECE OF WORK I<br />

Fig. 22. Jig with Pivoted Leaf<br />

<strong>Machinery</strong>, If. T.<br />

on the drill press table, it is advisable to remove them by lapping on a<br />

flat lap, thus producing a perfectly smooth, true surface. In this way<br />

we reduce the wear to a minimum.<br />

For certain classes <strong>of</strong> jigs the legs may be short, not more than<br />

% inch long; but for jigs <strong>of</strong> the style shown in Fig. 22, where the<br />

tool is held in the hand, it is necessary to make the legs longer to<br />

<strong>Machinery</strong>, If. Y.<br />

Pig. 23. Part <strong>of</strong> Jig -with Pivoted Leaf, Showing Method <strong>of</strong> Holding Round Work<br />

freep the fingers from coming in contact with the chips on the drill<br />

press table. The legs should be located so as to do away with any<br />

tendency <strong>of</strong> the jig to tip up when the work is being drilled.<br />

Relation Between Accuracy <strong>of</strong> <strong>Jigs</strong> and Accuracy <strong>of</strong> Machines on<br />

which They are Used<br />

While it is necessary to observe extreme care in designing drill jigs<br />

to prevent any tendency <strong>of</strong> the jig to tip, and to have the legs ground<br />

and lapped on a true plane, it is just as necessary that the drill<br />

press table should be perfectly at right angles to the spindle, and that<br />

it should be true and flat. Otherwise, the holes will not be at the<br />

desired angle with the working surface <strong>of</strong> the work.<br />

In shops where interchangeable work is produced, or where the<br />

work must in all respects be machined correctly, the condition <strong>of</strong> the<br />

various machines is closely watched, and especially such parts <strong>of</strong> the<br />

machines as affect the accuracy <strong>of</strong> the finished product. <strong>Drill</strong> press<br />

tables are planed over when out <strong>of</strong> true, or are lined up to insure their<br />

being at right angles to the spindles <strong>of</strong> the drill press. This may be<br />

done by placing a bent wire in the drill chuck, the wire being bent<br />

so that it will describe as large a circle as possible, and yet be free<br />

to swing. The end <strong>of</strong> the wire is bent so that the point will come in