Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PRINCIPLES OF DRILL JIGS<br />

At times jigs are made <strong>of</strong> such size and design that it seems wise<br />

to core the bushing holes. In such cases it is necessary, in order that<br />

we may lay out the location <strong>of</strong> the centers <strong>of</strong> desired holes, to press<br />

a piece <strong>of</strong> sheet steel or sheet brass into the cored hole, as shown in<br />

Fig. 27, and locate the center on this piece. When the holes are properly<br />

located for machining, the sheet metal may be removed and the<br />

holes finished to the desired size. If an error <strong>of</strong> 0.001 or 0.002 inch is<br />

not permissible, the method described above should not be employed.<br />

Method Employed for Highest Degree <strong>of</strong> Accuracy<br />

Where extreme accuracy is essential we must locate round pieces <strong>of</strong><br />

steel on the face <strong>of</strong> our work. These pieces <strong>of</strong> steel are called buttons<br />

and are <strong>of</strong> exact size and perfectly round. To do away with any possibility<br />

<strong>of</strong> their becoming bruised in any way, they are hardened and<br />

carefully ground to size. The buttons are attached to the work by<br />

means <strong>of</strong> machine screws, as shown in Fig. 28, the holes in the but-<br />

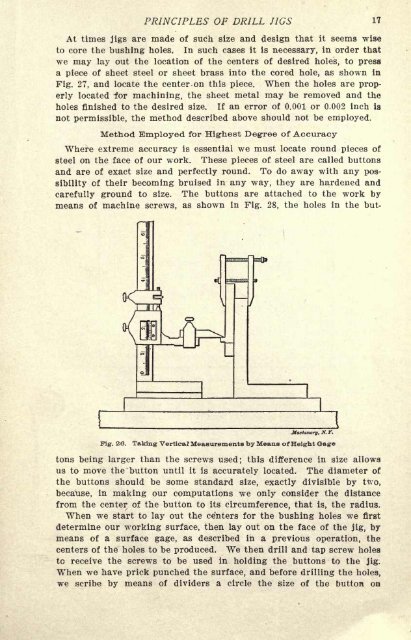

Fig. 26.<br />

Jtactnnery.N.r.<br />

Taking Vertical Measurements by Means <strong>of</strong> Height Gage<br />

tons being larger than the screws used; this difference in size allows<br />

us to move the button until it is accurately located. The diameter <strong>of</strong><br />

the buttons should be some standard size, exactly divisible by two,<br />

because, in making our computations we only consider the distance<br />

from the center <strong>of</strong> the button to its circumference, that is, the radius.<br />

When we start to lay out the centers for the bushing holes we first<br />

determine our working surface, then lay out on the face <strong>of</strong> the jig, by<br />

means <strong>of</strong> a surface gage, as described in a previous operation, the<br />

centers <strong>of</strong> the holes to be produced. We then drill and tap screw holes<br />

to receive the screws to be used in holding the buttons to the jig.<br />

When we have prick punched the surface, and before drilling the holes,<br />

we scribe by means <strong>of</strong> dividers a circle the size <strong>of</strong> the button on<br />

17