Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

54 No. 3 DRILL JIGS<br />

In the following outline <strong>of</strong> a system for getting the most out <strong>of</strong><br />

the tools in the shop, the word "jig" will be meant to include all jigs,<br />

templets, fixtures, appliances, etc., which aid in the rapid and accurate<br />

machining <strong>of</strong> parts. With such assumptions allowed, the necessity for<br />

some systematic scheme <strong>of</strong> management for the use and care <strong>of</strong> the<br />

jigs should be apparent. However, it is not uncommon, even in these<br />

days, when the jig is admittedly one <strong>of</strong> the main factors instrumental<br />

in developing the shops <strong>of</strong> the past (where machinery was "built"),<br />

into the shops <strong>of</strong> the present (where it is "manufactured"), to find concerns<br />

where the jigs are given no consideration beyond designing them<br />

and keeping them in a questionable state <strong>of</strong> repair. The whole tool<br />

or jig scheme, however, is so interwoven with the entire shop that<br />

the success <strong>of</strong> a system cannot be dependent entirely upon any one<br />

person, but upon the co-operation <strong>of</strong> all.<br />

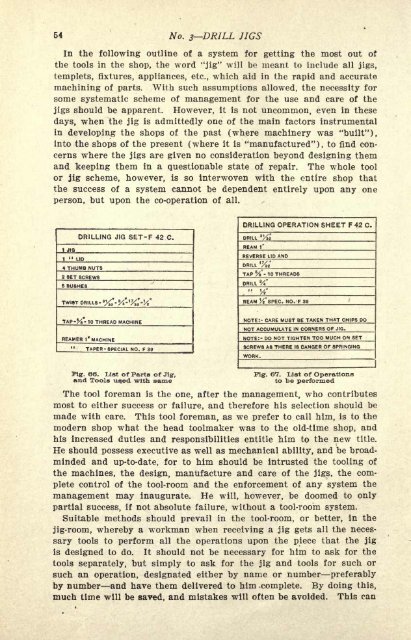

DRILLING JIG SET-F 42 C.<br />

4 THUMB NUTS<br />

2 SET SCREWS<br />

TWI8T DRILLS-<br />

I- 10 THREAD MACHINE<br />

REAMER t* MACHINE<br />

TAPER -SPECIAL NO. F 39<br />

Fig. 66. List <strong>of</strong> Parts <strong>of</strong> Jig,<br />

and. Tools used -with same<br />

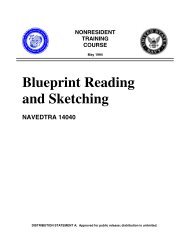

DRILLING OPERATION SHEET F 42 C.<br />

REVERSE LID AND<br />

TAP 6 /a- 10 THREADS<br />

REAM K'SPEC. NO. F 39<br />

NOTE:- CARE MUST BE TAKEN THAT CHIPS DO<br />

NOT ACCUMULATE IN CORNERS OF JIG.<br />

NOTE:- DO NOT TIGHTEN TOO MUCH ON SET<br />

SCREWS AS THERE IS DANGER OF SPRINGING<br />

WORK.<br />

Fig. 67. List <strong>of</strong> Operations<br />

to be performed<br />

The tool foreman is the one, after the management, who contributes<br />

most to either success or failure, and therefore his selection should be<br />

made with care. This tool foreman, as we prefer to call him, is to the<br />

modern shop what the head toolmaker was to the old-time shop, and<br />

his increased duties and responsibilities entitle him to the new title.<br />

He should possess executive as well as mechanical ability, and be broadminded<br />

and up-to-date, for to him should be intrusted the tooling <strong>of</strong><br />

the machines, the design, manufacture and care <strong>of</strong> the jigs, the complete<br />

control <strong>of</strong> the tool-room and the enforcement <strong>of</strong> any system the<br />

management may inaugurate. He will, however, be doomed to only<br />

partial success, if not absolute failure, without a tool-room system.<br />

Suitable methods should prevail in the tool-room, or better, in the<br />

jig-room, whereby a workman when receiving a jig gets all the neces-<br />

sary tools to perform all the operations upon the piece that the jig<br />

is designed to do. It should not be necessary for him to ask for the<br />

tools separately, but simply to ask for the jig and tools for such or<br />

such an operation, designated either by name or number preferably<br />

by number and have them delivered to him -complete. By doing this,<br />

much time will be saved, and mistakes will <strong>of</strong>ten be avoided. This can