Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

42 No. 3 DRILL JIGS<br />

line, and when they are so aligned, it is impossible for the hole to<br />

come out <strong>of</strong> center on either end <strong>of</strong> the boss. The simplest and safest<br />

way to align these holes is to run a single-pointed boring bar through<br />

the screw bushing into the bottom <strong>of</strong> the jig, after the screw bushing<br />

has been fitted to the jig, the shank <strong>of</strong> the boring bar, <strong>of</strong> course, being<br />

a good fit in the hole <strong>of</strong> the screw bushing, which has been previously<br />

lapped to size. On the larger sizes <strong>of</strong> bushings, it has been found<br />

advantageous to use a good quality <strong>of</strong> machine steel, case-hardened and<br />

having a smaller tool steel bushing inserted in the center. When made<br />

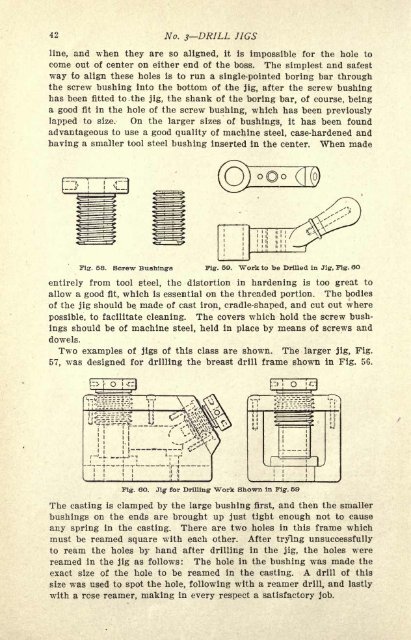

Fig. 58. Screw Bushings Fig. 59. Work to be <strong>Drill</strong>ed in Jig, Pig. 6O<br />

entirely from tool steel, the distortion in hardening is too great to<br />

allow a good fit, which is essential on the threaded portion. The bodies<br />

<strong>of</strong> the jig should be. made <strong>of</strong> cast iron, cradle-shaped, and cut out where<br />

possible, to facilitate cleaning. The covers which hold the screw bushings<br />

should be <strong>of</strong> machine steel, held in place by means <strong>of</strong> screws and<br />

dowels.<br />

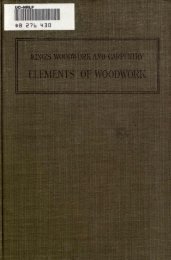

Two examples <strong>of</strong> jigs <strong>of</strong> this class are shown. The larger jig, Fig.<br />

57, was designed for drilling the breast drill frame shown in Fig. 56.<br />

Fig. 6O. Jig for <strong>Drill</strong>ing "Work Shown in Fig. 59<br />

The casting is clamped by the large bushing first, and then the smaller<br />

bushings on the ends are brought up just tight enough not to cause<br />

any spring in the casting. There are two holes in this frame which<br />

must be reamed square with each other. After trying unsuccessfully<br />

to ream the holes by hand after drilling in the jig, the holes were<br />

reamed in the jig as follows: The hole in the bushing was made the<br />

exact size <strong>of</strong> the hole to be reamed in the casting. A drill <strong>of</strong> this<br />

size was used to spot the hole, following with a reamer drill, and lastly<br />

with a rose reamer, making in every respect a satisfactory job.