Consolidated Annual Report 2012 and Single-Entity ... - PVA TePla AG

Consolidated Annual Report 2012 and Single-Entity ... - PVA TePla AG

Consolidated Annual Report 2012 and Single-Entity ... - PVA TePla AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Centralized energy generation <strong>and</strong> fixed distribution that<br />

began with electrification around 130 years ago have become<br />

a thing of the past. The grid of the future is no longer<br />

a one-way street. The aim is to integrate <strong>and</strong> coordinate<br />

many different decentralized sources with varying outputs<br />

into a single system. The challenge is similar to that of the<br />

internet revolution, except that instead of Web 2.0, we are<br />

talking about eGrid 2.0! And with its vacuum heat treatment<br />

furnaces, <strong>PVA</strong> <strong>TePla</strong> also plays a role in this segment.<br />

These systems are used to manufacture components such<br />

as vacuum circuit breakers, which are used to disconnect<br />

or feed energy back into the grid. In flexible grids, this technology<br />

is becoming increasingly important!<br />

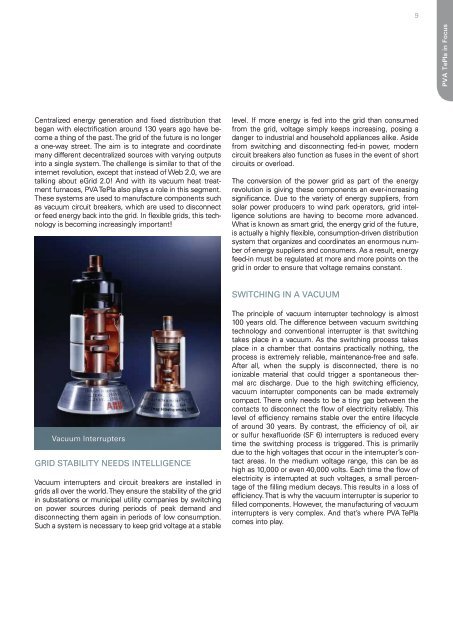

Vacuum Interrupters<br />

GRID STAbILITY NEEDS INTELLIGENCE<br />

Vacuum interrupters <strong>and</strong> circuit breakers are installed in<br />

grids all over the world. They ensure the stability of the grid<br />

in substations or municipal utility companies by switching<br />

on power sources during periods of peak dem<strong>and</strong> <strong>and</strong><br />

disconnecting them again in periods of low consumption.<br />

Such a system is necessary to keep grid voltage at a stable<br />

level. If more energy is fed into the grid than consumed<br />

from the grid, voltage simply keeps increasing, posing a<br />

danger to industrial <strong>and</strong> household appliances alike. Aside<br />

from switching <strong>and</strong> disconnecting fed-in power, modern<br />

circuit breakers also function as fuses in the event of short<br />

circuits or overload.<br />

The conversion of the power grid as part of the energy<br />

revolution is giving these components an ever-increasing<br />

significance. Due to the variety of energy suppliers, from<br />

solar power producers to wind park operators, grid intelligence<br />

solutions are having to become more advanced.<br />

What is known as smart grid, the energy grid of the future,<br />

is actually a highly flexible, consumption-driven distribution<br />

system that organizes <strong>and</strong> coordinates an enormous number<br />

of energy suppliers <strong>and</strong> consumers. As a result, energy<br />

feed-in must be regulated at more <strong>and</strong> more points on the<br />

grid in order to ensure that voltage remains constant.<br />

SWITCHING IN A VACUUM<br />

The principle of vacuum interrupter technology is almost<br />

100 years old. The difference between vacuum switching<br />

technology <strong>and</strong> conventional interrupter is that switching<br />

takes place in a vacuum. As the switching process takes<br />

place in a chamber that contains practically nothing, the<br />

process is extremely reliable, maintenance-free <strong>and</strong> safe.<br />

After all, when the supply is disconnected, there is no<br />

ionizable material that could trigger a spontaneous thermal<br />

arc discharge. Due to the high switching efficiency,<br />

vacuum interrupter components can be made extremely<br />

compact. There only needs to be a tiny gap between the<br />

contacts to disconnect the flow of electricity reliably. This<br />

level of efficiency remains stable over the entire lifecycle<br />

of around 30 years. By contrast, the efficiency of oil, air<br />

or sulfur hexafluoride (SF 6) interrupters is reduced every<br />

time the switching process is triggered. This is primarily<br />

due to the high voltages that occur in the interrupter’s contact<br />

areas. In the medium voltage range, this can be as<br />

high as 10,000 or even 40,000 volts. Each time the flow of<br />

electricity is interrupted at such voltages, a small percentage<br />

of the filling medium decays. This results in a loss of<br />

efficiency. That is why the vacuum interrupter is superior to<br />

filled components. However, the manufacturing of vacuum<br />

interrupters is very complex. And that’s where <strong>PVA</strong> <strong>TePla</strong><br />

comes into play.<br />

9<br />

<strong>PVA</strong> <strong>TePla</strong> in Focus