2005 Annual Report - SBM Offshore

2005 Annual Report - SBM Offshore

2005 Annual Report - SBM Offshore

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Report</strong> of the Board of Management<br />

conditions and BP is planning on using these terminals as<br />

back up systems in the event a passing hurricane damages<br />

the regular oil export infrastructure. In such circumstances a<br />

tanker would be moored to the CALM and be utilised as a<br />

temporary FSO with small shuttle tankers taking the crude to<br />

shore.<br />

CALM buoy for Trafigura installed at the Tema refinery in Ghana<br />

Apart from the above order from BP, the Company secured in<br />

<strong>2005</strong> the following new terminal orders:<br />

• from BP Trinidad and Tobago LLC for the supply of a ‘stock<br />

buoy’ to replace one of BP’s terminals at the Galeota Point<br />

refinery, supplied by the Company in the seventies;<br />

• from Soilmare S.r.L., for the design and supply of a<br />

complete CALM terminal for the Mellitah Upgrading<br />

Project of Agip Oil Co. Ltd Libya;<br />

• from Waha Oil Company for the supply of a CALM buoy for<br />

the terminal in Ras El Sider, Libya;<br />

• from Fred Olsen for the supply of a CALM system for the<br />

export of oil produced by a spread moored FPSO to be installed<br />

in the Addax operated Antan field offshore Nigeria;<br />

• from the Willbros Group for the supply of a CALM system<br />

to be installed at the Escravos terminal in Nigeria. The<br />

system will be used for the export of the products of the<br />

‘Gas To Liquid’ plant of Chevron, currently under<br />

construction.<br />

The orders for these terminals are executed in Monaco and in<br />

Houston.<br />

26<br />

Design Services and Supply of Special<br />

Components<br />

In addition to their active participation in the execution of a<br />

large number of the contracts described above, Gusto and<br />

MSC in Schiedam as well as GustoMSC Inc (GMI) in Houston<br />

obtained and executed a large variety of orders for design<br />

services, in certain cases combined with the supply of<br />

proprietary hardware components. A number of the most<br />

significant orders are described hereafter.<br />

Basic Design Packages for New Facilities<br />

• Maersk Contractors ordered four cantilever jack-ups of<br />

MSC design from the KeppelFels Shipyard for delivery in<br />

the period from 2007 to 2009. The basic design for these<br />

units is provided by MSC under a license agreement<br />

between MSC and KeppelFels. This project was the result<br />

of a year long design customisation study with Maersk<br />

Contractors. The jack-up units are designated for<br />

operation in 100 metre water depth in moderate<br />

environmental conditions;<br />

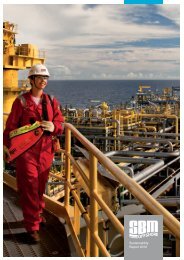

• Maersk Contractors ordered two drilling semisubmersibles<br />

of joint KeppelFels-MSC design from the<br />

KeppelFels Shipyard for delivery in the period from 2008 to<br />

2009. The basic design for these units is provided by MSC<br />

Drilling semi-submersible for Maersk Contractors; an MSC design