ALKON 50-70 INST apice a GB.pmd - Unical Lattner Condensing ...

ALKON 50-70 INST apice a GB.pmd - Unical Lattner Condensing ...

ALKON 50-70 INST apice a GB.pmd - Unical Lattner Condensing ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

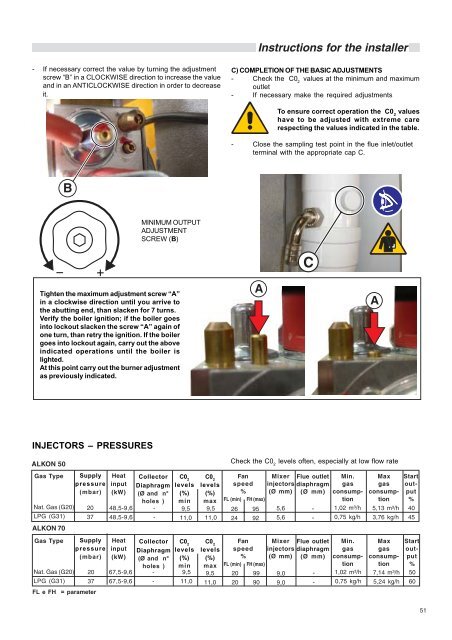

- If necessary correct the value by turning the adjustment<br />

screw “B” in a CLOCKWISE direction to increase the value<br />

and in an ANTICLOCKWISE direction in order to decrease<br />

it.<br />

<strong>ALKON</strong> <strong>50</strong><br />

<strong>ALKON</strong> <strong>70</strong><br />

20<br />

37<br />

FL e FH = parameter<br />

48,5-9,6<br />

48,5-9,6<br />

MINIMUM OUTPUT<br />

ADJUSTMENT<br />

SCREW (B)<br />

Tighten the maximum adjustment screw “A”<br />

in a clockwise direction until you arrive to<br />

the abutting end, than slacken for 7 turns.<br />

Verify the boiler ignition; if the boiler goes<br />

into lockout slacken the screw “A” again of<br />

one turn, than retry the ignition. If the boiler<br />

goes into lockout again, carry out the above<br />

indicated operations until the boiler is<br />

lighted.<br />

At this point carry out the burner adjustment<br />

as previously indicated.<br />

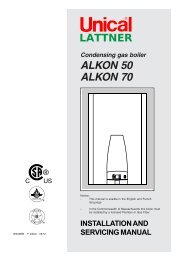

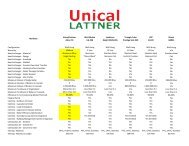

INJECTORS – PRESSURES<br />

Gas Type Supply<br />

pressure<br />

(mbar)<br />

Nat. Gas (G20)<br />

LPG (G31)<br />

Heat<br />

input<br />

(kW)<br />

Collector<br />

Diaphragm<br />

(Ø and n°<br />

holes )<br />

-<br />

-<br />

C02 levels<br />

(%)<br />

min<br />

9,5<br />

11,0<br />

Gas Type Supply<br />

pressure<br />

Heat<br />

input<br />

Collector<br />

Diaphragm<br />

C02 levels<br />

(mbar) (kW) (Ø and n° (%)<br />

holes ) min<br />

Nat. Gas (G20) 20 67,5-9,6 - 9,5<br />

LPG (G31) 37 67,5-9,6 - 11,0<br />

Instructions for the installer<br />

C) COMPLETION OF THE BASIC ADJUSTMENTS<br />

- Check the C0 2 values at the minimum and maximum<br />

outlet<br />

- If necessary make the required adjustments<br />

To ensure correct operation the C0 2 values<br />

have to be adjusted with extreme care<br />

respecting the values indicated in the table.<br />

- Close the sampling test point in the flue inlet/outlet<br />

terminal with the appropriate cap C.<br />

Check the C0 2 levels often, especially at low flow rate<br />

C02 levels<br />

Fan<br />

speed<br />

Mixer Flue outlet<br />

injectors diaphragm<br />

Min.<br />

gas<br />

Max<br />

gas<br />

(%) % (Ø mm) (Ø mm) consumpconsump- max FL (min) FH (max)<br />

tiontion 9,5 26 95 5,6 - 1,02 m³/h 5,13 m³/h<br />

11,0 24 92 5,6 - 0,75 kg/h 3,76 kg/h<br />

Start<br />

output<br />

%<br />

C02 levels<br />

Fan<br />

speed<br />

Mixer Flue outlet<br />

injectors diaphragm<br />

Min.<br />

gas<br />

Max<br />

gas<br />

Start<br />

out-<br />

(%) % (Ø mm) (Ø mm) consumpconsumpput max FL (min) FH (max)<br />

tiontion %<br />

9,5 20 99 9,0 - 1,02 m³/h 7,14 m³/h <strong>50</strong><br />

11,0 20 90 9,0 - 0,75 kg/h 5,24 kg/h 60<br />

40<br />

45<br />

51