Design and Voltage Supply of High-Speed Induction - Aaltodoc

Design and Voltage Supply of High-Speed Induction - Aaltodoc

Design and Voltage Supply of High-Speed Induction - Aaltodoc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

42<br />

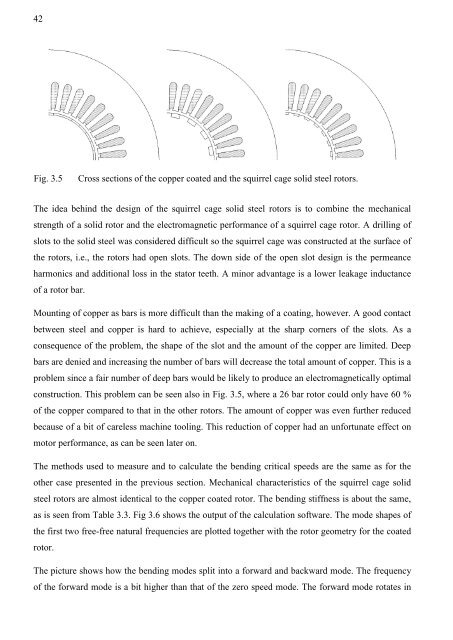

Fig. 3.5 Cross sections <strong>of</strong> the copper coated <strong>and</strong> the squirrel cage solid steel rotors.<br />

The idea behind the design <strong>of</strong> the squirrel cage solid steel rotors is to combine the mechanical<br />

strength <strong>of</strong> a solid rotor <strong>and</strong> the electromagnetic performance <strong>of</strong> a squirrel cage rotor. A drilling <strong>of</strong><br />

slots to the solid steel was considered difficult so the squirrel cage was constructed at the surface <strong>of</strong><br />

the rotors, i.e., the rotors had open slots. The down side <strong>of</strong> the open slot design is the permeance<br />

harmonics <strong>and</strong> additional loss in the stator teeth. A minor advantage is a lower leakage inductance<br />

<strong>of</strong> a rotor bar.<br />

Mounting <strong>of</strong> copper as bars is more difficult than the making <strong>of</strong> a coating, however. A good contact<br />

between steel <strong>and</strong> copper is hard to achieve, especially at the sharp corners <strong>of</strong> the slots. As a<br />

consequence <strong>of</strong> the problem, the shape <strong>of</strong> the slot <strong>and</strong> the amount <strong>of</strong> the copper are limited. Deep<br />

bars are denied <strong>and</strong> increasing the number <strong>of</strong> bars will decrease the total amount <strong>of</strong> copper. This is a<br />

problem since a fair number <strong>of</strong> deep bars would be likely to produce an electromagnetically optimal<br />

construction. This problem can be seen also in Fig. 3.5, where a 26 bar rotor could only have 60 %<br />

<strong>of</strong> the copper compared to that in the other rotors. The amount <strong>of</strong> copper was even further reduced<br />

because <strong>of</strong> a bit <strong>of</strong> careless machine tooling. This reduction <strong>of</strong> copper had an unfortunate effect on<br />

motor performance, as can be seen later on.<br />

The methods used to measure <strong>and</strong> to calculate the bending critical speeds are the same as for the<br />

other case presented in the previous section. Mechanical characteristics <strong>of</strong> the squirrel cage solid<br />

steel rotors are almost identical to the copper coated rotor. The bending stiffness is about the same,<br />

as is seen from Table 3.3. Fig 3.6 shows the output <strong>of</strong> the calculation s<strong>of</strong>tware. The mode shapes <strong>of</strong><br />

the first two free-free natural frequencies are plotted together with the rotor geometry for the coated<br />

rotor.<br />

The picture shows how the bending modes split into a forward <strong>and</strong> backward mode. The frequency<br />

<strong>of</strong> the forward mode is a bit higher than that <strong>of</strong> the zero speed mode. The forward mode rotates in