Download - Evonik Industries

Download - Evonik Industries

Download - Evonik Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

10 DesIGnInG WItH PoLYMeRs<br />

Measuring kinematic<br />

viscosity, which indicates<br />

how much force is<br />

required to get a liquid<br />

to flow<br />

elements35 Issue 2|2011<br />

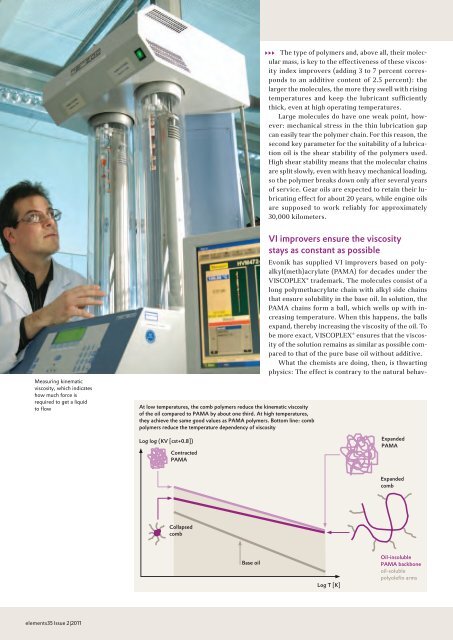

At low temperatures, the comb polymers reduce the kinematic viscosity<br />

of the oil compared to PAMA by about one third. At high temperatures,<br />

they achieve the same good values as PAMA polymers. Bottom line: comb<br />

polymers reduce the temperature dependency of viscosity<br />

Log log (KV [cst+0.8])<br />

Contracted<br />

PAMA<br />

Collapsed<br />

comb<br />

Base oil<br />

333 The type of polymers and, above all, their molecular<br />

mass, is key to the effectiveness of these viscosity<br />

index improvers (adding 3 to 7 percent corresponds<br />

to an additive content of 2.5 percent): the<br />

larger the molecules, the more they swell with rising<br />

temper atures and keep the lubricant sufficiently<br />

thick, even at high operating temperatures.<br />

Large molecules do have one weak point, however:<br />

mechanical stress in the thin lubrication gap<br />

can easily tear the polymer chain. For this reason, the<br />

second key parameter for the suitability of a lubrication<br />

oil is the shear stability of the polymers used.<br />

High shear stability means that the molecular chains<br />

are split slowly, even with heavy mechanical loading,<br />

so the polymer breaks down only after several years<br />

of service. Gear oils are expected to retain their lubricating<br />

effect for about 20 years, while engine oils<br />

are supposed to work reliably for approximately<br />

30,000 kilometers.<br />

VI improvers ensure the viscosity<br />

stays as constant as possible<br />

<strong>Evonik</strong> has supplied VI improvers based on polyalkyl(meth)acrylate<br />

(PAMA) for decades under the<br />

VISCOPLEX® trademark. The molecules consist of a<br />

long polymethacrylate chain with alkyl side chains<br />

that ensure solubility in the base oil. In solution, the<br />

PAMA chains form a ball, which wells up with increasing<br />

temperature. When this happens, the balls<br />

expand, thereby increasing the viscosity of the oil. To<br />

be more exact, VISCOPLEX® ensures that the viscosity<br />

of the solution remains as similar as pos sible compared<br />

to that of the pure base oil without additive.<br />

What the chemists are doing, then, is thwarting<br />

physics: The effect is contrary to the natural behav-<br />

Log T [K]<br />

Expanded<br />

PAMA<br />

Expanded<br />

comb<br />

Oil-insoluble<br />

PAMA backbone<br />

oil-soluble<br />

polyolefin arms