Download - Evonik Industries

Download - Evonik Industries

Download - Evonik Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Study verifies effectiveness of conditioning agent against hair breakage<br />

Shampoos and conditioners that contain the<br />

new silicone conditioning agent ABIL® T Quat<br />

60 from <strong>Evonik</strong> significantly reduce hair fiber<br />

breakage. This is the result of a joint study by<br />

<strong>Evonik</strong>‘s Care Specialties Business Line and<br />

TRI/Princeton of Princeton (New Jersey,<br />

USA), a leading independent research institute<br />

largely devoted to the study of human<br />

hair. ABIL® T Quat 60 also provides outstanding<br />

conditioning features, such as easy combing<br />

and a superior feel in both wet and dry<br />

states. The conditioning agent is universally<br />

suitable for all shampoos and conditioners.<br />

Broken hair fibers are brittle, fray, and<br />

lead to the formation of unsightly split ends.<br />

As a result, they reduce the perception of hair<br />

smoothness, lower shine, and hinder a fluid,<br />

flowing motion. Because consumers rely on<br />

hair care products to solve this problem, improving<br />

the anti-hair breakage functionality<br />

of shampoos and conditioners is an important<br />

issue for the manufacturers of these products.<br />

<strong>Evonik</strong> always substantiates its hair prod uct<br />

solutions through many hair performance<br />

tests. As the experts from <strong>Evonik</strong> and TRI/<br />

Princeton have proven, ABIL® T Quat 60<br />

reduces hair breakage in both shampoos and<br />

conditioners. Their joint study examined the<br />

breakage of hair that was treated with a<br />

shampoo and a conditioner containing ABIL®<br />

T Quat 60. The treated hair underwent defined<br />

tests that are often used to make claims<br />

regarding anti-breakage, strengthening, or<br />

Nitrogen oxide reduction: Lines made from<br />

VESTAMID® compounds satisfy requirements<br />

Illustration of catalytic reduction of nitrogen oxides<br />

<strong>Evonik</strong> offers a variety of VESTAMID® polyamide<br />

12 compounds that help automobile<br />

manufacturers develop systems for reducing<br />

nitrogen oxide in diesel vehicles. All the grades<br />

offered by <strong>Evonik</strong> have performed excellently<br />

in tests, and some are already in use.<br />

A 32.5-percent aqueous solution of urea<br />

serves as the reducing agent in systems developed<br />

today by car makers for the selective<br />

catalytic reduction (SCR) of nitrogen oxides<br />

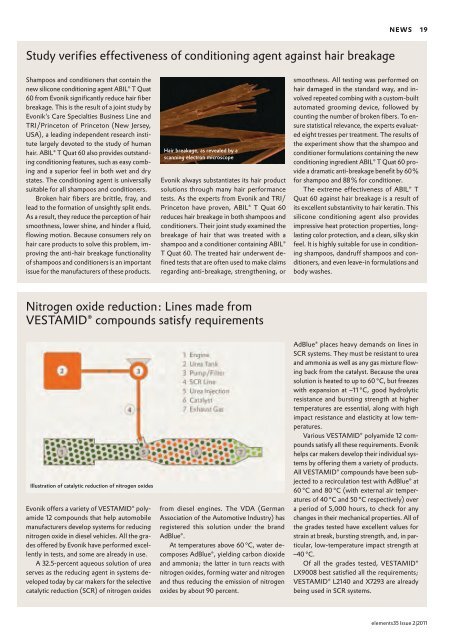

Hair breakage, as revealed by a<br />

scanning electron microscope<br />

from diesel engines. The VDA (German<br />

Association of the Automotive Industry) has<br />

registered this solution under the brand<br />

AdBlue®.<br />

At temperatures above 60 °C, water decomposes<br />

AdBlue®, yielding carbon diox ide<br />

and ammonia; the latter in turn reacts with<br />

nitrogen oxides, forming water and nitro gen<br />

and thus reducing the emission of nitrogen<br />

oxides by about 90 percent.<br />

neWs 19<br />

smoothness. All testing was performed on<br />

hair damaged in the standard way, and in -<br />

volved repeated combing with a custom-built<br />

automated grooming device, followed by<br />

counting the number of broken fibers. To ensure<br />

statistical relevance, the experts evaluated<br />

eight tresses per treatment. The results of<br />

the experiment show that the shampoo and<br />

conditioner formulations containing the new<br />

conditioning ingredient ABIL® T Quat 60 provide<br />

a dramatic anti-breakage benefit by 60%<br />

for shampoo and 88% for conditioner.<br />

The extreme effectiveness of ABIL® T<br />

Quat 60 against hair breakage is a result of<br />

its excellent substantivity to hair keratin. This<br />

silicone conditioning agent also provides<br />

impressive heat protection properties, longlasting<br />

color protection, and a clean, silky skin<br />

feel. It is highly suitable for use in conditioning<br />

shampoos, dandruff shampoos and conditioners,<br />

and even leave-in formulations and<br />

body washes.<br />

AdBlue® places heavy demands on lines in<br />

SCR systems. They must be resistant to urea<br />

and ammonia as well as any gas mixture flowing<br />

back from the catalyst. Because the urea<br />

solution is heated to up to 60 °C, but freezes<br />

with expansion at –11 °C, good hydrolytic<br />

resistance and bursting strength at higher<br />

temperatures are essential, along with high<br />

impact resistance and elasticity at low temper<br />

atures.<br />

Various VESTAMID® polyamide 12 compounds<br />

satisfy all these requirements. <strong>Evonik</strong><br />

helps car makers develop their individual systems<br />

by offering them a variety of products.<br />

All VESTAMID® compounds have been subjected<br />

to a recirculation test with AdBlue® at<br />

60 °C and 80 °C (with external air temperatures<br />

of 40 °C and 50 °C respectively) over<br />

a period of 5,000 hours, to check for any<br />

changes in their mechanical properties. All of<br />

the grades tested have excellent values for<br />

strain at break, bursting strength, and, in particular,<br />

low-temperature impact strength at<br />

–40 °C.<br />

Of all the grades tested, VESTAMID®<br />

LX9008 best satisfied all the requirements;<br />

VESTAMID® L2140 and X7293 are already<br />

being used in SCR systems.<br />

elements35 Issue 2|2011