Download - Evonik Industries

Download - Evonik Industries

Download - Evonik Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

22 DesIGnInG WItH PoLYMeRs<br />

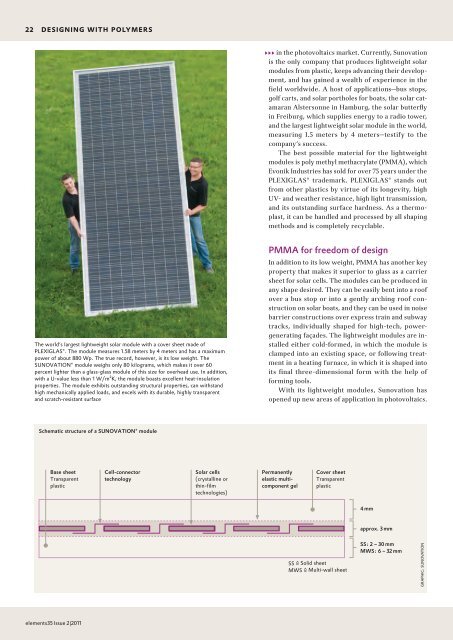

The world‘s largest lightweight solar module with a cover sheet made of<br />

PLEXIGLAS®. The module measures 1.58 meters by 4 meters and has a maximum<br />

power of about 880 Wp. The true record, however, is its low weight. The<br />

SUNOVATION® module weighs only 80 kilograms, which makes it over 60<br />

percent lighter than a glass-glass module of this size for overhead use. In addition,<br />

with a U-value less than 1 W/m²K, the module boasts excellent heat-insulation<br />

properties. The module exhibits outstanding structural properties, can withstand<br />

high mechanically applied loads, and excels with its durable, highly transparent<br />

and scratch-resistant surface<br />

Schematic structure of a SUNOVATION® module<br />

●<br />

Base sheet<br />

Transparent<br />

plastic<br />

elements35 Issue 2|2011<br />

Cell-connector<br />

technology<br />

Solar cells<br />

(crystalline or<br />

thin-film<br />

technologies)<br />

333 in the photovoltaics market. Currently, Sunovation<br />

is the only company that produces lightweight solar<br />

modules from plastic, keeps advancing their development,<br />

and has gained a wealth of experience in the<br />

field worldwide. A host of applications—bus stops,<br />

golf carts, and solar portholes for boats, the solar catamaran<br />

Alstersonne in Hamburg, the solar butterfly<br />

in Freiburg, which supplies energy to a radio tower,<br />

and the largest lightweight solar module in the world,<br />

measuring 1.5 meters by 4 meters—testify to the<br />

company‘s success.<br />

The best possible material for the lightweight<br />

mod ules is poly methyl methacrylate (PMMA), which<br />

<strong>Evonik</strong> <strong>Industries</strong> has sold for over 75 years under the<br />

PLEXIGLAS® trademark. PLEXIGLAS® stands out<br />

from other plastics by virtue of its longevity, high<br />

UV- and weather resistance, high light transmission,<br />

and its outstanding surface hardness. As a thermoplast,<br />

it can be handled and processed by all shaping<br />

methods and is completely recyclable.<br />

PMMA for freedom of design<br />

In addition to its low weight, PMMA has another key<br />

property that makes it superior to glass as a carrier<br />

sheet for solar cells. The modules can be produced in<br />

any shape desired. They can be easily bent into a roof<br />

over a bus stop or into a gently arching roof construction<br />

on solar boats, and they can be used in noise<br />

barrier constructions over express train and subway<br />

tracks, individually shaped for high-tech, power-<br />

generating façades. The lightweight modules are installed<br />

either cold-formed, in which the module is<br />

clamped into an existing space, or following treatment<br />

in a heating furnace, in which it is shaped into<br />

its final three-dimensional form with the help of<br />

forming tools.<br />

With its lightweight modules, Sunovation has<br />

opened up new areas of application in photovoltaics.<br />

Permanently<br />

elastic multicomponent<br />

gel<br />

●<br />

Cover sheet<br />

Transparent<br />

plastic<br />

SS =^ Solid sheet<br />

MWS =^ Multi-wall sheet<br />

4 mm<br />

approx. 3 mm<br />

SS: 2 – 30 mm<br />

MWS: 6 – 32 mm<br />

GRAPHIC: SUNOVATION