Download - Evonik Industries

Download - Evonik Industries

Download - Evonik Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Influence of the engine oil on gas consumption. The measurement<br />

was taken on the engine test stand in Darmstadt, and a<br />

standardized reference oil (RL 191) was used for comparison.<br />

Compared to PAMA, oils with comb polymers can reduce<br />

gas consumption by another 0.9 percent<br />

Comb PAMA<br />

Advantage vs. RL191 [%]<br />

5.0<br />

4.5<br />

4.0<br />

3.5<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

0<br />

4.4<br />

3.5<br />

20 grams by the year 2015—and the new comb polymers<br />

can eliminate up to 2.5 of those grams.<br />

This shows how the chemists at the Oil Addi tives<br />

Business Line are translating the ideas and wishes of<br />

engine developers and lubricant manufacturers into<br />

a chem ical structure of the required additives. They<br />

act as mediator between the growing technical challenges<br />

of engines and drive trains, and the practical<br />

experience of lubricant manufacturers. This requires<br />

close cooperation with formulators in setting the very<br />

specific properties of the lubricant and a continuous<br />

exchange with customers and suppliers.<br />

Every engine in the world is the same in this way:<br />

They all have to run, and run as long and as troublefree<br />

as possible. But this alone is not enough anymore.<br />

Traffic is increasing dramatically worldwide, and is<br />

considered the problem child of climate policy because,<br />

thus far, it has been unable to noticeably curb<br />

traffic-related greenhouse gas emissions.<br />

This is why future vehicles will also be assessed<br />

based on whether engineers and suppliers have<br />

exhausted all potential for the lowest possible fuel<br />

consumption and low emissions. Against this backdrop,<br />

chemically custom-designed additives can help<br />

ensure that advanced engines not only function<br />

optimally but also consume as little fuel as possible.<br />

Doing so is not only in the interest of the driver but<br />

also car manufacturers, engine developers, and the<br />

oil industry—all of whom must ensure that, in the<br />

future, vehicles offer substantially lower emission<br />

levels and greater environmental compatibility. Only<br />

then will traditional drive technologies continue to<br />

be relevant. 777<br />

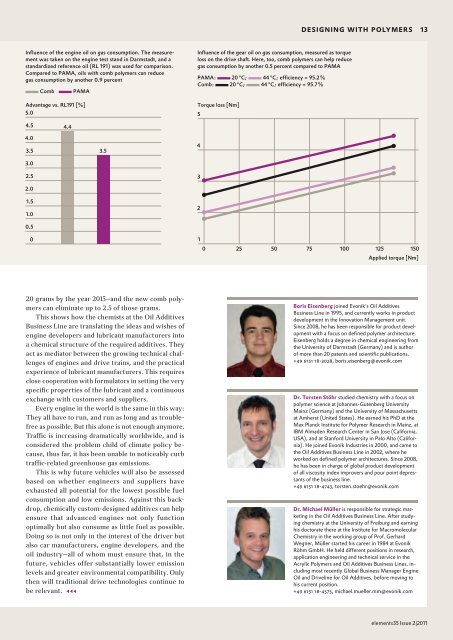

Influence of the gear oil on gas consumption, measured as torque<br />

loss on the drive shaft. Here, too, comb polymers can help reduce<br />

gas consumption by another 0.5 percent compared to PAMA<br />

PAMA: 20 °C; 44 °C; efficiency = 95.2%<br />

Comb: 20 °C; 44 °C; efficiency = 95.7%<br />

Torque loss [Nm]<br />

5<br />

4<br />

3<br />

2<br />

●<br />

●<br />

●<br />

●<br />

DesIGnInG WItH PoLYMeRs 13<br />

1<br />

0 25 50<br />

75 100 125 150<br />

Applied torque [Nm]<br />

Boris eisenberg joined <strong>Evonik</strong>‘s Oil Additives<br />

Business Line in 1995, and currently works in product<br />

development in the Innovation Management unit.<br />

Since 2008, he has been responsible for product development<br />

with a focus on defined polymer architecture.<br />

Eisenberg holds a degree in chemical engineering from<br />

the University of Darmstadt (Germany) and is author<br />

of more than 20 patents and scientific publications.<br />

+49 6151 18-3028, boris.eisenberg@evonik.com<br />

Dr. torsten stöhr studied chemistry with a focus on<br />

polymer science at Johannes-Gutenberg University<br />

Mainz (Germany) and the University of Massachusetts<br />

at Amherst (United States). He earned his PhD at the<br />

Max Planck Institute for Polymer Research in Mainz, at<br />

IBM Almaden Research Center in San Jose (California,<br />

USA), and at Stanford University in Palo Alto (California).<br />

He joined <strong>Evonik</strong> <strong>Industries</strong> in 2000, and came to<br />

the Oil Additives Business Line in 2002, where he<br />

worked on defined polymer architectures. Since 2008,<br />

he has been in charge of global product devel opment<br />

of all viscosity index improvers and pour point depressants<br />

of the business line.<br />

+49 6151 18-4743, torsten.stoehr@evonik.com<br />

Dr. Michael Müller is responsible for strategic marketing<br />

in the Oil Additives Business Line. After studying<br />

chemistry at the University of Freiburg and earning<br />

his doctorate there at the Institute for Macro molecular<br />

Chemistry in the working group of Prof. Gerhard<br />

Wegner, Müller started his career in 1984 at <strong>Evonik</strong><br />

Röhm GmbH. He held different positions in research,<br />

application engineering and technical service in the<br />

Acrylic Polymers and Oil Additives Busi ness Lines, including<br />

most recently Global Business Man ager Engine<br />

Oil and Driveline for Oil Additives, before moving to<br />

his current position.<br />

+49 6151 18-4573, michael.mueller.mm@evonik.com<br />

●<br />

●<br />

●<br />

●<br />

elements35 Issue 2|2011