WO 100 2 - ESAB

WO 100 2 - ESAB

WO 100 2 - ESAB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

GB<br />

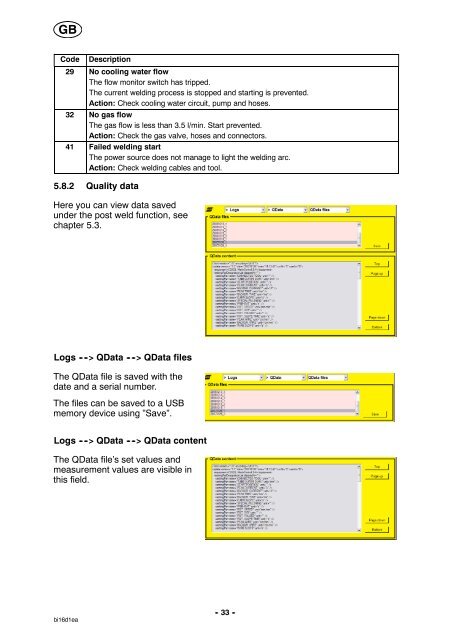

Code Description<br />

29 No cooling water flow<br />

The flow monitor switch has tripped.<br />

The current welding process is stopped and starting is prevented.<br />

Action: Check cooling water circuit, pump and hoses.<br />

32 No gas flow<br />

The gas flow is less than 3.5 l/min. Start prevented.<br />

Action: Check the gas valve, hoses and connectors.<br />

41 Failed welding start<br />

The power source does not manage to light the welding arc.<br />

Action: Check welding cables and tool.<br />

5.8.2 Quality data<br />

Here you can view data saved<br />

under the post weld function, see<br />

chapter 5.3.<br />

Logs - -> QData - -> QData files<br />

The QData file is saved with the<br />

date and a serial number.<br />

ThefilescanbesavedtoaUSB<br />

memory device using ”Save”.<br />

Logs - -> QData - -> QData content<br />

The QData file’s set values and<br />

measurement values are visible in<br />

this field.<br />

bi16d1ea<br />

- 33 -