Scientific Advisory Board - Erich Schmid Institute

Scientific Advisory Board - Erich Schmid Institute

Scientific Advisory Board - Erich Schmid Institute

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ERICH SCHMID INSTITUTE OF MATERIALS SCIENCE<br />

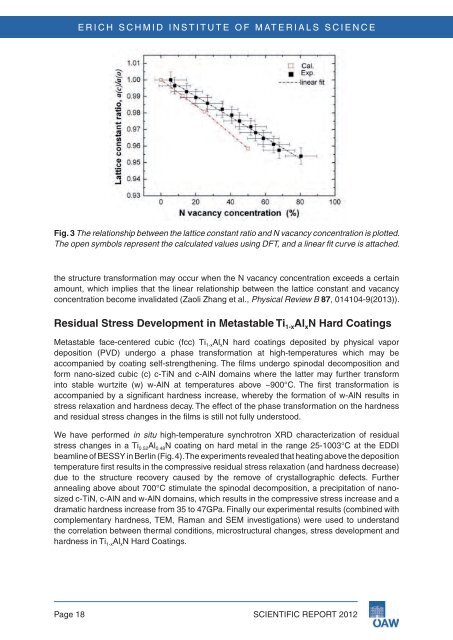

Fig . 3 The relationship between the lattice constant ratio and N vacancy concentration is plotted.<br />

The open symbols represent the calculated values using DFT, and a linear fit curve is attached.<br />

the structure transformation may occur when the n vacancy concentration exceeds a certain<br />

amount, which implies that the linear relationship between the lattice constant and vacancy<br />

concentration become invalidated (Zaoli Zhang et al., Physical Review B 87, 014104-9(2013)).<br />

Residual Stress Development in Metastable Ti 1-xAl xN Hard Coatings<br />

metastable face-centered cubic (fcc) ti 1-xAl xn hard coatings deposited by physical vapor<br />

deposition (pVd) undergo a phase transformation at high-temperatures which may be<br />

accompanied by coating self-strengthening. the films undergo spinodal decomposition and<br />

form nano-sized cubic (c) c-tin and c-Aln domains where the latter may further transform<br />

into stable wurtzite (w) w-Aln at temperatures above ~900°c. the first transformation is<br />

accompanied by a significant hardness increase, whereby the formation of w-Aln results in<br />

stress relaxation and hardness decay. the effect of the phase transformation on the hardness<br />

and residual stress changes in the films is still not fully understood.<br />

We have performed in situ high-temperature synchrotron XRd characterization of residual<br />

stress changes in a ti 0.52Al 0.48n coating on hard metal in the range 25-1003°c at the eddi<br />

beamline of BeSSY in Berlin (fig. 4). the experiments revealed that heating above the deposition<br />

temperature first results in the compressive residual stress relaxation (and hardness decrease)<br />

due to the structure recovery caused by the remove of crystallographic defects. further<br />

annealing above about 700°c stimulate the spinodal decomposition, a precipitation of nanosized<br />

c-tin, c-Aln and w-Aln domains, which results in the compressive stress increase and a<br />

dramatic hardness increase from 35 to 47gpa. finally our experimental results (combined with<br />

complementary hardness, tem, Raman and Sem investigations) were used to understand<br />

the correlation between thermal conditions, microstructural changes, stress development and<br />

hardness in ti 1-xAl xn Hard coatings.<br />

page 18 <strong>Scientific</strong> RepoRt 2012