Scientific Advisory Board - Erich Schmid Institute

Scientific Advisory Board - Erich Schmid Institute

Scientific Advisory Board - Erich Schmid Institute

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ERICH SCHMID INSTITUTE OF MATERIALS SCIENCE<br />

testing with the Afm is a good method to study the deformation behavior of ductile films and to<br />

be able to compare them with other films on soft substrates.<br />

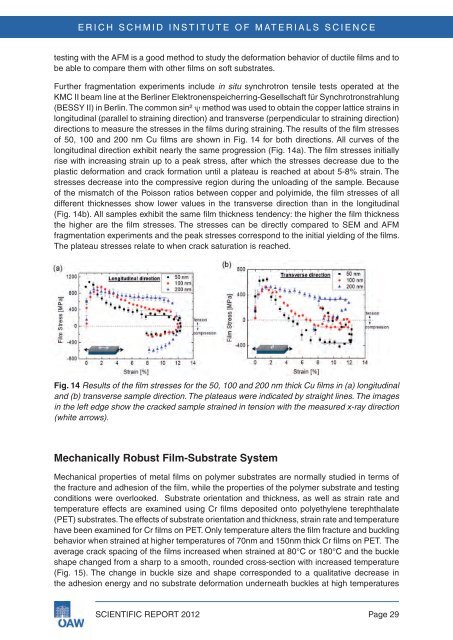

further fragmentation experiments include in situ synchrotron tensile tests operated at the<br />

Kmc ii beam line at the Berliner elektronenspeicherring-gesellschaft für Synchrotronstrahlung<br />

(BeSSY ii) in Berlin. the common sin²ψψ method was used to obtain the copper lattice strains in<br />

longitudinal (parallel to straining direction) and transverse (perpendicular to straining direction)<br />

directions to measure the stresses in the films during straining. the results of the film stresses<br />

of 50, 100 and 200 nm cu films are shown in fig. 14 for both directions. All curves of the<br />

longitudinal direction exhibit nearly the same progression (fig. 14a). the film stresses initially<br />

rise with increasing strain up to a peak stress, after which the stresses decrease due to the<br />

plastic deformation and crack formation until a plateau is reached at about 5-8% strain. the<br />

stresses decrease into the compressive region during the unloading of the sample. Because<br />

of the mismatch of the poisson ratios between copper and polyimide, the film stresses of all<br />

different thicknesses show lower values in the transverse direction than in the longitudinal<br />

(fig. 14b). All samples exhibit the same film thickness tendency: the higher the film thickness<br />

the higher are the film stresses. the stresses can be directly compared to Sem and Afm<br />

fragmentation experiments and the peak stresses correspond to the initial yielding of the films.<br />

the plateau stresses relate to when crack saturation is reached.<br />

Fig . 14 Results of the film stresses for the 50, 100 and 200 nm thick Cu films in (a) longitudinal<br />

and (b) transverse sample direction. The plateaus were indicated by straight lines. The images<br />

in the left edge show the cracked sample strained in tension with the measured x-ray direction<br />

(white arrows).<br />

Mechanically Robust Film-Substrate System<br />

mechanical properties of metal films on polymer substrates are normally studied in terms of<br />

the fracture and adhesion of the film, while the properties of the polymer substrate and testing<br />

conditions were overlooked. Substrate orientation and thickness, as well as strain rate and<br />

temperature effects are examined using cr films deposited onto polyethylene terephthalate<br />

(pet) substrates. the effects of substrate orientation and thickness, strain rate and temperature<br />

have been examined for cr films on pet. only temperature alters the film fracture and buckling<br />

behavior when strained at higher temperatures of 70nm and 150nm thick cr films on pet. the<br />

average crack spacing of the films increased when strained at 80°c or 180°c and the buckle<br />

shape changed from a sharp to a smooth, rounded cross-section with increased temperature<br />

(fig. 15). the change in buckle size and shape corresponded to a qualitative decrease in<br />

the adhesion energy and no substrate deformation underneath buckles at high temperatures<br />

<strong>Scientific</strong> RepoRt 2012 page 29