Scientific Advisory Board - Erich Schmid Institute

Scientific Advisory Board - Erich Schmid Institute

Scientific Advisory Board - Erich Schmid Institute

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ERICH SCHMID INSTITUTE OF MATERIALS SCIENCE<br />

Micro- / Nanomechanics<br />

the knowledge of mechanical properties in small dimensions is essential not only for micronsized<br />

specimens used in semiconductor industry, medical devices, etc. but also for advanced<br />

materials that utilize structural features typically in the micro- and nanometer regime to improve<br />

mechanical performance (see sections deformation, fatigue and fracture, and Synthesis of<br />

Bulk nano-materials and -composites by Severe plastic deformation). Hence, it is of general<br />

interest in materials science to understand the underlying physical processes, which govern the<br />

mechanical response of a wide spectrum of materials. in the last 10 years eSi has developed<br />

several new techniques to investigate the mechanical properties at small length scales. nano-<br />

and micromechanical tests are performed under compression, tension, bending and fatigue<br />

loading. different materials and microstructures are used like single crystals, bi-crystals, and<br />

nano-crystalline metals. this permits the study of the influence of microstructural features (e.g.<br />

grain boundaries) and loading conditions (e.g. monotonic vs. cyclic loading, temperature) on<br />

the plastic deformation behavior and enables the understanding of the underlying processes.<br />

in this section a short overview on the current activities in this field at eSi is given.<br />

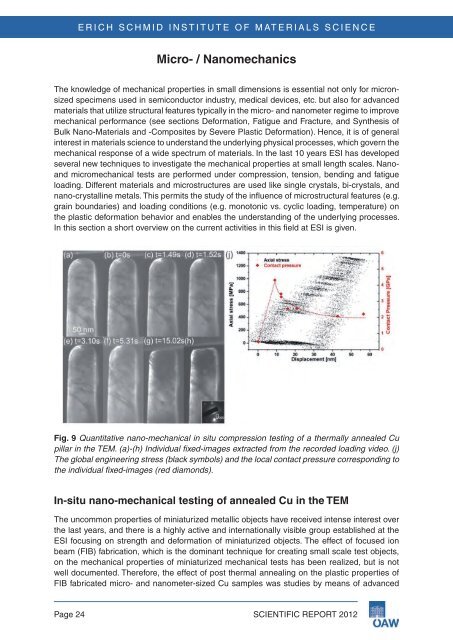

Fig . 9 Quantitative nano-mechanical in situ compression testing of a thermally annealed Cu<br />

pillar in the TEM. (a)-(h) Individual fixed-images extracted from the recorded loading video. (j)<br />

The global engineering stress (black symbols) and the local contact pressure corresponding to<br />

the individual fixed-images (red diamonds).<br />

In-situ nano-mechanical testing of annealed Cu in the TEM<br />

the uncommon properties of miniaturized metallic objects have received intense interest over<br />

the last years, and there is a highly active and internationally visible group established at the<br />

eSi focusing on strength and deformation of miniaturized objects. the effect of focused ion<br />

beam (fiB) fabrication, which is the dominant technique for creating small scale test objects,<br />

on the mechanical properties of miniaturized mechanical tests has been realized, but is not<br />

well documented. therefore, the effect of post thermal annealing on the plastic properties of<br />

fiB fabricated micro- and nanometer-sized cu samples was studies by means of advanced<br />

page 24 <strong>Scientific</strong> RepoRt 2012