Scientific Advisory Board - Erich Schmid Institute

Scientific Advisory Board - Erich Schmid Institute

Scientific Advisory Board - Erich Schmid Institute

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ERICH SCHMID INSTITUTE OF MATERIALS SCIENCE<br />

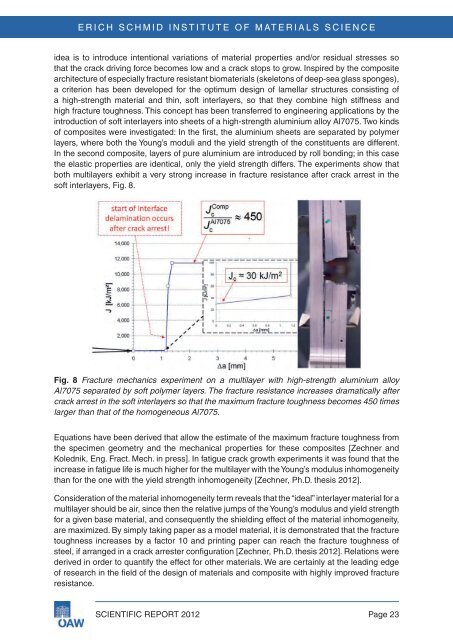

idea is to introduce intentional variations of material properties and/or residual stresses so<br />

that the crack driving force becomes low and a crack stops to grow. inspired by the composite<br />

architecture of especially fracture resistant biomaterials (skeletons of deep-sea glass sponges),<br />

a criterion has been developed for the optimum design of lamellar structures consisting of<br />

a high-strength material and thin, soft interlayers, so that they combine high stiffness and<br />

high fracture toughness. this concept has been transferred to engineering applications by the<br />

introduction of soft interlayers into sheets of a high-strength aluminium alloy Al7075. two kinds<br />

of composites were investigated: in the first, the aluminium sheets are separated by polymer<br />

layers, where both the Young’s moduli and the yield strength of the constituents are different.<br />

in the second composite, layers of pure aluminium are introduced by roll bonding; in this case<br />

the elastic properties are identical, only the yield strength differs. the experiments show that<br />

both multilayers exhibit a very strong increase in fracture resistance after crack arrest in the<br />

soft interlayers, fig. 8.<br />

Fig . 8 Fracture mechanics experiment on a multilayer with high-strength aluminium alloy<br />

Al7075 separated by soft polymer layers. The fracture resistance increases dramatically after<br />

crack arrest in the soft interlayers so that the maximum fracture toughness becomes 450 times<br />

larger than that of the homogeneous Al7075.<br />

equations have been derived that allow the estimate of the maximum fracture toughness from<br />

the specimen geometry and the mechanical properties for these composites [Zechner and<br />

Kolednik, eng. fract. mech. in press]. in fatigue crack growth experiments it was found that the<br />

increase in fatigue life is much higher for the multilayer with the Young’s modulus inhomogeneity<br />

than for the one with the yield strength inhomogeneity [Zechner, ph.d. thesis 2012].<br />

consideration of the material inhomogeneity term reveals that the “ideal” interlayer material for a<br />

multilayer should be air, since then the relative jumps of the Young’s modulus and yield strength<br />

for a given base material, and consequently the shielding effect of the material inhomogeneity,<br />

are maximized. By simply taking paper as a model material, it is demonstrated that the fracture<br />

toughness increases by a factor 10 and printing paper can reach the fracture toughness of<br />

steel, if arranged in a crack arrester configuration [Zechner, ph.d. thesis 2012]. Relations were<br />

derived in order to quantify the effect for other materials. We are certainly at the leading edge<br />

of research in the field of the design of materials and composite with highly improved fracture<br />

resistance.<br />

<strong>Scientific</strong> RepoRt 2012 page 23