Scientific Advisory Board - Erich Schmid Institute

Scientific Advisory Board - Erich Schmid Institute

Scientific Advisory Board - Erich Schmid Institute

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ERICH SCHMID INSTITUTE OF MATERIALS SCIENCE<br />

Plasticity and Fracture<br />

in the 41 years history of eSi, research in the fundamental understanding of plasticity, fatigue and<br />

fracture has brought the institute a lot of international recognition. Research has been devoted<br />

on the one hand to fundamental questions, such as the proper characterization of fatigue and<br />

fracture properties and the scale effects of strength, ductility, and fracture resistance. Another<br />

permanent topic has been to explore the relation between the micro- and nanostructure of<br />

materials and their deformation-, fatigue-, and fracture properties.<br />

it is clear that the durability, i.e. the resistance against the nucleation and growth of defects,<br />

plays a key role in the development of new materials and components. A deep understanding of<br />

the relations between microstructure and properties is a basic prerequisite for the optimization<br />

of the microstructures of materials or components with respect to specific desired properties.<br />

A distinguishing feature of the experimental work at eSi in the recent years has been the<br />

approach to resolve the microstructure-properties relationships by investigating the influence of<br />

the local microstructure on the local material behaviour. this is essential for the understanding<br />

about complex composite or multi-phase materials. interdisciplinary research between the<br />

fields of materials science and digital image correlation (dic) has led to the development of<br />

highly sophisticated experimental techniques that allow us to perform measurements of the<br />

local fracture initiation toughness from quantitative fracture surface analysis and to record the<br />

damage evolution in materials by in situ deformation- and in situ fracture experiments in the<br />

scanning electron microscope (Sem).<br />

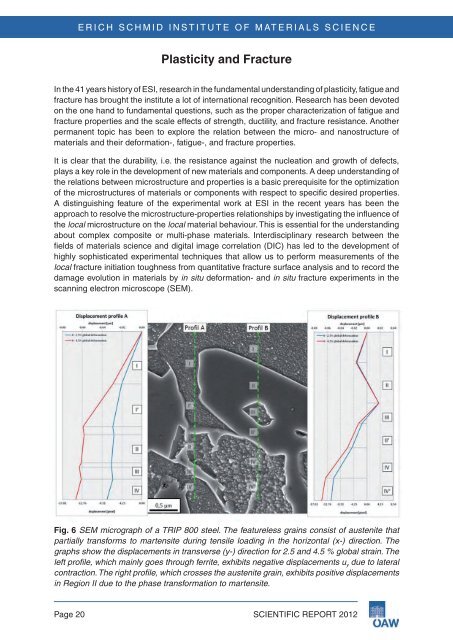

Fig . 6 SEM micrograph of a TRIP 800 steel. The featureless grains consist of austenite that<br />

partially transforms to martensite during tensile loading in the horizontal (x-) direction. The<br />

graphs show the displacements in transverse (y-) direction for 2.5 and 4.5 % global strain. The<br />

left profile, which mainly goes through ferrite, exhibits negative displacements u y due to lateral<br />

contraction. The right profile, which crosses the austenite grain, exhibits positive displacements<br />

in Region II due to the phase transformation to martensite.<br />

page 20 <strong>Scientific</strong> RepoRt 2012