dissertation global and local fracture properties of metal matrix ...

dissertation global and local fracture properties of metal matrix ...

dissertation global and local fracture properties of metal matrix ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Section 7<br />

7. Application <strong>of</strong> ECAP to improve the homogeneity <strong>of</strong> the particle<br />

distribution in MMCs<br />

This work is a part <strong>of</strong> a big project on the deformation <strong>and</strong> <strong>fracture</strong> behavior <strong>of</strong> MMCs. It was<br />

originally planned to investigate (in addition to the cast MMCs) powder <strong>metal</strong>lurgy MMCs<br />

with particle sizes between 100 µm <strong>and</strong> 1 µm. We found, however, that the as-received<br />

material with small particle sizes could not be used for our investigations since the material<br />

<strong>properties</strong> were extremely bad due to the appearance <strong>of</strong> large particle clusters.<br />

This part <strong>of</strong> the work deals with the problem <strong>of</strong> the homogeneity <strong>of</strong> the particle distribution in<br />

powder <strong>metal</strong>lurgy MMCs: a method <strong>of</strong> equal channel angular pressing is proposed to solve<br />

this problem, <strong>and</strong> the effect <strong>of</strong> this method on the <strong>global</strong> <strong>and</strong> <strong>local</strong> <strong>fracture</strong> <strong>properties</strong> is<br />

studied.<br />

7.1. Material<br />

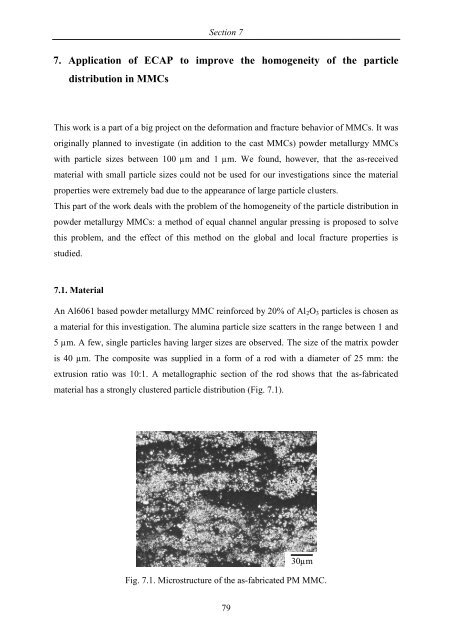

An Al6061 based powder <strong>metal</strong>lurgy MMC reinforced by 20% <strong>of</strong> Al2O3 particles is chosen as<br />

a material for this investigation. The alumina particle size scatters in the range between 1 <strong>and</strong><br />

5 µm. A few, single particles having larger sizes are observed. The size <strong>of</strong> the <strong>matrix</strong> powder<br />

is 40 µm. The composite was supplied in a form <strong>of</strong> a rod with a diameter <strong>of</strong> 25 mm: the<br />

extrusion ratio was 10:1. A <strong>metal</strong>lographic section <strong>of</strong> the rod shows that the as-fabricated<br />

material has a strongly clustered particle distribution (Fig. 7.1).<br />

Fig. 7.1. Microstructure <strong>of</strong> the as-fabricated PM MMC.<br />

79<br />

30µm