dissertation global and local fracture properties of metal matrix ...

dissertation global and local fracture properties of metal matrix ...

dissertation global and local fracture properties of metal matrix ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Section 2<br />

2.2. The influence <strong>of</strong> the <strong>global</strong> microstructure <strong>and</strong> the <strong>matrix</strong> condition on the <strong>global</strong><br />

mechanical <strong>properties</strong> in <strong>metal</strong> <strong>matrix</strong> composites<br />

The influence <strong>of</strong> the <strong>global</strong> microstructural parameters such as the particle volume fraction,<br />

the average particle size, etc., on the <strong>global</strong> mechanical <strong>properties</strong> has been already<br />

investigated in detail. The experimental results can be roughly generalized as follows [7]:<br />

With increasing particle volume fraction, the yield strength <strong>and</strong> the ultimate tensile strength<br />

increase, the ductility <strong>and</strong> the <strong>fracture</strong> toughness decrease, e.g., [8]. For a constant particle<br />

volume fraction, the tensile strength tends to increase with decreasing particle size, e.g.,<br />

[9,10]. No such simple pictures have been found for the more complex <strong>properties</strong> <strong>fracture</strong><br />

toughness <strong>and</strong> fatigue resistance; ambiguous results have been reported here [7, 11-12].<br />

Stronger <strong>matrix</strong> alloys produce stronger composites, e. g. [13,14]; the increase in strength due<br />

to the reinforcement decreases with increasing <strong>matrix</strong> strength; in the case <strong>of</strong> very high<br />

strength alloys, reinforcements may even lead to a reduction in strength [15]. Therefore, one<br />

<strong>of</strong> most important factors affecting the mechanical <strong>properties</strong> <strong>of</strong> MMCs is the heat treatment.<br />

In [16], the effect <strong>of</strong> the heat treatment on mechanical <strong>properties</strong> <strong>of</strong> the PM-MMC Al7093-<br />

15%SiC was investigated. An increase <strong>of</strong> the yield strength with increasing aging time up to<br />

the peak aged condition was found. A further increase <strong>of</strong> aging time led to a slight decrease <strong>of</strong><br />

the yield strength. The dependence <strong>of</strong> the <strong>fracture</strong> strain <strong>and</strong> the strain hardening coefficient<br />

on the aging time demonstrated an opposite character. A good correlation between the<br />

<strong>fracture</strong> strain <strong>and</strong> the strain hardening coefficient was found. It was shown that the <strong>fracture</strong><br />

toughness has an inverse dependence on strength <strong>and</strong> correlates well to the strain hardening<br />

coefficient. Fracture surface inspection revealed the dominance <strong>of</strong> the particle <strong>fracture</strong> for the<br />

solution treated, under-aged, peak-aged, <strong>and</strong> slightly over-aged conditions <strong>of</strong> the <strong>matrix</strong><br />

whereas, in the highly overaged condition, (near-)interface debonding failure dominated.<br />

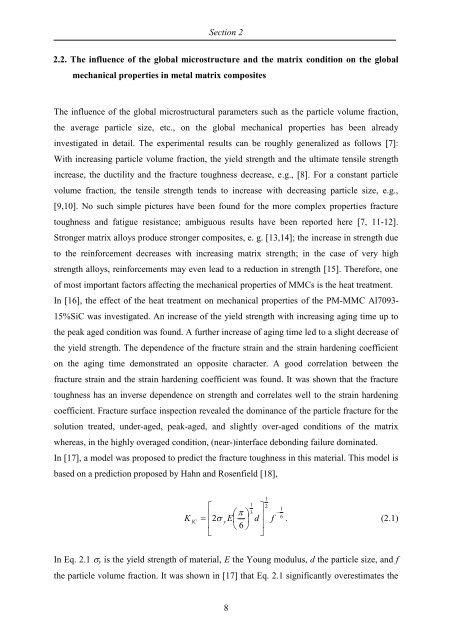

In [17], a model was proposed to predict the <strong>fracture</strong> toughness in this material. This model is<br />

based on a prediction proposed by Hahn <strong>and</strong> Rosenfield [18],<br />

8<br />

1<br />

2<br />

1 ⎡<br />

⎤ 1<br />

3 −<br />

⎢ ⎛π<br />

⎞<br />

6<br />

= 2σ<br />

E⎜<br />

⎟ d⎥<br />

f . (2.1)<br />

⎢ ⎝ 6 ⎠ ⎥<br />

⎣<br />

⎦<br />

K IC<br />

y<br />

In Eq. 2.1 σy is the yield strength <strong>of</strong> material, E the Young modulus, d the particle size, <strong>and</strong> f<br />

the particle volume fraction. It was shown in [17] that Eq. 2.1 significantly overestimates the