development of micro-pattern gaseous detectors – gem - LMU

development of micro-pattern gaseous detectors – gem - LMU

development of micro-pattern gaseous detectors – gem - LMU

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

32 Chapter 3 The Triple GEM Prototype 1.0<br />

3.3.2 Gas Supply System<br />

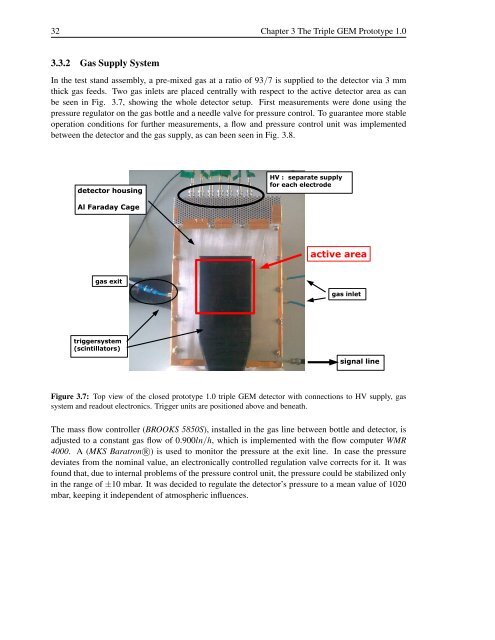

In the test stand assembly, a pre-mixed gas at a ratio <strong>of</strong> 93/7 is supplied to the detector via 3 mm<br />

thick gas feeds. Two gas inlets are placed centrally with respect to the active detector area as can<br />

be seen in Fig. 3.7, showing the whole detector setup. First measurements were done using the<br />

pressure regulator on the gas bottle and a needle valve for pressure control. To guarantee more stable<br />

operation conditions for further measurements, a flow and pressure control unit was implemented<br />

between the detector and the gas supply, as can been seen in Fig. 3.8.<br />

detector housing<br />

Al Faraday Cage<br />

gas exit<br />

triggersystem<br />

(scintillators)<br />

HV : separate supply<br />

for each electrode<br />

active area<br />

gas inlet<br />

signal line<br />

Figure 3.7: Top view <strong>of</strong> the closed prototype 1.0 triple GEM detector with connections to HV supply, gas<br />

system and readout electronics. Trigger units are positioned above and beneath.<br />

The mass flow controller (BROOKS 5850S), installed in the gas line between bottle and detector, is<br />

adjusted to a constant gas flow <strong>of</strong> 0.900ln/h, which is implemented with the flow computer WMR<br />

4000. A (MKS Baratron R○) is used to monitor the pressure at the exit line. In case the pressure<br />

deviates from the nominal value, an electronically controlled regulation valve corrects for it. It was<br />

found that, due to internal problems <strong>of</strong> the pressure control unit, the pressure could be stabilized only<br />

in the range <strong>of</strong> ±10 mbar. It was decided to regulate the detector’s pressure to a mean value <strong>of</strong> 1020<br />

mbar, keeping it independent <strong>of</strong> atmospheric influences.