concept EIA-rapport - Staatsolie

concept EIA-rapport - Staatsolie

concept EIA-rapport - Staatsolie

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Environmental Impact<br />

Assessment for the Construction<br />

and Operation of a Diesel,<br />

Gasoline and LPG Pipeline<br />

Draft <strong>EIA</strong> Report<br />

Report Prepared for<br />

<strong>Staatsolie</strong> Maatschappij Suriname N.V.<br />

Report Number 439414/3<br />

Report Prepared by<br />

June 2012

SRK Consulting: Project No: 439414 <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Page i<br />

Environmental Impact Assessment for the<br />

Construction and Operation of a Diesel,<br />

Gasoline and LPG Pipeline<br />

Draft <strong>EIA</strong> Report<br />

<strong>Staatsolie</strong> Maatschappij Suriname N.V.<br />

SRK Consulting (South Africa) (Pty) Ltd.<br />

The Administrative Building<br />

Albion Spring<br />

183 Main Rd<br />

Rondebosch 7700<br />

Cape Town<br />

South Africa<br />

e-mail: capetown@srk.co.za<br />

website: www.srk.co.za<br />

Tel: +27 (0) 21 659 3060<br />

Fax: +27 (0) 21 685 7105<br />

SRK Project Number 439414<br />

June 2012<br />

Compiled by: Peer Reviewed by:<br />

Sue Reuther<br />

Principal Environmental Consultant<br />

Email: sreuther@srk.co.za<br />

Authors:<br />

Sue Reuther<br />

Chris Dalgliesh<br />

Principal Environmental Consultant<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Final June 2012

1 INTRODUCTION<br />

NON‐TECHNICAL SUMMARY<br />

<strong>EIA</strong> FOR THE CONSTRUCTION OF DIESEL, GASOLINE AND LPG PIPELINES:<br />

<strong>Staatsolie</strong> Maatschappij Suriname N.V. (<strong>Staatsolie</strong>) is<br />

currently expanding the refinery at Tout Lui Faut, about<br />

5 km south of Paramaribo. As part of the refinery<br />

expansion, <strong>Staatsolie</strong> proposes to construct three new<br />

pipelines to take Liquefied Petroleum Gas (LPG) from<br />

OGANE to the refinery and to take diesel and gasoline from<br />

the refinery to the SOL and Suritex depots.<br />

SRK Consulting (South Africa) (Pty) Ltd (SRK) was appointed<br />

by <strong>Staatsolie</strong> as independent consultants to undertake the<br />

Environmental Impact Assessment (<strong>EIA</strong>) process for the<br />

proposed pipelines, in line with the Draft Environmental<br />

Act of 2002 and the Environmental Assessment Guidelines<br />

(August 2009) issued by the Nationaal Instituut voor Milieu<br />

en Ontwikkeling in Suriname (NIMOS).<br />

2 LEGAL REQUIREMENTS<br />

Suriname does not have approved environmental<br />

legislation, although it is currently being developed and<br />

guidelines for environmental assessment have been<br />

released. The <strong>EIA</strong> process for the proposed pipeline project<br />

will comply with the guidelines and other relevant<br />

legislation.<br />

In addition the <strong>EIA</strong> process will be guided by international<br />

best practice, notably standards and guidelines of the<br />

World Bank Group.<br />

<strong>Staatsolie</strong>’s Health, Safety and Environment (HSE) Policy<br />

and Management System have also guided the <strong>EIA</strong> .<br />

3 PROJECT DESCRIPTION<br />

The project includes the construction of three<br />

underground pipelines between the <strong>Staatsolie</strong> refinery at<br />

Tout Lui Faut and Suritex, via the SOL and OGANE sites:<br />

• One diesel and one gasoline pipeline to convey diesel<br />

and gasoline from the <strong>Staatsolie</strong> refinery to SOL and<br />

Suritex; and<br />

• One LPG pipeline to convey LPG from OGANE to the<br />

<strong>Staatsolie</strong> refinery.<br />

<strong>EIA</strong> REPORT<br />

For most of the route, the pipelines will be installed<br />

underneath the western bank of the Suriname River, using<br />

horizontal directional drilling. Continuous sections of up to<br />

1.64 km will be drilled. Drilling entry and/or exit points will<br />

be located at the surface, from where the drill operates<br />

and the pipelines are pulled into the drill hole (see Figure<br />

1). At these points, the pipelines will lie approximately 3 m<br />

below the surface. Between entry and exit points, the<br />

pipelines are expected to lie up to 30 m below the riverbed<br />

(see Figure 2).<br />

Figure 1: Figures showing HDD (top), drilling (middle) and<br />

insertion of pipeline into the drill hole (bottom)<br />

4 ENVIRONMENTAL PROCESS<br />

An <strong>EIA</strong> is a process to identify and assess environmental<br />

effects of a proposed project. The <strong>EIA</strong> process has two<br />

main phases: the Scoping Phase and the Impact<br />

Assessment Phase (the current phase) (see Figure 3).<br />

The purpose of the <strong>EIA</strong> is to:<br />

• Document existing conditions in the study area and the<br />

socio‐economic conditions of affected communities;<br />

• Assess the environmental and socio‐economic impacts<br />

that may result from the project;<br />

• Inform and obtain contributions from stakeholders,<br />

including relevant authorities and the public, and address<br />

their relevant issues and concerns;<br />

Er is een Nederlandse versie van dit document beschikbaar. Maak aub contact met de SRK.

SRK Consulting: <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Summary Pag<br />

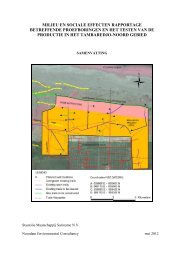

Suritex<br />

OGANE<br />

SOL<br />

Pipeline trenching<br />

portion<br />

Figure 2: Land‐based alignment alternative of pipelines<br />

Approximate alignment of<br />

pipeline underneath the river<br />

using HDD<br />

<strong>Staatsolie</strong><br />

Refinery<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Summary June 2012

SRK Consulting: <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Summary Page iii<br />

• Identify measures to address the impacts assessed; and<br />

• Develop Management Plans, based in part on the<br />

mitigation measures developed in the <strong>EIA</strong> Report.<br />

SCOPING PHASE<br />

Study Plan<br />

NIMOS Review<br />

IMPACT ASSESSMENT PHASE<br />

Specialist Studies<br />

Draft <strong>EIA</strong> Report & Management Plans<br />

Public Consultation<br />

Final <strong>EIA</strong> Report & Management Plans<br />

Submission to NIMOS<br />

NIMOS Review<br />

Recommendations and advice<br />

Figure 3: Overview of the <strong>EIA</strong> process<br />

Public consultation is also an important part of the <strong>EIA</strong> that<br />

runs throughout the process. <strong>EIA</strong> and public participation<br />

activities undertaken are listed in Table 1.<br />

Table 1: <strong>EIA</strong> Activities undertaken<br />

Activity Timeline<br />

Activities undertaken by <strong>Staatsolie</strong> (Screening):<br />

Submission of Terms of Reference (ToR) for<br />

the <strong>EIA</strong> to NIMOS<br />

Oct – Nov 2009<br />

Meetings with directly affected landowners Dec 2010 and<br />

to discuss and obtain feedback on the<br />

project<br />

Jan 2012<br />

Meetings with MAS and District<br />

Oct 2011, Dec<br />

Commissioners to discuss and obtain 2011 and Jan<br />

feedback on the project<br />

2012<br />

Activities undertaken by SRK (Scoping and Impact Assessment):<br />

Preparation of Study Plan for NIMOS review Oct 2011<br />

NIMOS comments on Study Plan Nov 2011<br />

Final Study Plan for submission to NIMOS Feb 2012<br />

Preparation of Draft <strong>EIA</strong> Report (this<br />

document) and Non Technical Summary<br />

Mar – May 2012<br />

Preparation of Management Plans Apr – May 2012<br />

Advertisement of the process to the public Jun 2012<br />

Meetings with stakeholders Jun 2012<br />

The report will be submitted to NIMOS for their comment<br />

and to assist their recommendations regarding the project.<br />

5 AFFECTED ENVIRONMENT<br />

The area in which the pipeline corridor is located has been<br />

developed for over 300 years. Oil‐related activities started<br />

at the <strong>Staatsolie</strong> refinery site in 1988, and the refinery<br />

came into operation in 1997. The corridor is situated in a<br />

peri‐urban and industrial area.<br />

Project activities will be largely restricted to drill pads and<br />

assembly areas. The soils around most drill pads have been<br />

disturbed in the past and the land on which they will be<br />

located are not well suited for agriculture. A thick clay<br />

layer is located below the Suriname River for much of the<br />

pipeline corridor.<br />

The Suriname River has been altered by the construction<br />

of the Afobaka Dam, and river water quality is significantly<br />

impacted by runoff from adjacent residential and industrial<br />

areas.<br />

Three aquifers lie underneath the study area. Groundwater<br />

is withdrawn from the deepest aquifer.<br />

No sensitive ecological areas occur in the study area. A low<br />

marsh forest has re‐established on long‐abandoned land,<br />

while other vacant areas are covered by grasses and<br />

bushes.<br />

The pipeline will run through three Ressorten: Houttuin in<br />

Wanica District and Livorno and Beekhuizen in Paramaribo<br />

District. Historically, Houttuin was a rural farming area, but<br />

local commercial activity is increasing. Beekhuizen and<br />

Livorno are urban to semi urban areas.<br />

The northern section of the study area contains vacant<br />

land and a significant number of light industries,<br />

workshops and warehouses as well as residential areas<br />

along the main roads. Most companies located along the<br />

Suriname River have jetties for loading and unloading.<br />

The southern portion of the study area is characterized by<br />

housing developments along roads and some small<br />

industry and other enterprises. Most companies located<br />

along the river have a jetty or quay. Large tracts of vacant<br />

land lie next to the river, some used for cattle‐grazing.<br />

Thousands of commuters travel from Wanica to<br />

Paramaribo every day, resulting in moderate to high traffic<br />

intensity on Martin Luther King Road and Sir Winston<br />

Churchill Road. Many boats use the Suriname River and<br />

jetties in the study area.<br />

6 IMPACT ASSESSMENT<br />

The impacts of a pipeline are mostly linked to the<br />

sensitivity of the environment along the route and the<br />

extent (or ‘footprint’) of the pipeline and associated<br />

facilities. The proposed route is entirely within disturbed<br />

land or deep underground, and the pipeline is relatively<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Summary June 2012

SRK Consulting: <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Summary Page iv<br />

short. Many impacts are thus likely to be of low<br />

significance, including groundwater, visual, air quality,<br />

noise and vibration, land and river use and climate change<br />

impacts.<br />

The following potentially significant impacts were<br />

assessed:<br />

• Impacts on surface water quality in the Suriname River<br />

mainly during construction, notably the planned disposal<br />

of surplus (non‐toxic) drilling mud into the Suriname<br />

River and runoff of sediments or polluted water from<br />

construction sites. Impacts on water quality are<br />

expected to be insignificant with mitigation due to the<br />

tidal nature of the river, the expected small volume of<br />

pollutants and the absence of sensitive habitats in the<br />

area;<br />

• Impacts on terrestrial and aquatic habitat quality will be<br />

confined to the construction phase when vegetation is<br />

cleared for drill pads and assembly areas and land is<br />

filled to extend drill pads into the river. Impacts on<br />

habitat quality are expected to be of very low (negative)<br />

significance with mitigation as construction sites are<br />

very small and located in highly disturbed areas of no<br />

conservation value;<br />

• The project will generate only limited employment. It is<br />

not expected that new employment will be created by<br />

the pipeline construction, although existing employment<br />

at the contracted firms will be supported. Direct and<br />

indirect employment generated through the project is<br />

expected to be of very low (positive) significance; and<br />

• Construction traffic may affect road and river traffic.<br />

However, the impact is considered to be very low with<br />

mitigation as additional (local) road traffic due to the<br />

pipeline construction is expected to be minimal, and<br />

river‐based activities will only be impacted locally for a<br />

short period of time.<br />

The <strong>EIA</strong> also considered the impacts of possible non‐<br />

routine events, or “risks”, such as the accidental release of<br />

drilling mud during construction and the accidental release<br />

of fuels due to pipeline rupture or leakage. The significance<br />

of these impacts, should an incident take place, was<br />

deemed to be very low after mitigation.<br />

Two management plans were developed by SRK as part of<br />

the <strong>EIA</strong> process, to ensure that proposed mitigation<br />

measures are implemented throughout the project:<br />

• An Environmental Management and Monitoring Plan;<br />

• A Conceptual Decommissioning Plan.<br />

7 CONCLUSION AND WAY FORWARD<br />

The <strong>EIA</strong> Report has identified and assessed the potential<br />

impacts associated with the proposed installation of<br />

pipelines between the <strong>Staatsolie</strong> refinery at Tout Lui Faut<br />

and the SOL and Suritex depots.<br />

By using HDD to install the pipelines, most impacts of the<br />

project will be minimised and of very low or no significance<br />

following the implementation of standard mitigation<br />

measures.<br />

<strong>Staatsolie</strong> is committed to ensuring that the pipelines are<br />

operated to high standards through implementation of the<br />

recommended mitigation measures and ongoing<br />

monitoring of performance. Based on this commitment,<br />

SRK firmly believes and the <strong>EIA</strong> demonstrates that the<br />

negative impacts and risks can be reduced to levels<br />

compliant with international standards or guidelines.<br />

Ultimately NIMOS will consider whether the project<br />

benefits outweigh the potential impacts. The essential<br />

benefit of the project is that pipelines are a proven and<br />

safe method of conveying LPG to the refinery and refinery<br />

products to distributors.<br />

The <strong>EIA</strong> Report is now available for public comments, and<br />

we invite stakeholders to review the report and to<br />

participate in the stakeholder engagement process.<br />

Electronic copies of the <strong>EIA</strong> Report and Summary are<br />

available on the websites of:<br />

• SRK: www.srk.co.za (via the ‘Recent Publications’ and<br />

‘Public Documents’ links); and<br />

• <strong>Staatsolie</strong>: www.staatsolie.com.<br />

A public consultation meeting will be held to present and<br />

discuss the findings of the <strong>EIA</strong> with key stakeholders and<br />

members of the public:<br />

Venue: <strong>Staatsolie</strong> Refinery Training Facility<br />

Date: 23 June 2012<br />

Time: 17h30 – 19h30<br />

Comments or questions can be submitted to Sue Reuther<br />

at SRK Consulting, in Dutch or English, by 19 June 2012 at:<br />

Attention of: Sue Reuther<br />

Postnet Suite #206, Private Bag X18, Rondebosch, 7701,<br />

South Africa<br />

Tel: + 27 21 659 3060; Fax: +27 21 685 7105<br />

E‐mail: sreuther@srk.co.za<br />

Once stakeholders have commented on the information<br />

presented in the <strong>EIA</strong> Report, the Final <strong>EIA</strong> Report will be<br />

prepared and submitted to NIMOS for consideration.<br />

NIMOS will evaluate the environmental and social<br />

sustainability of the proposed project and advise <strong>Staatsolie</strong><br />

of their decision.<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Summary June 2012

1 INLEIDING<br />

NIET‐TECHNISCHE SAMENVATTING:<br />

<strong>EIA</strong> (milieu‐effectenanalyse) t.b.v. het aanleggen van DIESEL‐, BENZINE‐ EN<br />

LPGPIJPLEIDINGEN – <strong>EIA</strong>‐RAPPORT<br />

<strong>Staatsolie</strong> Maatschappij Suriname N.V. (<strong>Staatsolie</strong>) is<br />

momenteel bezig met de uitbreiding van haar raffinaderij<br />

te Tout Lui Faut, welke ligt op een afstand van ongeveer<br />

5 km ten zuiden van Paramaribo. Als onderdeel van de<br />

raffinaderij‐uitbreiding stelt <strong>Staatsolie</strong> voor om drie<br />

nieuwe pijpleidingen aan te leggen om LPG ofwel vloeibaar<br />

gas over te brengen van OGANE naar de raffinaderij en om<br />

diesel en benzine te vervoeren van de raffinaderij naar de<br />

SOL en Suritex.<br />

SRK Consulting (South‐Africa) (Pty) Ltd (SRK) werd door<br />

<strong>Staatsolie</strong> aangewezen als onafhankelijke consultant om<br />

een Environmental Impact Assessment (ofwel Milieu‐<br />

effectenanalyse – <strong>EIA</strong>) te verrichten m.b.t. de<br />

voorgestelde pijpleidingen en wel overeenkomstig de<br />

Concept‐Milieuwet 2002 en de Richtlijnen inzake Milieu‐<br />

analyses (augustus 2009) uitgevaardigd door het Nationaal<br />

Instituut voor Milieu en Ontwikkeling in Suriname<br />

(NIMOS).<br />

2 JURIDISCHE VEREISTEN<br />

Momenteel kent Suriname geen goedgekeurde wetgeving<br />

hoewel men momenteel bezig is met het ontwikkelen<br />

hiervan. Voorts zijn er richtlijnen inzake milieu‐analyses<br />

gepubliceerd. Tijdens het <strong>EIA</strong>‐proces voor het voorgestelde<br />

pijpleidingproject zullen de richtlijnen en andere relevante<br />

wetgeving worden nageleefd.<br />

Voorts zal het <strong>EIA</strong>‐proces worden geleid door<br />

internationale ‘best practices’, in het bijzonder<br />

standaarden en richtlijnen van de World Bank Group.<br />

Het beleid inzake Gezondheid, Veiligheid en Milieu (Health,<br />

Safety and Environment Policy ‐ HSE) en het<br />

Managementsysteem van <strong>Staatsolie</strong> hebben ook als<br />

richtlijn gediend voor de <strong>EIA</strong>.<br />

3 PROJECTBESCHRIJVING<br />

Het project omvat de aanleg van drie ondergrondse<br />

pijpleidingen tussen de <strong>Staatsolie</strong>‐raffinaderij te Tout Lui<br />

Faut en Suritex, via de SOL en OGANE‐locaties:<br />

• Een diesel en een benzinepijpleiding om diesel en<br />

benzine te vervoeren van de <strong>Staatsolie</strong>‐raffinaderij naar<br />

SOL en Suritex; en<br />

• Een LPG‐pijpleiding om LPG van OGANE naar de<br />

<strong>Staatsolie</strong>‐raffinaderij over te brengen.<br />

Voor wat betreft het grootste deel van de route, zullen de<br />

pijpleidingen worden geïnstalleerd onder de westelijke<br />

oever van de Surinamerivier, met gebruikmaking van<br />

horizontaal‐gerichte boorwerkzaamheden (HDD). Er zullen<br />

boorwerkzaamheden worden verricht op ononderbroken<br />

delen van maximaal 1,64 km. De inlaat en/of uitlaatpunten<br />

van de betreffende boorwerkzaamheden zullen zich op de<br />

oppervlakte bevinden van waaruit de boor zal opereren<br />

en de pijpleidingen worden getrokken in het boorgat (zie<br />

Afbeelding 1). Bij deze punten zullen de pijpleidingen<br />

ongeveer 3m onder de oppervlakte komen te liggen.<br />

Tussen de inlaat‐ en uitlaatpunten zullen de pijpleidingen<br />

naar verwachting maximaal 30m onder de rivierbedding<br />

komen te liggen (zie Afbeelding 2).<br />

Afbeelding 1: afbeeldingen van de HDD (bovenaan), de<br />

boorwerkzaamheden (midden) en het invoegen van de<br />

pijpleiding in het boorgat (onderaan)<br />

4 MILIEUPROCES<br />

Een <strong>EIA</strong> is een proces om de milieueffecten van een<br />

voorgesteld project te identificeren en te analyseren. Het<br />

<strong>EIA</strong>‐proces omvat twee hoofdfasen: De Scopingsfase<br />

(ofwel afbakeningsfase) en de Effectenanalysefase (de<br />

huidige fase) (zie Afbeelding 3).<br />

Het doel van de <strong>EIA</strong> is:<br />

• de bestaande condities in het studiegebied alsook de<br />

sociaal‐economische condities van de gemeenschappen<br />

die door het project beïnvloed zullen worden, vast te<br />

leggen;<br />

An English version of this document is available. Please contact SRK.

SRK Consulting: <strong>EIA</strong> <strong>Staatsolie</strong> Pijpleiding – Samenvatting <strong>concept</strong> <strong>EIA</strong>-<strong>rapport</strong> Pag<br />

Suritex<br />

OGANE<br />

SOL<br />

Uitgraving<br />

pijpleiding<br />

Afbeelding 2: Alternatief van op het land‐gebaseerde alignement van de pijpleidingen<br />

Bij benadering aangegeven<br />

alignement van de pijpleiding onder<br />

de rivier met gebruikmaking van<br />

HDD<br />

<strong>Staatsolie</strong><br />

Refinery<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Summary_Dutch June 2012

SRK Consulting: <strong>EIA</strong> <strong>Staatsolie</strong> Pijpleiding – Samenvatting <strong>concept</strong> <strong>EIA</strong>-<strong>rapport</strong> Pagina iii<br />

• de milieu en sociaal‐economische effecten die kunnen<br />

voortvloeien uit het project te analyseren;<br />

• stakeholders, waaronder relevante autoriteiten en het<br />

publiek te informeren en hun bijdrage te verkrijgen,<br />

alsook hun belangrijke vraagstukken en zorgpunten aan<br />

te pakken;<br />

• Het identificeren van maatregelen om de geanalyseerde<br />

effecten aan te pakken; en<br />

• Het ontwikkelen van Managementplannen deels<br />

gebaseerd op de mitigeringsmaatregelen ontwikkeld in<br />

het <strong>EIA</strong>‐<strong>rapport</strong>.<br />

SCOPINGSFASE<br />

Studieplan<br />

Bestudering NIMOS<br />

FASE VAN EFFECTENANALYSE<br />

Specialistische studies<br />

Concept <strong>EIA</strong>-Rapport en managementplannen<br />

Overleg met het publiek<br />

Eind <strong>EIA</strong>-Rapport en managementplannen<br />

Indiening bij het NIMOS<br />

Beoordeling NIMOS<br />

Aanbevelingen en advies<br />

Afbeelding 3: Overzicht van het <strong>EIA</strong>‐proces<br />

Het overleg met het Publiek vormt ook een belangrijk<br />

onderdeel van de <strong>EIA</strong> dat tijdens het heel proces<br />

plaatsvindt. De activiteiten ondernomen ten behoeve van<br />

de <strong>EIA</strong> en de participatie van het publiek zijn opgenomen<br />

in Tabel 1.<br />

Tabel 1: De <strong>EIA</strong>‐activiteiten die zijn verricht<br />

Activiteit Tijdlijn<br />

Activiteiten ondernomen door <strong>Staatsolie</strong> (Screening):<br />

Indiening Terms of Reference (ToR) voor de<br />

<strong>EIA</strong> bij het NIMOS<br />

Bijeenkomst met landeigenaren die direct<br />

beïnvloed zullen worden om het project met<br />

hen te bespreken en feedback van hen te<br />

krijgen in dezen<br />

Bijeenkomsten met de MAS en de<br />

Districtscommissarissen om het project met<br />

hen te bespreken en feedback van hen te<br />

krijgen in dezen<br />

okt‐nov 2009<br />

dec 2010 en<br />

jan 2012<br />

okt 2011, dec<br />

2011 en jan<br />

2012<br />

Activiteiten ondernomen door SRK (Scoping / Effectenanalyse):<br />

Opstellen Studieplan ter beoordeling door het<br />

NIMOS<br />

Het <strong>rapport</strong> zal bij het NIMOS worden ingediend ter<br />

becommentariëring en om hun de gelegenheid te geven<br />

aanbevelingen naar voren te brengen.<br />

5 DE OMGEVING DIE DOOR HET PROJECT<br />

BEINVLOED ZAL WORDEN<br />

okt 2011<br />

Commentaar NIMOS inzake het Studieplan nov 2011<br />

Eind‐studieplan voor indiening bij het NIMOS feb 2012<br />

Opstellen <strong>concept</strong>‐<strong>EIA</strong> <strong>rapport</strong> (dit document)<br />

en een Niet‐technische Samenvatting<br />

mrt‐mei 2012<br />

Opstellen Managementplannen apr‐mei 2012<br />

Aankondiging van het proces aan het publiek juni 2012<br />

Bijeenkomsten met stakeholders juni 2012<br />

Het gebied waarin de corridor van de pijpleiding zich<br />

bevindt, wordt al langer dan 300 jaar ontwikkeld. De olie‐<br />

gerelateerde activiteiten gingen in 1988 op de locatie van<br />

de <strong>Staatsolie</strong>‐raffinaderij van start en de raffinaderij werd<br />

in 1997 in gebruik gesteld. De corridor bevindt zich in een<br />

voorstedelijk en industrieel gebied.<br />

De projectwerkzaamheden zullen voornamelijk beperkt<br />

zijn tot boorvlakken (zogenoemde ‘drill pads’) en<br />

assemblagegebieden. De bodems rondom de meeste<br />

boorvlakken zijn in het verleden verstoord en de grond<br />

waarop deze zullen worden geplaatst, is niet erg geschikt<br />

voor de landbouw. Over een groot deel van de<br />

pijpleidingcorridor ligt er een dikke kleilaag onder de<br />

Surinamerivier.<br />

De Surinamerivier is veranderd door de bouw van de<br />

Afobakadam en de kwaliteit van het rivierwater is<br />

aanzienlijk aangetast door uitstroom van nabijgelegen<br />

woonwijken en industriegebieden.<br />

Er liggen drie aquifers (ofwel waterhoudende grondlagen)<br />

onder het studiegebied. Er wordt grondwater onttrokken<br />

van de diepst gelegen aquifer.<br />

Er komen geen ecologisch‐gevoelige gebieden voor in het<br />

studiegebied. Laag‐zwampbos heeft zich hersteld op land<br />

dat reeds lang verlaten is, terwijl andere braakliggende<br />

gebieden bedekt zijn met gras en struiken.<br />

De pijpleiding zal gaan door drie Ressorten: Houttuin in het<br />

district Wanica, en Livorno en Beekhuizen in het district<br />

Paramaribo. Van oudsher was Houttuin een ruraal<br />

landbouwgebied, maar momenteel is er steeds meer locale<br />

commerciële bedrijvigheid. Beekhuizen en Livorno zijn<br />

stedelijke tot semi‐stedelijke gebieden.<br />

Het noordelijke deel van het studiegebied omvat<br />

braakliggend land en een significant aantal lichte<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Summary_Dutch June 2012

SRK Consulting: <strong>EIA</strong> <strong>Staatsolie</strong> Pijpleiding – Samenvatting <strong>concept</strong> <strong>EIA</strong>-<strong>rapport</strong> Pagina iv<br />

industrieën, werkplaatsen en magazijnen alsook<br />

woonwijken langs de hoofdwegen. De meeste bedrijven<br />

langs de Surinamerivier beschikken over aanlegsteigers<br />

voor inlaad‐ en uitlaadwerkzaamheden.<br />

Het zuidelijke deel van het studiegebied wordt gekenmerkt<br />

door woonwijken langs de wegen en enkele kleine<br />

industrieën en andere ondernemingen. De meeste<br />

bedrijven die langs de rivier liggen, beschikken over een<br />

aanlegsteiger of kade. Er liggen uitgestrekte gebieden<br />

braakliggend land langs de rivier waarvan sommige<br />

worden gebruikt als weide t.b.v. vee.<br />

Duizenden forensen reizen elke dag van Wanica naar<br />

Paramaribo waardoor er matige tot hoge verkeersdrukte<br />

ontstaat op de Martin Luther Kingweg en de Sir Winston<br />

Churchillweg. Veel boten maken gebruik van de<br />

Surinamerivier en aanlegsteigers in het studiegebied.<br />

6 EFFECTENANALYSE<br />

De effecten van een pijpleiding zijn meestal gekoppeld aan<br />

de gevoeligheid van het milieu langs de route en de<br />

omvang (ofwel ‘voetafdruk’ of bedekkingsgebied) van de<br />

pijpleiding en de daaraan gerelateerde faciliteiten. De<br />

voorgestelde route bevindt zich volledig binnen verstoord<br />

land of diep onder de grond en de pijpleiding is relatief<br />

kort. Veel effecten zullen waarschijnlijk van lage<br />

significantie zijn, waaronder de effecten op het<br />

grondwater, de visuele effecten, de effecten op de<br />

waterkwaliteit, het geluid en de trillingen, land‐ en<br />

riviergebruik en de gevolgen van de<br />

klimaatsveranderingen.<br />

De volgende potentiële significante effecten werden<br />

geanalyseerd:<br />

• Effecten op de kwaliteit van het oppervlaktewater in<br />

de Surinamerivier voornamelijk tijdens de<br />

constructiefase, met name de geplande afvoer van<br />

overtollig (niet‐giftige) boorsuspensie in de<br />

Surinamerivier en uitstroom van sedimenten of<br />

verontreinigd water afkomstig van de<br />

constructielocaties. De effecten op de kwaliteit van het<br />

water zullen naar verwachting met mitigatie niet<br />

significant zijn aangezien het in dezen gaat om een<br />

getijderivier, voorts vanwege de verwachte kleine<br />

hoeveelheid verontreinigende stoffen en omdat er geen<br />

gevoelige habitats (ofwel natuurlijke leef‐ en<br />

woongebieden) in het gebied voorkomen;<br />

• Effecten op de kwaliteit van terrestrische (ofwel op het<br />

land voorkomende) en aquatische (ofwel in het water<br />

voorkomende) habitats zullen beperkt blijven tot de<br />

constructiefase wanneer er sprake is van het<br />

verwijderen van vegetatie t.b.v. de boorvlakken en<br />

assemblagegebieden, en de grond wordt opgevuld om<br />

de boorvlakken door te trekken tot in de rivier. De<br />

effecten op de kwaliteit van de habitat zullen met<br />

mitigatie naar verwachting van erg lage (negatieve)<br />

significantie zijn, aangezien de constructielocaties erg<br />

klein zijn en zich bevinden in uitermate verstoorde<br />

gebieden zonder ecologische waarde;<br />

• Het project zal slechts beperkte werkgelegenheid<br />

creëren. Naar verwachting zullen er geen nieuwe<br />

arbeidsplaatsen worden gecreëerd door de aanleg van<br />

de pijpleiding; deze werkzaamheden zullen wel<br />

bevorderlijk zijn voor de huidige werkgelegenheid bij de<br />

gecontracteerde bedrijven. Naar verwachting zal de<br />

directe en indirecte werkgelegenheid gecreëerd door dit<br />

project van erg lage (positieve) significantie zijn; en<br />

• Het verkeer t.b.v. de constructiewerkzaamheden zou<br />

van invloed kunnen zijn op het weg‐ en rivierverkeer.<br />

Dit effect wordt met mitigatie echter beschouwd als<br />

niet significant aangezien het extra (locale) verkeer<br />

t.b.v. de werkzaamheden voor de aanleg van de<br />

pijpleiding naar verwachting minimaal zal zijn en niet<br />

verwacht wordt dat de werkzaamheden op de rivier met<br />

betrekking tot het pijpleidingproject van invloed zullen<br />

zijn op het rivierverkeer in het studiegebied.<br />

De <strong>EIA</strong> heeft eveneens in overweging genomen de effecten<br />

van mogelijke niet‐routinematige gebeurtenissen, ofwel<br />

“risico’s”, zoals accidentele uitstroming van boorsuspensie<br />

tijdens de constructiewerkzaamheden en accidentele<br />

uitstroming van brandstoffen als gevolg van een breuk of<br />

lekkage in de pijpleiding. De significantie van deze<br />

effecten, indien zich een incident zou voordoen, werd<br />

beschouwd als zijnde erg laag na mitigatie.<br />

SRK heeft twee managementplannen opgesteld als<br />

onderdeel van het <strong>EIA</strong>‐proces om te garanderen dat de<br />

voorgestelde mitigeringsmaatregelen tijdens het hele<br />

project worden uitgevoerd:<br />

• Een Plan voor Milieumanagement en ‐Monitoring;<br />

• Een <strong>concept</strong>‐Ontmantelingsplan.<br />

7 CONCLUSIE EN DE VOLGENDE STAPPEN<br />

Het <strong>EIA</strong>‐<strong>rapport</strong> heeft de potentiële effecten die gepaard<br />

gaan met de installatie van pijpleidingen tussen de<br />

<strong>Staatsolie</strong>raffinaderij te Tout Lui Faut, en de SOL‐ en<br />

Suritexdepots geïdentificeerd en geanalyseerd.<br />

Middels gebruikmaking van de HDD om de pijpleidingen te<br />

installeren, zullen de meeste effecten van het project<br />

worden geminimaliseerd en na de uitvoering van<br />

standaard‐mitigeringsmaatregelen van lage significantie<br />

zijn of niet significant.<br />

<strong>Staatsolie</strong> heeft zich gecommitteerd om ervoor te zorgen<br />

dat de pijpleidingen volgens hoge standaarden zullen<br />

functioneren middels de implementatie van de aanbevolen<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Summary_Dutch June 2012

SRK Consulting: <strong>EIA</strong> <strong>Staatsolie</strong> Pijpleiding – Samenvatting <strong>concept</strong> <strong>EIA</strong>-<strong>rapport</strong> Pagina v<br />

mitigeringsmaatregelen en voortgaande monitoring van<br />

het prestatievermogen. Op basis van deze committering<br />

heeft het SRK de vaste overtuiging en de <strong>EIA</strong> wijst uit, dat<br />

de negatieve effecten en de risico’s kunnen worden<br />

gereduceerd tot niveaus welke voldoen aan internationale<br />

standaarden of richtlijnen.<br />

Uiteindelijk zal het NIMOS in overweging nemen of de<br />

voordelen van het project zwaarder wegen dan de<br />

mogelijke negatieve effecten. Het essentiële voordeel van<br />

het project is dat pijpleidingen een bewezen en veilige<br />

methode zijn om LPG naar de raffinaderij, en<br />

raffinaderijproducten naar de distributeurs over te<br />

brengen.<br />

Het <strong>EIA</strong>‐<strong>rapport</strong> is thans beschikbaar voor het publiek voor<br />

becommentariëring en wij nodigen stakeholders uit om<br />

het <strong>rapport</strong> door te nemen en te participeren in het proces<br />

voor betrokkenheid van stakeholders. Er zijn elektronische<br />

versies van het <strong>EIA</strong>‐Rapport en de Samenvatting hiervan<br />

beschikbaar op de websites van:<br />

• SRK: www.srk.co.za (via de links ‘Recent Publications’ en<br />

‘Public Documents’ ); en<br />

• <strong>Staatsolie</strong>: www.staatsolie.com.<br />

Er zal een bijeenkomst voor overleg met het publiek<br />

worden gehouden om de bevindingen van de <strong>EIA</strong> aan de<br />

voornaamste stakeholders en leden van het publiek te<br />

presenteren en deze met hen te bediscussiëren:<br />

Plaats: <strong>Staatsolie</strong> Tout Lui Faut Trainingszaal<br />

Datum: 23 juni 2012<br />

Tijd: 17.30u – 9.30u<br />

Commentaar of vragen kunnen of in het Nederlands of in<br />

het Engels worden opgestuurd naar Sue Reuther bij SRK<br />

Consulting, uiterlijk 19 juli 2012 en wel:<br />

Attention of: Sue Reuther<br />

Postnet Suite #206, Private Bag X18, Rondebosch, 7701,<br />

South Africa<br />

Tel: + 27 21 659 3060; Fax: +27 21 685 7105<br />

E‐mail: sreuther@srk.co.za<br />

Wanneer eenmaal de stakeholders hun commentaar op de<br />

informatie zoals die gepresenteerd is in het <strong>EIA</strong>‐<strong>rapport</strong>,<br />

naar voren hebben gebracht, zal het Eind‐<strong>EIA</strong> <strong>rapport</strong><br />

worden opgesteld en worden ingediend bij het NIMOS ter<br />

overweging. Het NIMOS zal de milieu‐ en sociaal‐<br />

maatschappelijke duurzaamheid van het voorgestelde<br />

project evalueren en de <strong>Staatsolie</strong> op de hoogte stellen<br />

van hun besluit in dezen.<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Summary_Dutch June 2012

SRK Consulting: Project No: 439414 <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Page ii<br />

Table of Contents<br />

1 Introduction .................................................................................................................. 1<br />

1.1 Background of the project ................................................................................................................... 1<br />

1.2 Purpose of this Document ................................................................................................................... 1<br />

1.3 Assumptions and limitations ............................................................................................................... 1<br />

1.4 Structure of the report ......................................................................................................................... 2<br />

2 Regulatory and policy framework and <strong>EIA</strong> process .................................................. 3<br />

2.1 Introduction ......................................................................................................................................... 3<br />

2.2 Suriname legal requirements .............................................................................................................. 3<br />

2.2.1 Legal requirements regarding Environmental Assessment .................................................... 3<br />

2.2.2 Other environmental legal requirements ................................................................................. 4<br />

2.3 International standards, requirements, guidelines .............................................................................. 7<br />

2.4 Corporate requirements ...................................................................................................................... 8<br />

2.5 <strong>EIA</strong> Process ........................................................................................................................................ 8<br />

3 Description of the proposed project ......................................................................... 11<br />

3.1 Project motivation: need and desirability .......................................................................................... 11<br />

3.2 Overview of project area ................................................................................................................... 11<br />

3.3 Description of the proposed project .................................................................................................. 13<br />

3.3.1 General description ............................................................................................................... 13<br />

3.3.2 Pipeline alignment ................................................................................................................. 13<br />

3.3.3 Construction .......................................................................................................................... 15<br />

3.3.4 Operation ............................................................................................................................... 18<br />

3.4 Project alternatives............................................................................................................................ 19<br />

3.4.1 Route alternatives ................................................................................................................. 20<br />

3.4.2 Construction method alternatives .......................................................................................... 20<br />

3.4.3 Transportation alternatives .................................................................................................... 21<br />

4 Description of the affected environment .................................................................. 22<br />

4.1 Biophysical environment ................................................................................................................... 22<br />

4.1.1 Climate and air quality ........................................................................................................... 22<br />

4.1.2 Geology and geomorphology ................................................................................................ 24<br />

4.1.3 Soils, land capability and land use ........................................................................................ 29<br />

4.1.4 Noise ..................................................................................................................................... 33<br />

4.1.5 Water resources .................................................................................................................... 33<br />

4.1.6 Ecology .................................................................................................................................. 37<br />

4.2 Socio-economic environment ............................................................................................................ 39<br />

4.2.1 Overview of Ressorten in the study area .............................................................................. 39<br />

4.2.2 Socio-economic characteristics ............................................................................................. 40<br />

4.2.3 Transport infrastructure ......................................................................................................... 44<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Final June 2012

SRK Consulting: Project No: 439414 <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Page iii<br />

4.3 Planning framework and emergency response ................................................................................ 48<br />

4.3.1 Policies and plans at district and Ressort level ..................................................................... 48<br />

4.3.2 Oil spill response ................................................................................................................... 49<br />

5 Stakeholder engagement ........................................................................................... 50<br />

5.1 Objectives and approach .................................................................................................................. 50<br />

5.2 Previous stakeholder engagement activities .................................................................................... 50<br />

5.3 Impact Assessment Phase stakeholder engagement activities ........................................................ 50<br />

6 Assessment of environmental impacts .................................................................... 52<br />

6.1 Introduction ....................................................................................................................................... 52<br />

6.1.1 Environmental issues identified for the project...................................................................... 53<br />

6.1.2 Specialist input ...................................................................................................................... 54<br />

6.1.3 Impact assessment and methodology ................................................................................... 56<br />

6.1.4 Integration of Studies into the <strong>EIA</strong> Report, and Review ........................................................ 58<br />

6.2 Less significant (or minor) impacts ................................................................................................... 59<br />

6.2.1 Groundwater impacts ............................................................................................................ 59<br />

6.2.2 Visual impacts ....................................................................................................................... 60<br />

6.2.3 Air quality impacts ................................................................................................................. 61<br />

6.2.4 Noise and vibration impacts .................................................................................................. 62<br />

6.2.5 Land and river use impacts ................................................................................................... 63<br />

6.2.6 Climate change impacts ........................................................................................................ 63<br />

6.3 Potential impact: Surface water pollution due to construction activities ........................................... 64<br />

6.4 Potential impact: Loss or deterioration of terrestrial and aquatic habitat during construction .......... 66<br />

6.5 Potential impact: Employment creation............................................................................................. 67<br />

6.6 Potential impact: Disruptions to road and river traffic ....................................................................... 68<br />

6.7 Potential risks .................................................................................................................................... 69<br />

6.7.1 Risk: Accidental release of drilling mud during construction (frac-out) ................................. 69<br />

6.7.2 Risk: Accidental release of hydrocarbons due to pipeline rupture or leakage ...................... 70<br />

6.8 Cumulative impacts ........................................................................................................................... 74<br />

6.8.1 Cumulative impacts of existing activities ............................................................................... 74<br />

6.8.2 Potential cumulative impacts of future activities.................................................................... 74<br />

6.9 Management Plans ........................................................................................................................... 75<br />

6.9.1 Environmental Management and Monitoring Plan ................................................................ 75<br />

6.9.2 Conceptual Decommissioning Plan ...................................................................................... 86<br />

7 Conclusions and recommendations ......................................................................... 90<br />

7.1 Principal findings ............................................................................................................................... 90<br />

7.2 Key recommendations ...................................................................................................................... 92<br />

8 Way forward ................................................................................................................ 93<br />

9 References .................................................................................................................. 95<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Final June 2012

SRK Consulting: Project No: 439414 <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Page iv<br />

List of Tables<br />

Table 2-1: Selected relevant national environmental legislation ........................................................................ 5<br />

Table 2-2: IFC Performance Standards .............................................................................................................. 7<br />

Table 2-3: Activities undertaken during the <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> ................................................................ 10<br />

Table 3-1: Proposed pipelines from <strong>Staatsolie</strong> Refinery .................................................................................. 13<br />

Table 3-2: Specifications of pipeline products .................................................................................................. 19<br />

Table 3-3: Comparison of pipelines versus alternative means of transport ..................................................... 21<br />

Table 4-1: Mean monthly rainfall for Zanderij in 2006 and 2007 ...................................................................... 23<br />

Table 4-2: Temperatures for Zanderij in 2006 and 2007 .................................................................................. 23<br />

Table 4-3: Calculated emission rates for the existing refinery and the SPCS power plant .............................. 24<br />

Table 4-4: Characteristics of soils in the study area ......................................................................................... 30<br />

Table 4-5: Suitability classification of the soils of the study area ..................................................................... 30<br />

Table 4-6: Ambient noise levels around the refinery (in early 2009) and IFC guideline levels ........................ 33<br />

Table 4-7: Physico-chemical characteristics of rivers in the Young Coastal Plain ........................................... 34<br />

Table 4-8: Water quality problems identified in the study area ........................................................................ 36<br />

Table 4-9: SRDP results of aquatic sampling in the Suriname River ............................................................... 38<br />

Table 4-10: Estimated 2010 populations .......................................................................................................... 40<br />

Table 4-11: Households and dwellings ............................................................................................................. 41<br />

Table 4-12: Education levels ............................................................................................................................ 41<br />

Table 4-13: School infrastructure ..................................................................................................................... 42<br />

Table 4-14: Employment characteristics .......................................................................................................... 42<br />

Table 4-15: Access to water and electricity ...................................................................................................... 43<br />

Table 4-16: Health care facilities ...................................................................................................................... 43<br />

Table 4-17: Community Based Organisations .................................................................................................. 43<br />

Table 4-18: Projects planned by the District Council of Paramaribo for 2012 .................................................. 48<br />

Table 6-1: Proposed <strong>EIA</strong> specialist studies and relevant specialists ............................................................... 55<br />

Table 6-2: Criteria used to determine the Consequence of the Impact ............................................................ 56<br />

Table 6-3: Method used to determine the Consequence Score ....................................................................... 56<br />

Table 6-4: Probability Classification ................................................................................................................. 56<br />

Table 6-5: Impact significance ratings .............................................................................................................. 57<br />

Table 6-6: Impact status and confidence classification .................................................................................... 57<br />

Table 6-7: Significance of surface water pollution – Construction.................................................................... 65<br />

Table 6-8: Significance of loss or deterioration of terrestrial and aquatic habitat – Construction .................... 66<br />

Table 6-9: Significance of employment creation – Construction ...................................................................... 67<br />

Table 6-10: Significance of disruptions to road and river traffic – Construction ............................................... 69<br />

Table 6-11: Significance of frac-out, should this occur ..................................................................................... 70<br />

Table 6-12: Potential impacts from pipeline leaks in various environments ..................................................... 72<br />

Table 6-13: Significance of accidental release of hydrocarbons from the pipeline – Operation ...................... 73<br />

Table 6-14: Project-specific management and mitigation measures that must be implemented during the<br />

design phase .............................................................................................................................. 77<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Final June 2012

SRK Consulting: Project No: 439414 <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Page v<br />

Table 6-15: Project-specific management and mitigation measures that must be implemented during the<br />

construction phase ..................................................................................................................... 78<br />

Table 6-16: Project-specific management and mitigation measures that must be implemented during<br />

operations .................................................................................................................................. 84<br />

Table 6-17: Measures recommended for decommissioning ............................................................................ 87<br />

Table 7-1: Summary of potential impacts resulting from the Refinery Expansion Project ............................... 91<br />

List of Figures<br />

Figure 2-1: Overview of the <strong>EIA</strong> process .......................................................................................................... 10<br />

Figure 3-1: Proposed alignment of pipelines .................................................................................................... 12<br />

Figure 3-2: River alignment alternative of the proposed pipelines ................................................................... 14<br />

Figure 3-3: Schematic drawing of drilling operation at entry points ................................................................. 16<br />

Figure 3-4: Proposed cross-section of pipeline bundle .................................................................................... 17<br />

Figure 3-5: Schematic drawing of pipeline at entry / exit points ....................................................................... 18<br />

Figure 4-1: The study area (dark grey) and its surroundings ........................................................................... 22<br />

Figure 4-2: Geological cross section through northern Suriname .................................................................... 25<br />

Figure 4-3: Geology of the study area and surroundings ................................................................................. 26<br />

Figure 4-4: Suriname River clay bottom sediment taken nearshore at the <strong>Staatsolie</strong> refinery ........................ 27<br />

Figure 4-5: Four major physiographic regions of Northern Suriname .............................................................. 28<br />

Figure 4-6: Soil map of the study area ............................................................................................................. 29<br />

Figure 4-7: Historical plantations in the area .................................................................................................... 31<br />

Figure 4-8: Land use and vegetation of the study area .................................................................................... 32<br />

Figure 4-9: Drainage areas in the study area ................................................................................................... 35<br />

Figure 4-10: Hydrogeological section Zanderij-Paramaribo ............................................................................. 37<br />

Figure 4-11: Districts Wanica (left) and Paramaribo (right) and their Ressorten ............................................. 39<br />

Figure 4-12: Traffic count at the bridge over the Saramacca Canal in 2007.................................................... 44<br />

Figure 4-13: Location of various socio-economic facilities and institutions in the study area .......................... 45<br />

Figure 4-14: Jetties between the Tout Lui Faut and Saramacca canals .......................................................... 47<br />

Disclaimer<br />

The opinions expressed in this Report have been based on the information supplied to SRK Consulting<br />

(South Africa) (Pty) Ltd (SRK) by <strong>Staatsolie</strong> Maatschappij Suriname N.V. (<strong>Staatsolie</strong>). SRK has exercised all<br />

due care in reviewing the supplied information. SRK does not accept responsibility for any errors or<br />

omissions in the supplied information and does not accept any consequential liability arising from commercial<br />

decisions or actions resulting from them. Opinions presented in this report apply to the site conditions and<br />

features as they existed at the time of SRK’s investigations, and those reasonably foreseeable. These<br />

opinions do not necessarily apply to conditions and features that may arise after the date of this Report,<br />

about which SRK had no prior knowledge nor had the opportunity to evaluate<br />

Cover image courtesy Australian Pipeline Industry Association (2009).<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Final June 2012

SRK Consulting: Project No: 439414 <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Page vi<br />

List of Abbreviations<br />

ABS Algemeen Bureau voor de Statistiek (General Bureau of Statistics)<br />

ATM Ministerie van Arbeid, Technologische Ontwikkeling en Milieu<br />

(Ministry of Labour, Technological Development and Environment)<br />

bbl barrel<br />

CBO Community Based Organization<br />

DC District Council<br />

DLGP Decentralization and Local Government Strengthening Program<br />

EA Environmental Assessment<br />

EBS N.V. Energiebedrijven Suriname (Suriname Energy Company)<br />

<strong>EIA</strong> Environmental Impact Assessment<br />

EMMP Environmental Management and Monitoring Plan<br />

ESA Environmental Site Assessment<br />

HDD Horizontal Directional Drilling<br />

HSE Health, Safety and Environment<br />

IFC International Finance Corporation<br />

IAP Interested and Affected Party<br />

MAS Maritieme Autoriteit Suriname (Maritime Authority Suriname)<br />

NCCR National Contingency (disaster) Coordination Centre<br />

NIMOS Nationaal Instituut voor Milieu en Ontwikkeling in Suriname<br />

(National Institute for Environment and Development in Suriname)<br />

OPRC Oil Pollution Response and Cooperation<br />

PS Performance Standard<br />

QRA Quantitative Risk Assessment<br />

RC Ressort Council<br />

RHC Regional Health Service<br />

SRK SRK Consulting (South Africa) (Pty) Ltd<br />

SWM Surinaamsche Waterleiding Maatschappij (Suriname Water Company)<br />

WSD Water Supply Division<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Final June 2012

SRK Consulting: Project No: 439414 <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Page 1<br />

1 Introduction<br />

1.1 Background of the project<br />

<strong>Staatsolie</strong> Maatschappij Suriname N.V. (<strong>Staatsolie</strong>) was founded more than 30 years ago on<br />

13 December 1980. The Republic of Suriname is the sole shareholder. The company explores,<br />

produces and refines crude oil. By the end of 2011, more than 1400 oil wells were in production and<br />

annual crude production totalled some 5.9 million barrels (bbl) (some 16 000 bbl per day).<br />

<strong>Staatsolie</strong>’s oil refinery is located at Tout Lui Faut, about 7 km south of Paramaribo in the Wanica<br />

District of Suriname. The refinery site is situated between the Suriname River and Sir Winston<br />

Churchill Road. <strong>Staatsolie</strong> is currently in the process of expanding the refinery to increase<br />

processing capacity. As part of the refinery expansion, <strong>Staatsolie</strong> proposes to construct three new<br />

pipelines to convey Liquefied Petroleum Gas (LPG) from OGANE to the refinery and to take diesel<br />

and gasoline from the refinery to the SOL and Suritex 1 product storage depots.<br />

SRK Consulting (South Africa) (Pty) Ltd (SRK) has been appointed by <strong>Staatsolie</strong> as independent<br />

consultants to undertake the Environmental Impact Assessment (<strong>EIA</strong>) process for the proposed<br />

pipelines as required by the Draft Environmental Act of 2002 and the Environmental Assessment<br />

Guidelines (August 2009) issued by the National Institute for Environment and Development in<br />

Suriname (Nationaal Instituut voor Milieu en Ontwikkeling in Suriname - NIMOS).<br />

1.2 Purpose of this Document<br />

The main purposes of this Draft <strong>EIA</strong> Report are to:<br />

• Describe the proposed project and viable project alternatives;<br />

• Inform stakeholders about the findings of specialist studies and input;<br />

• Identify and assess significant impacts associated with the proposed project;<br />

• Report on proposed mitigation measures to minimise impacts and enhance benefits;<br />

• Provide an overview of (environmental) management plans to be implemented during the<br />

construction, operation and closure phases of the proposed project; and<br />

• Elicit comments from stakeholders that will inform the Final <strong>EIA</strong> Report.<br />

The guiding principles adopted and activities undertaken to ensure that the goals of the <strong>EIA</strong> Report<br />

were met are discussed in the following section.<br />

1.3 Assumptions and limitations<br />

As is standard practice, the Draft <strong>EIA</strong> Report is based on a number of assumptions and is subject to<br />

certain limitations, which should be borne in mind when considering information presented in this<br />

report. SRK is confident that these assumptions and limitations do not compromise the integrity of<br />

the <strong>EIA</strong> Report. Relevant limitations and assumptions are listed below. Limitations and assumptions<br />

that apply specific aspects are also listed in the relevant sections.<br />

• <strong>Staatsolie</strong> engaged key stakeholders prior to the compilation of the Study Plan. Comments and<br />

concerns of stakeholders were incorporated into the Study Plan;<br />

1 <strong>Staatsolie</strong> has acquired the Chevron Corporation in Suriname and, as of 1 September 2011, manages its 20 service<br />

stations, four fuel bunker stations and the depot under the “Suritex” brand. As such, the depot will be referred to as the<br />

‘Suritex depot’ in this report.<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Final June 2012

SRK Consulting: Project No: 439414 <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Page 2<br />

• The Scoping Phase of the <strong>EIA</strong> process included compilation of the Study Plan, which was<br />

submitted to NIMOS. The Study Plan was not released for public comment, although it is<br />

available (electronically) upon request;<br />

• The Draft <strong>EIA</strong> Report (this document) will be released for public comment. In total there will have<br />

been two rounds of public consultation, one managed by <strong>Staatsolie</strong> and the other by SRK;<br />

• It is assumed that specialists were able to obtain sufficient environmental data to draft a<br />

defensible baseline description of the existing environment, noting that the affected environment<br />

has been the subject of previous studies and has been considerably altered by human activities;<br />

• Two pipeline alignment alternatives were initially considered: a terrestrial alignment and an<br />

alignment underneath the Suriname River. As described in the Study Plan, the terrestrial<br />

alignment is no longer considered viable and will not be assessed in the <strong>EIA</strong>. It is assumed that<br />

no major realignment within the river alignment will be required; and<br />

• SRK will make every effort to conform to the principles espoused in international best practice<br />

guidelines and standards, within the constraints of this project.<br />

1.4 Structure of the report<br />

The structure of the report is as follows:<br />

Chapter 1: Introduction<br />

Provides an introduction and background to the proposed project and outlines the purpose of this<br />

document, the <strong>EIA</strong> process and the assumptions and limitation applicable to the study.<br />

Chapter 2: Regulatory and policy framework and <strong>EIA</strong> process<br />

Provides a brief summary and interpretation of the national legislation and guidelines, international<br />

standards and corporate (<strong>Staatsolie</strong>’s) requirements relevant to this study, and outlines the <strong>EIA</strong><br />

process.<br />

Chapter 3: Description of the proposed project<br />

Provides a brief description of the pipeline route and the proposed project.<br />

Chapter 4: Description of the affected environment<br />

Provides a description of the biophysical and social conditions in the study area.<br />

Chapter 5: Stakeholder engagement<br />

Provides an overview of the stakeholder engagement that has been conducted to date and is<br />

proposed for the impact assessment phase.<br />

Chapter 6: Assessment of environmental impacts<br />

Provides a description of the potentially insignificant impacts and an assessment of potentially<br />

significant impacts of the project, as well as recommended mitigation measures, and provides the<br />

introduction to the Management Plans.<br />

Chapter 7: Conclusions and recommendations<br />

Provides the key findings and conclusions of the report.<br />

Chapter 8: Way forward<br />

Concludes the document with an outline of the remaining steps in the <strong>EIA</strong> process.<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Final June 2012

SRK Consulting: Project No: 439414 <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Page 3<br />

2 Regulatory and policy framework and <strong>EIA</strong> process<br />

2.1 Introduction<br />

Suriname is governed in terms of the 1987 Constitution of the Republic of Suriname. A supervisory<br />

body – The Council of State – has the power to veto legislation which it deems to be in violation of<br />

the Constitution. The Suriname legal system is a civil law system, reflecting the country’s Dutch<br />

heritage, although local issues are mainly resolved based on traditional custom. The quality of policy<br />

formulation and administration is uneven.<br />

Suriname does not have an approved national environmental policy and there is no legislation<br />

dealing specifically with environmental management. However, environmental legislation is currently<br />

being developed and guidelines for environmental assessment have been released. The <strong>EIA</strong><br />

process for the proposed pipeline project will comply with the guidelines and other relevant existing<br />

legislation.<br />

In addition to national regulatory requirements of Suriname, the <strong>EIA</strong> process will be guided by<br />

international best practice, notably standards and guidelines such as those prescribed by the World<br />

Bank Group for Bank-funded private sector development projects 2 . The World Bank Group<br />

standards and guidelines include environmental and social guidelines and standards that relate to<br />

the implementation and scope of the <strong>EIA</strong> process. Where applicable, the application of the standards<br />

and guidelines will be modified to reflect the scale of the project and other relevant factors.<br />

<strong>Staatsolie</strong> also has corporate standards and management policies that are relevant to the project<br />

and the <strong>EIA</strong> process, notably its Health, Safety and Environment (HSE) Policy and Management<br />

System.<br />

The legislative, regulatory and institutional requirements guiding the proposed <strong>EIA</strong> process as<br />

described above are discussed in more detail below. Note that other requirements may pertain to the<br />

proposed project, but identification and interpretation of these is beyond the brief of this study. As<br />

such, the list provided below is not intended to be definitive or exhaustive, and serves to highlight<br />

key environmental legislation and obligations only.<br />

The key regulatory requirements pertaining to the proposed expansion project and the environmental<br />

assessment thereof include the following:<br />

• Suriname legislation, regulations and guidelines;<br />

• Corporate environmental policies and standards of <strong>Staatsolie</strong>; and<br />

• International best practice standards, such as the guidelines of the World Bank Group.<br />

2.2 Suriname legal requirements<br />

2.2.1 Legal requirements regarding Environmental Assessment<br />

NIMOS, the technical division of the Ministry of Labour, Technological Development and<br />

Environment (Ministerie van Arbeid, Technologische Ontwikkeling en Milieu - ATM), is responsible<br />

for the development of national environmental legislation and administers the environmental<br />

permitting process in Suriname.<br />

2 The World Bank Group standards are applied as best practice guidelines and not as an investment<br />

requirement.<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Final June 2012

SRK Consulting: Project No: 439414 <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Page 4<br />

A draft Environmental Act (2002) has been developed as a framework law in response to the 1992<br />

Rio declaration. The draft Act lays down rules for the conservation, management and protection of a<br />

sound environment within the framework of sustainable development. The draft Act has been under<br />

consideration by the Council of Ministers for some time and has not yet been promulgated. After<br />

acceptance by the Council of Ministers and the Council of State, the draft Act will be considered by<br />

the National Assembly for promulgation. Nevertheless, the principles in the draft Act provide<br />

guidance for conducting an <strong>EIA</strong> in Suriname. The two principal legal requirements of the draft Act<br />

that are relevant to the <strong>Staatsolie</strong> pipeline project and the <strong>EIA</strong> are the requirements relating to the<br />

preparation and execution of <strong>EIA</strong>s (Section 2 (2.2)), and the requirements relating to permitting<br />

procedures (Section 2 (2.3)).<br />

While there is currently no legislative basis for the assessment of environmental impacts of<br />

development proposals in Suriname, NIMOS has published Guidelines for Environmental<br />

Assessment (EA) in Suriname. The EA Guidelines are being applied by NIMOS as part of the<br />

project permitting process and project developers are expected to comply with the guidelines.<br />

The EA Guidelines series consists of the following volumes:<br />

• Volume I: Generic (2009) – This volume contains general guidelines for determining the need<br />

for an EA, the nature and extent of the analysis required and the procedure that should be<br />

followed in conducting an EA. The guidelines cover aspects such as project screening,<br />

classification of projects, scoping guidelines, public consultation, structure of EA reports and the<br />

EA report review process, including criteria for review and compliance checklist. Project<br />

screening is required to determine the need for and required level of EA. Projects are classified<br />

according to three categories, namely Category A (EA is mandatory), B (some form of<br />

environmental assessment is required) or C (no environmental assessment is required).<br />

The proposed construction of the three pipelines has been classified as a Category A project<br />

under the listing of “Pipelines for oil and/or gas” and a full <strong>EIA</strong> process is therefore required.<br />

• Volume II: Mining (2005) – These guidelines are not relevant to this project.<br />

• Volume III: Forestry (2005) – These guidelines are not relevant to this project.<br />

• Volume IV: Social Impact Assessment (2005) – These guidelines provide an outline of the<br />

requirements for conducting Social Impact Assessment, whether as part of an EA process or<br />

required independently for projects that have potential impacts on the social environment.<br />

• Volume V: Power Generation and Transmission Projects (2005) – These guidelines are not<br />

relevant to this project.<br />

2.2.2 Other environmental legal requirements<br />

A draft Waste Act (2004) has been compiled but not yet promulgated. The draft Act sets out<br />

regulations for the treatment of waste materials to protect the environment, based on the “polluter<br />

pays” principle. Different types of waste materials are identified and rules laid down for adequate<br />

storage, transportation and treatment (including recycling, composting and disposal) of each waste<br />

type. The Act makes provision for the prosecution of transgressors. The draft Waste Act is<br />

synchronised with the draft Environmental Act to ensure that there are no inconsistencies.<br />

Other legal instruments governing environmental management in Suriname, categorised according<br />

to the environmental issues that they address, are presented in Table 2-1 below. Note the table only<br />