concept EIA-rapport - Staatsolie

concept EIA-rapport - Staatsolie

concept EIA-rapport - Staatsolie

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

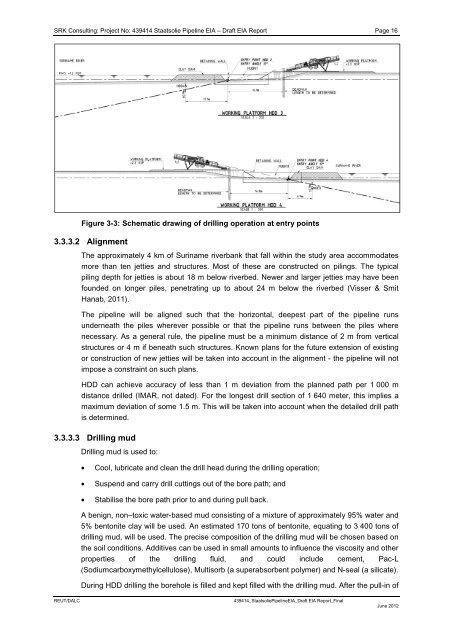

SRK Consulting: Project No: 439414 <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Page 16<br />

Figure 3-3: Schematic drawing of drilling operation at entry points<br />

3.3.3.2 Alignment<br />

The approximately 4 km of Suriname riverbank that fall within the study area accommodates<br />

more than ten jetties and structures. Most of these are constructed on pilings. The typical<br />

piling depth for jetties is about 18 m below riverbed. Newer and larger jetties may have been<br />

founded on longer piles, penetrating up to about 24 m below the riverbed (Visser & Smit<br />

Hanab, 2011).<br />

The pipeline will be aligned such that the horizontal, deepest part of the pipeline runs<br />

underneath the piles wherever possible or that the pipeline runs between the piles where<br />

necessary. As a general rule, the pipeline must be a minimum distance of 2 m from vertical<br />

structures or 4 m if beneath such structures. Known plans for the future extension of existing<br />

or construction of new jetties will be taken into account in the alignment - the pipeline will not<br />

impose a constraint on such plans.<br />

HDD can achieve accuracy of less than 1 m deviation from the planned path per 1 000 m<br />

distance drilled (IMAR, not dated). For the longest drill section of 1 640 meter, this implies a<br />

maximum deviation of some 1.5 m. This will be taken into account when the detailed drill path<br />

is determined.<br />

3.3.3.3 Drilling mud<br />

Drilling mud is used to:<br />

• Cool, lubricate and clean the drill head during the drilling operation;<br />

• Suspend and carry drill cuttings out of the bore path; and<br />

• Stabilise the bore path prior to and during pull back.<br />

A benign, non–toxic water-based mud consisting of a mixture of approximately 95% water and<br />

5% bentonite clay will be used. An estimated 170 tons of bentonite, equating to 3 400 tons of<br />

drilling mud, will be used. The precise composition of the drilling mud will be chosen based on<br />

the soil conditions. Additives can be used in small amounts to influence the viscosity and other<br />

properties of the drilling fluid, and could include cement, Pac-L<br />

(Sodiumcarboxymethylcellulose), Multisorb (a superabsorbent polymer) and N-seal (a silicate).<br />

During HDD drilling the borehole is filled and kept filled with the drilling mud. After the pull-in of<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Final<br />

June 2012