concept EIA-rapport - Staatsolie

concept EIA-rapport - Staatsolie

concept EIA-rapport - Staatsolie

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

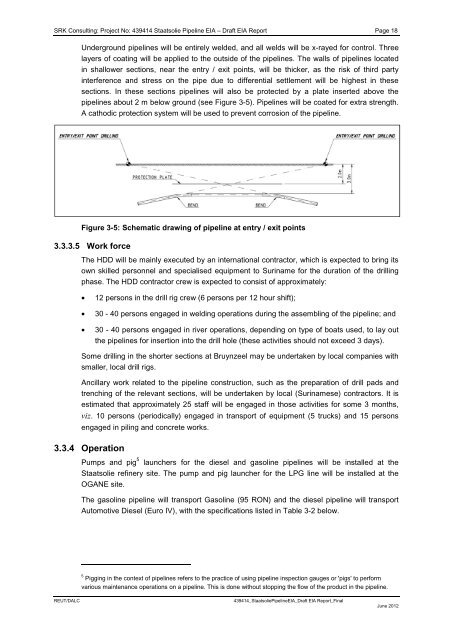

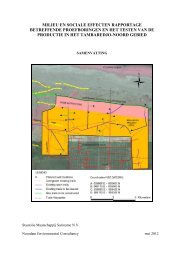

SRK Consulting: Project No: 439414 <strong>Staatsolie</strong> Pipeline <strong>EIA</strong> – Draft <strong>EIA</strong> Report Page 18<br />

Underground pipelines will be entirely welded, and all welds will be x-rayed for control. Three<br />

layers of coating will be applied to the outside of the pipelines. The walls of pipelines located<br />

in shallower sections, near the entry / exit points, will be thicker, as the risk of third party<br />

interference and stress on the pipe due to differential settlement will be highest in these<br />

sections. In these sections pipelines will also be protected by a plate inserted above the<br />

pipelines about 2 m below ground (see Figure 3-5). Pipelines will be coated for extra strength.<br />

A cathodic protection system will be used to prevent corrosion of the pipeline.<br />

Figure 3-5: Schematic drawing of pipeline at entry / exit points<br />

3.3.3.5 Work force<br />

The HDD will be mainly executed by an international contractor, which is expected to bring its<br />

own skilled personnel and specialised equipment to Suriname for the duration of the drilling<br />

phase. The HDD contractor crew is expected to consist of approximately:<br />

• 12 persons in the drill rig crew (6 persons per 12 hour shift);<br />

• 30 - 40 persons engaged in welding operations during the assembling of the pipeline; and<br />

• 30 - 40 persons engaged in river operations, depending on type of boats used, to lay out<br />

the pipelines for insertion into the drill hole (these activities should not exceed 3 days).<br />

Some drilling in the shorter sections at Bruynzeel may be undertaken by local companies with<br />

smaller, local drill rigs.<br />

Ancillary work related to the pipeline construction, such as the preparation of drill pads and<br />

trenching of the relevant sections, will be undertaken by local (Surinamese) contractors. It is<br />

estimated that approximately 25 staff will be engaged in those activities for some 3 months,<br />

viz. 10 persons (periodically) engaged in transport of equipment (5 trucks) and 15 persons<br />

engaged in piling and concrete works.<br />

3.3.4 Operation<br />

Pumps and pig 5 launchers for the diesel and gasoline pipelines will be installed at the<br />

<strong>Staatsolie</strong> refinery site. The pump and pig launcher for the LPG line will be installed at the<br />

OGANE site.<br />

The gasoline pipeline will transport Gasoline (95 RON) and the diesel pipeline will transport<br />

Automotive Diesel (Euro IV), with the specifications listed in Table 3-2 below.<br />

5 Pigging in the context of pipelines refers to the practice of using pipeline inspection gauges or 'pigs' to perform<br />

various maintenance operations on a pipeline. This is done without stopping the flow of the product in the pipeline.<br />

REUT/DALC 439414_<strong>Staatsolie</strong>Pipeline<strong>EIA</strong>_Draft <strong>EIA</strong> Report_Final<br />

June 2012