download - Haas Automation, Inc.

download - Haas Automation, Inc.

download - Haas Automation, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

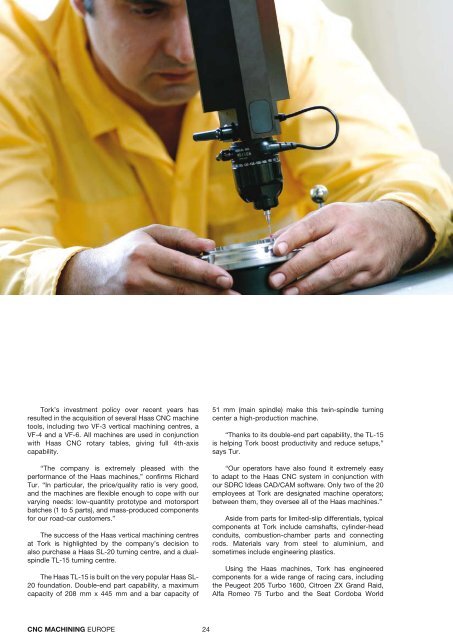

Tork’s investment policy over recent years has<br />

resulted in the acquisition of several <strong>Haas</strong> CNC machine<br />

tools, including two VF- vertical machining centres, a<br />

VF- and a VF- . All machines are used in conjunction<br />

with <strong>Haas</strong> CNC rotary tables, giving full th-axis<br />

capability.<br />

“The company is extremely pleased with the<br />

performance of the <strong>Haas</strong> machines,” confirms Richard<br />

Tur. “In particular, the price/quality ratio is very good,<br />

and the machines are flexible enough to cope with our<br />

varying needs: low-quantity prototype and motorsport<br />

batches (1 to 5 parts), and mass-produced components<br />

for our road-car customers.”<br />

The success of the <strong>Haas</strong> vertical machining centres<br />

at Tork is highlighted by the company’s decision to<br />

also purchase a <strong>Haas</strong> SL- 0 turning centre, and a dualspindle<br />

TL-15 turning centre.<br />

The <strong>Haas</strong> TL-15 is built on the very popular <strong>Haas</strong> SL-<br />

0 foundation. Double-end part capability, a maximum<br />

capacity of 0 mm x 5 mm and a bar capacity of<br />

CNC MACHINING EUROPE<br />

51 mm (main spindle) make this twin-spindle turning<br />

center a high-production machine.<br />

“Thanks to its double-end part capability, the TL-15<br />

is helping Tork boost productivity and reduce setups,”<br />

says Tur.<br />

“Our operators have also found it extremely easy<br />

to adapt to the <strong>Haas</strong> CNC system in conjunction with<br />

our SDRC Ideas CAD/CAM software. Only two of the 0<br />

employees at Tork are designated machine operators;<br />

between them, they oversee all of the <strong>Haas</strong> machines.”<br />

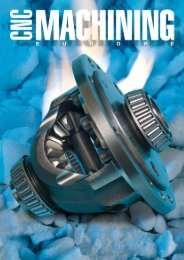

Aside from parts for limited-slip differentials, typical<br />

components at Tork include camshafts, cylinder-head<br />

conduits, combustion-chamber parts and connecting<br />

rods. Materials vary from steel to aluminium, and<br />

sometimes include engineering plastics.<br />

Using the <strong>Haas</strong> machines, Tork has engineered<br />

components for a wide range of racing cars, including<br />

the Peugeot 05 Turbo 1 00, Citroen ZX Grand Raid,<br />

Alfa Romeo 75 Turbo and the Seat Cordoba World