“Finn-Power is the only machine builder that took a position on the ...

“Finn-Power is the only machine builder that took a position on the ...

“Finn-Power is the only machine builder that took a position on the ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CUSTOMER PROFILE<br />

Canadian Manufacturer Fills Bending Needs<br />

with Finn-<str<strong>on</strong>g>Power</str<strong>on</strong>g> Servo Hydraulic Press Brake<br />

In 1984, Luigi Casasanta Sr. establ<str<strong>on</strong>g>is</str<strong>on</strong>g>hed LC Bakery Equipment Services Ltd. in Brantford,<br />

Ontario, Canada, to provide 24/7 maintenance service <strong>on</strong> all types of bakery equipment. As its<br />

well-deserved reputati<strong>on</strong> for reliable service and quality workmanship grew, <str<strong>on</strong>g>the</str<strong>on</strong>g> company moved<br />

into a 6,300 square-foot-facility in 1988. In order to meet <str<strong>on</strong>g>the</str<strong>on</strong>g> equipment demands of h<str<strong>on</strong>g>is</str<strong>on</strong>g> customers,<br />

Casasanta purchased some fabricati<strong>on</strong> equipment and began manufacturing bakery equipment <strong>on</strong> a<br />

small scale.<br />

In 1998, LC Bakery Equipment moved to its present locati<strong>on</strong> were it now occupies a 35,000<br />

square-foot facility. Joining Casasanta and h<str<strong>on</strong>g>is</str<strong>on</strong>g> wife Ernesta in <str<strong>on</strong>g>the</str<strong>on</strong>g> family business were <str<strong>on</strong>g>the</str<strong>on</strong>g>ir three<br />

s<strong>on</strong>s – Robert, Vice President of Engineering; Vic, Vice President of Operati<strong>on</strong>s; and Luigi Jr., Vice<br />

President of Engineering. With many<br />

years of experience in manufacturing<br />

and maintenance of bakery equipment,<br />

LC Bakery Equipment began <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

development its own line of highquality<br />

bakery equipment.<br />

Today, <str<strong>on</strong>g>the</str<strong>on</strong>g> company has evolved<br />

from its humble beginning as a service<br />

oriented company in southwestern<br />

Ontario, to a full-fledged<br />

manufacturing company. According to<br />

Robert Casasanta, Vice President of<br />

Engineering, while service <str<strong>on</strong>g>is</str<strong>on</strong>g> still a vital<br />

part of <str<strong>on</strong>g>the</str<strong>on</strong>g> company operati<strong>on</strong>s, LC<br />

Bakery Equipment <str<strong>on</strong>g>is</str<strong>on</strong>g> focused <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

manufacturing of custom bakery<br />

equipment, including ovens, proofing<br />

systems, flour silo systems, racks, etc.,<br />

for <str<strong>on</strong>g>the</str<strong>on</strong>g> Industrial/Commercial<br />

internati<strong>on</strong>al market. “We will always<br />

maintain our service div<str<strong>on</strong>g>is</str<strong>on</strong>g>i<strong>on</strong> due its<br />

importance as a valued resource to our<br />

customers,” he explains.<br />

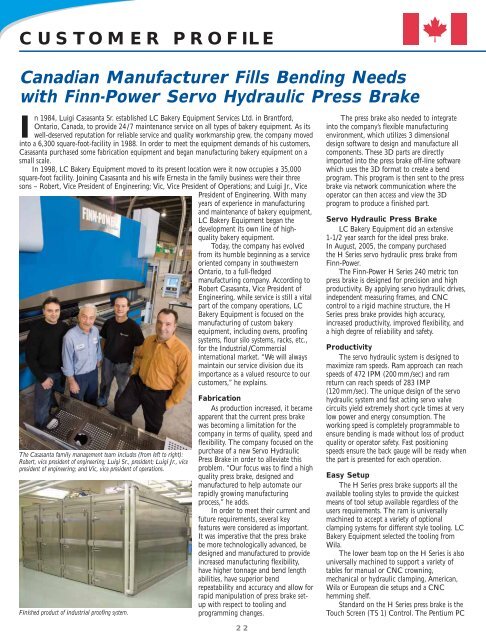

The Casasanta family management team includes (from left to right):<br />

Robert, vice president of engineering; Luigi Sr., president; Luigi Jr., vice<br />

president of engineering; and Vic, vice president of operati<strong>on</strong>s.<br />

Fin<str<strong>on</strong>g>is</str<strong>on</strong>g>hed product of industrial proofing system.<br />

Fabricati<strong>on</strong><br />

As producti<strong>on</strong> increased, it became<br />

apparent <str<strong>on</strong>g>that</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> current press brake<br />

was becoming a limitati<strong>on</strong> for <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

company in terms of quality, speed and<br />

flexibility. The company focused <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

purchase of a new Servo Hydraulic<br />

Press Brake in order to alleviate th<str<strong>on</strong>g>is</str<strong>on</strong>g><br />

problem. “Our focus was to find a high<br />

quality press brake, designed and<br />

manufactured to help automate our<br />

rapidly growing manufacturing<br />

process,” he adds.<br />

In order to meet <str<strong>on</strong>g>the</str<strong>on</strong>g>ir current and<br />

future requirements, several key<br />

features were c<strong>on</strong>sidered as important.<br />

It was imperative <str<strong>on</strong>g>that</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g> press brake<br />

be more technologically advanced, be<br />

designed and manufactured to provide<br />

increased manufacturing flexibility,<br />

have higher t<strong>on</strong>nage and bend length<br />

abilities, have superior bend<br />

repeatability and accuracy and allow for<br />

rapid manipulati<strong>on</strong> of press brake setup<br />

with respect to tooling and<br />

programming changes.<br />

22<br />

The press brake also needed to integrate<br />

into <str<strong>on</strong>g>the</str<strong>on</strong>g> company’s flexible manufacturing<br />

envir<strong>on</strong>ment, which utilizes 3 dimensi<strong>on</strong>al<br />

design software to design and manufacture all<br />

comp<strong>on</strong>ents. These 3D parts are directly<br />

imported into <str<strong>on</strong>g>the</str<strong>on</strong>g> press brake off-line software<br />

which uses <str<strong>on</strong>g>the</str<strong>on</strong>g> 3D format to create a bend<br />

program. Th<str<strong>on</strong>g>is</str<strong>on</strong>g> program <str<strong>on</strong>g>is</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>n sent to <str<strong>on</strong>g>the</str<strong>on</strong>g> press<br />

brake via network communicati<strong>on</strong> where <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

operator can <str<strong>on</strong>g>the</str<strong>on</strong>g>n access and view <str<strong>on</strong>g>the</str<strong>on</strong>g> 3D<br />

program to produce a fin<str<strong>on</strong>g>is</str<strong>on</strong>g>hed part.<br />

Servo Hydraulic Press Brake<br />

LC Bakery Equipment did an extensive<br />

1-1/2 year search for <str<strong>on</strong>g>the</str<strong>on</strong>g> ideal press brake.<br />

In August, 2005, <str<strong>on</strong>g>the</str<strong>on</strong>g> company purchased<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> H Series servo hydraulic press brake from<br />

Finn-<str<strong>on</strong>g>Power</str<strong>on</strong>g>.<br />

The Finn-<str<strong>on</strong>g>Power</str<strong>on</strong>g> H Series 240 metric t<strong>on</strong><br />

press brake <str<strong>on</strong>g>is</str<strong>on</strong>g> designed for prec<str<strong>on</strong>g>is</str<strong>on</strong>g>i<strong>on</strong> and high<br />

productivity. By applying servo hydraulic drives,<br />

independent measuring frames, and CNC<br />

c<strong>on</strong>trol to a rigid <str<strong>on</strong>g>machine</str<strong>on</strong>g> structure, <str<strong>on</strong>g>the</str<strong>on</strong>g> H<br />

Series press brake provides high accuracy,<br />

increased productivity, improved flexibility, and<br />

a high degree of reliability and safety.<br />

Productivity<br />

The servo hydraulic system <str<strong>on</strong>g>is</str<strong>on</strong>g> designed to<br />

maximize ram speeds. Ram approach can reach<br />

speeds of 472 IPM (200 mm/sec) and ram<br />

return can reach speeds of 283 IMP<br />

(120 mm/sec). The unique design of <str<strong>on</strong>g>the</str<strong>on</strong>g> servo<br />

hydraulic system and fast acting servo valve<br />

circuits yield extremely short cycle times at very<br />

low power and energy c<strong>on</strong>sumpti<strong>on</strong>. The<br />

working speed <str<strong>on</strong>g>is</str<strong>on</strong>g> completely programmable to<br />

ensure bending <str<strong>on</strong>g>is</str<strong>on</strong>g> made without loss of product<br />

quality or operator safety. Fast <str<strong>on</strong>g>positi<strong>on</strong></str<strong>on</strong>g>ing<br />

speeds ensure <str<strong>on</strong>g>the</str<strong>on</strong>g> back gauge will be ready when<br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> part <str<strong>on</strong>g>is</str<strong>on</strong>g> presented for each operati<strong>on</strong>.<br />

Easy Setup<br />

The H Series press brake supports all <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

available tooling styles to provide <str<strong>on</strong>g>the</str<strong>on</strong>g> quickest<br />

means of tool setup available regardless of <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

users requirements. The ram <str<strong>on</strong>g>is</str<strong>on</strong>g> universally<br />

<str<strong>on</strong>g>machine</str<strong>on</strong>g>d to accept a variety of opti<strong>on</strong>al<br />

clamping systems for different style tooling. LC<br />

Bakery Equipment selected <str<strong>on</strong>g>the</str<strong>on</strong>g> tooling from<br />

Wila.<br />

The lower beam top <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> H Series <str<strong>on</strong>g>is</str<strong>on</strong>g> also<br />

universally <str<strong>on</strong>g>machine</str<strong>on</strong>g>d to support a variety of<br />

tables for manual or CNC crowning,<br />

mechanical or hydraulic clamping, American,<br />

Wila or European die setups and a CNC<br />

hemming shelf.<br />

Standard <strong>on</strong> <str<strong>on</strong>g>the</str<strong>on</strong>g> H Series press brake <str<strong>on</strong>g>is</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g><br />

Touch Screen (TS 1) C<strong>on</strong>trol. The Pentium PC