Performance of Special Extinguishment Agents for ... - UL.com

Performance of Special Extinguishment Agents for ... - UL.com

Performance of Special Extinguishment Agents for ... - UL.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Issued: September 30, 2008<br />

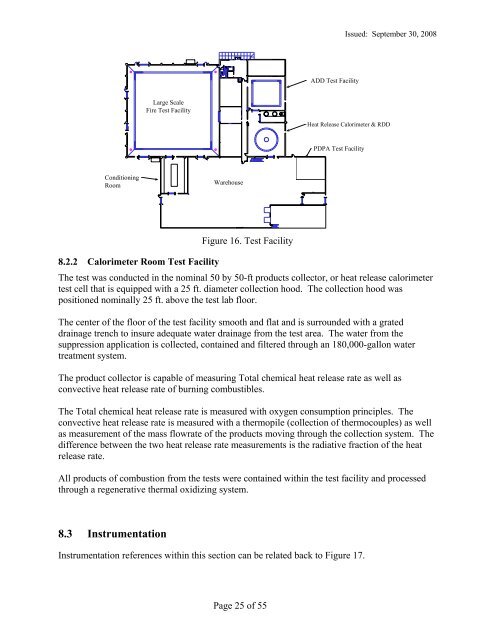

ADD Test Facility<br />

Large Scale<br />

Fire Test Facility<br />

Heat Release Calorimeter & RDD<br />

PDPA Test Facility<br />

Conditioning<br />

Room<br />

Warehouse<br />

8.2.2 Calorimeter Room Test Facility<br />

Figure 16. Test Facility<br />

The test was conducted in the nominal 50 by 50-ft products collector, or heat release calorimeter<br />

test cell that is equipped with a 25 ft. diameter collection hood. The collection hood was<br />

positioned nominally 25 ft. above the test lab floor.<br />

The center <strong>of</strong> the floor <strong>of</strong> the test facility smooth and flat and is surrounded with a grated<br />

drainage trench to insure adequate water drainage from the test area. The water from the<br />

suppression application is collected, contained and filtered through an 180,000-gallon water<br />

treatment system.<br />

The product collector is capable <strong>of</strong> measuring Total chemical heat release rate as well as<br />

convective heat release rate <strong>of</strong> burning <strong>com</strong>bustibles.<br />

The Total chemical heat release rate is measured with oxygen consumption principles. The<br />

convective heat release rate is measured with a thermopile (collection <strong>of</strong> thermocouples) as well<br />

as measurement <strong>of</strong> the mass flowrate <strong>of</strong> the products moving through the collection system. The<br />

difference between the two heat release rate measurements is the radiative fraction <strong>of</strong> the heat<br />

release rate.<br />

All products <strong>of</strong> <strong>com</strong>bustion from the tests were contained within the test facility and processed<br />

through a regenerative thermal oxidizing system.<br />

8.3 Instrumentation<br />

Instrumentation references within this section can be related back to Figure 17.<br />

Page 25 <strong>of</strong> 55